New Users Are Adopting Simulation Software

Even though the market for NC simulation software is mature, that doesn’t mean that new users cannot adopt it. In fact, one CGTech representative lists four reasons why shops that had never considered simulation software before are now opting for it.

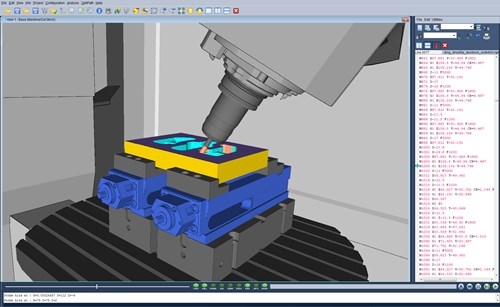

I might have thought that NC simulation software was a mature market. CGTech’s Vericut software, which accurately models CNC machine tools in order simulate the postprocessed version of an NC program, has been available for years—long enough for shops able to benefit from this simulation to have found it. Yet when I recently spoke with a CGTech representative, he said that in fact new business is surging. Shops that have never considered simulation software before are opting for it now.

The company points to various reasons for this. They include:

1. Solid models. In past decades, it wasn’t necessarily true that shops were programming with solid models. Today, the use of solid models is commonplace. Broader availability of solid models for workpieces, cutting tools and machines makes program simulation easier to implement.

2. Higher value work. Particularly for U.S. manufacturers, some of the most lucrative machining opportunities involve parts that are geometrically challenging and/or made from a challenging material. Where the part value is higher, the value of avoiding an error or collision that could damage the part becomes that much higher as well.

3. Capacity constraints. Many shops today have enough work that they are challenged to schedule it all. Performing program prove-out on the machine, therefore, becomes a costly use of machine capacity. Better to prove out the program with software instead.

4. Five axis machining. This is the big one that CGTech sees. Many shops installing their first five-axis machine tool are justifiably cautious about the complexity of this machine’s movements. Simulating the five-axis job before it runs offers a way to safeguard this sophisticated machine.

Related Content

-

Finally, A Comprehensive Software Solution Designed for Small Job Shops

Zel X from Siemens is an integrated software application that consolidates collaboration, design, manufacturing, and operations into a comprehensive, easy-to-use solution. From RFQ to delivery, it’s a more efficient way to handle quotes, manage jobs, make parts, and collaborate with teams of all sizes.

-

When to Use Custom Macros With a CAM System

Custom macros can offer benefits even when using a CAM system to prepare programs – but must be implemented with the right considerations.

-

IMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)