Multitasking Machining Center Cuts Process Steps as Well as Metal

Consistent queue delays between the lathe and the drilling machine led Koso KentIntrol to purchase a multitasking machine from Starrag that was capable of doing both.

UK-based Koso KentIntrol’s investment in a Heckert 630 DBF horizontal machining center from Starrag is paying off in the machining of valve bodies, not least because the machine’s ability for single-setup milling, turning and drilling has eliminated the need for two separate machines — and all the associated resetting and queuing times — to produce finished workpieces.

“In addition to replacing separate machining operations, the Heckert DBF has effectively simplified the production process by allowing us to load once with raw material, undertake complete machining, then unload a finished part ready for inspection. That also means we’re effectively getting more parts per week from that machine than we were using separate machines,” says Richard Addy, machine shop manager.

Combining Operations into Fewer Setups

Koso KentIntrol, founded in 1967 as Introl, is a worldwide supplier of a range of choke, control and butterfly valves as well as actuators and instruments for industries such as oil and gas, petrochemical and power generation. The company specifically purchased the Heckert DBF to increase capacity of the machining of valve and globe bodies with flange outlet bore sizes ranging from 1 to 6 inches. These bodies are made from a variety of materials, from carbon steels to super duplex and Inconel.

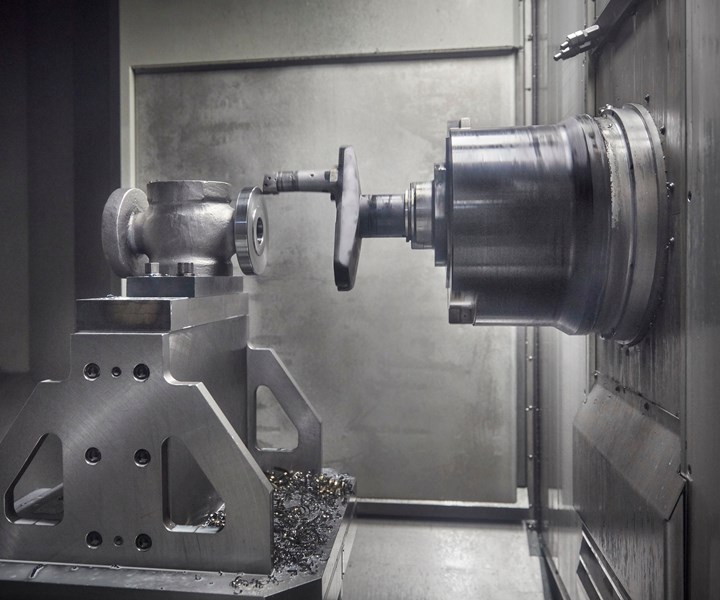

The Starrag Heckert 630 DBF spindle head comprises a faceplate with integrated work spindle and CNC radial facing slide. Here, the head is positioned for turning on this flange.

Previously, the bodies underwent operations on two machines. First, a lathe produced the flange and plug-way in three operations. Then, the part moved to a drill for a final operation. Beforehand, it often sat in a queue until the drill was free. Recognizing the need to increase capacity and capitalizing on its existing relationship with Starrag, Koso KentIntrol selected the Heckert 630 DBF, which uses 630- by 630-mm pallets. The machine’s X-, Y- and Z-axis travels measure 1,070 , 870 and 1,200 mm, respectively, with rapid traverse speeds of 40, 40 and 60 m/min., respectively. The machine also has a ±35-mm U axis for turning as well as a 45-kW (1,700-Nm) spindle.

Originally, the process involved the following steps:

- Load the lathe

- Set up and machine first flange

- Set up and machine second flange

- Set up and machine the plug-way

- Move the part to the drilling cell

- Set up and drill

With the DBF, the strategy for angle bodies is to machine complete in one setup. For glob bodies, it takes two setups: one for machining and drilling the plug-way and one for the flanges.

Taking Full Advantage

The Heckert 630 DBF was not the company’s first Starrag machine. An older Scharmann Ecoforce HT2 with integrated P600 facing head had also served as a single-setup machine tool for larger workpieces at another of the company’s facilities focusing on heavy machining, Mr. Addy says.

“We’ve proven the reliability and consistent high-quality machining results from our Starrag machines. Coupled with the fact that we’ve always received excellent aftermarket backup and support from the company, it made complete sense to continue that single-source association when we needed to address the throughput needs of our smaller valve bodies,” Mr. Addy says.

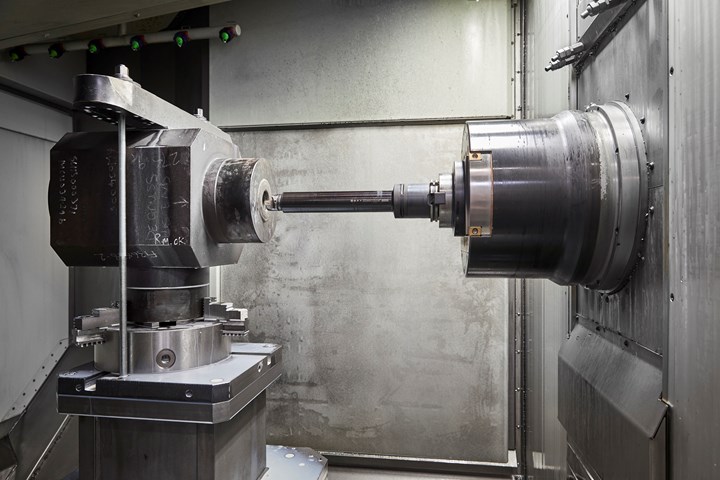

For milling and drilling, the DBF work spindle is arranged in a central position.

The Heckert DBF machine features an integral U axis that houses Starrag’s DBF multitasking head for a range of internal and external machining operations. The spindle head comprises a faceplate with integrated work spindle and CNC radial facing slide. For turning on a fixed workpiece, the rotating turning tool — which has an axial runout of about 5 to 6 microns — can be radially adjusted by ±70 mm. In addition to external, internal and face turning, the head also permits conical and contour turning thanks to the radial facing slide’s NC axis. For milling and drilling, the work spindle is arranged in its central position.

Mr. Addy says the shop makes good use of the machine’s 3,500-rpm spindle, often applying a high-feed Capto milling cutter on carbon steel (WCB) at speeds of 850 rpm and feeds of 3,000 mm/min. He continues: “The machine is really rigid, and on softer materials, we are taking cuts of 2 to 3 mm deep. On duplex bodies, for example, we’re taking 3-mm cuts at speeds and feeds of 60 m/min. and 0.25 mm/rev. But it is a careful balance between cutting depths and speeds and tool wear; we aim to prolong tool life as much as we can. This is especially so when milling the rear of flanges, an operation that can be particularly onerous on the wear of the slitting saws used.”

Related Content

Controlling Extreme Cutting Conditions in Large-Part Machining

Newly patented technologies for controlling chatter and vibration during milling, turning and boring operations promise to drastically reduce production time and increase machining performance.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreBuilding an Automation Solution From the Ground Up

IMTS 2022 provides visitors the opportunity to meet with product experts to design automation solutions from scratch.

Read MoreHow to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.

Read MoreRead Next

From-Scratch CNC Post Processor Lets Dual-Toolhead Mill-Turn Shine

A dual-toolhead multitasking machine made coordination of tool paths difficult, if not impossible. A new post processor for use with Mastercam Mill-Turn resulted in smooth programming of tight-tolerance tool paths using both toolheads.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)