November 2019 Product Spotlight: 5-Axis Machining

This month’s Modern Equipment Review Spotlight focuses on five-axis machining technologies.

This month’s product spotlight, based on Modern Machine Shop magazine’s Modern Equipment Review Spotlight, features a selection of the product releases we have recently published pertaining to five-axis machining technologies, including machines and CAD/CAM software. More product releases can be found in our Zone dedicated to five-axis machine tools.

Chiron Variocell Pallet

The Chiron Variocell Pallet automation cell enables the company’s FZ/DZ 16 five-axis VMC to produce small batches of a variety of workpieces productively and flexibly. Different raw parts can be clamped in one of 10 pallets mounted on a rotary table. The handling system guides one raw part after another to the machining center and removes the machined workpieces together with the pallet after the machining process is complete. A palletized part can also be machined while another is loaded. Read more.

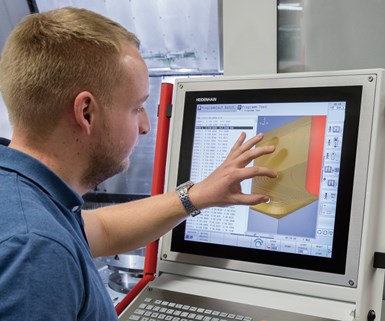

Heidenhain TNC 5X

In a collaborative aimed at enabling five-axis machining for those using Heidenhain TNC controls and Mastercam CAD/CAM software, the companies have introduced a new postprocessor. The Heidenhain TNC 5X Mill postprocessor is the result of coordinated development by the two companies. Those who use Mastercam CAD/CAM software with their iTNC 530, TNC 620 or TNC 640 controls can benefit from this postprocessor, Heidenhain says.

“We are experiencing an increased demand in North America for our newest TNC 640 control for high-precision five-axis machine tools, and we want those customers to know that if they have Mastercam software, we are dedicated to providing ongoing translation updates as needed,” says Gisbert Ledvon, Heidenhain TNC business development manager. Read more.

Kaast V-Mill 600.5X

The V-Mill 600.5X five-axis CNC VMC from Kaast Machine Tools uses a large gantry structure consisting of a base frame, double racks and stable crossbeam to ensure rigidity and cutting performance, the company says. This model also features cooled ballscrews combined with high-quality linear roller guides and a high-speed spindle with ceramic bearings. The 600-mm (23") worktable diameter can support up to 400 kg (880 lbs). Read more.

Kitamura MedCenter5AX

Kitamura Machinery’s compact MedCenter5AX vertical machining center is designed for high-precision, accurate and fast machining of complex, multi-sided parts in one setup. The machine employs a tilting A axis (±120 degrees) and a rotary C axis (360 degrees) with 0.001-degree minimum indexing control. According to the company, machining complicated parts like orthopedic implants or aerospace parts can be completed in one operation, reducing overall machining time. Maximum workpiece size is 220 mm in diameter by 175 mm in height (8.7" × 6.9"), with a maximum table load capacity of 20 kg (44 lbs). The direct-driven fourth- and fifth-axis rotary tables provide smooth simultaneous five-axis movement. Read more.

Milltronics VM250IL-5x

Milltronics’ VM250IL-5x five-axis vertical machining center features a trunnion table 255 mm in diameter and XYZ axis travels measuring 550 × 508 × 520 mm. The rotary table offers +40/-120 degrees of A-axis rotation and 360 degrees in the C axis. The machine is equipped with either a 10,000- or 15,000-rpm inline spindle. A 40-station swing-arm automatic toolchanger comes standard.

The machine uses the company’s 9000-series control. It can be programed conversationally, with G code or with a CAM system. The 9000 series is a Windows-based PC control with an Intel Dual Core i5-3610ME processor (64 bit) with 4 GB of memory, 120 GB of disk storage, two USB ports, mid-travel tactile keys and a large 38.1-cm LCD touchscreen. Read more.

Mitsui Seiki HU100-TS

Mitsui Seiki’s HU100-TS tilting-spindle five-axis horizontal machining center is built to machine large and hard workpieces that may be better suited for tilt-spindle processing than trunnion-table operations. The rigid machine’s fixed table and tilting head arrangement facilitates use of shorter, more rigid tooling. These features make the machine effective with tough materials, such as titanium and Inconel, that are commonly machined in aerospace and power generation applications. Read more.

Takumi U800

Takumi USA has introduced the U800 five-axis machine to the U series, which was developed to achieve high performance for die/mold, aerospace and other high-speed applications that require tighter tolerances. The U800’s X-, Y- and Z-axis travels measure 31.5" × 39.4" × 29.5", and the rotary A and C axes are capable of ±120 and 360 degrees of motion, respectively. The high-torque rotary table measures 800 mm. Read more.

Toyoda FH630SX-i

The FH630SX-i horizontal machining center from JTEKT Toyoda Americas is said to achieve complex part machining and multi-surface processing in one setup by combining high torque and simultaneous five-axis machining.

“From the highly rigid platform to the flexible swivel spindle, our newest five-axis addition combines the stability and versatility that shop owners look for and need with complex cutting production,” says Graham Roeder, national product manager. “Combining the FH630SX-i with four-axis machines on a shared RGV system allows shops to increase performance, enhancing autonomous production.” Read more.

Related Content

How to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.

Read MoreChoosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

Read MoreThreading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreRead Next

High-End Watchmaker Eliminates Offshoring with Five-Axis Machining Center

Instead of shipping small components from overseas, a watchmaker was able to accommodate increased demand by purchasing a used five-axis machining center.

Read MoreBuying a Five-Axis: Selecting the Right Machine

Horizontal or vertical? Trunnion or swivel head? What’s the effective difference between different configurations of five-axis machining centers?

Read MoreFor Large-Part Machining, Five-Axis Capabilities Prove Essential to Staying Competitive

Metalcraft of Mayville’s old milling machine for large parts failed just when the company began seeing increased pressure to take on projects requiring more flexibility and capabilities. Two five-axis HMCs from Toyoda helped the company stay in step with the trend.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)