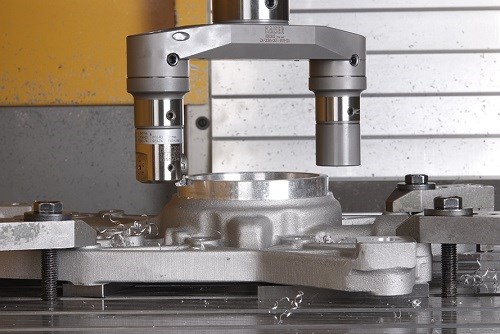

OD Turning on a Machining Center

A tool like the one seen here can make it possible to machine precise cylindrical features of an otherwise odd-shaped part to a fine finish without resorting to a lathe.

You probably didn’t know how effective your machining center could be at OD turning. A tool like the one seen here can make it possible to machine precise cylindrical features of an otherwise odd-shaped part without resorting to a lathe, and doing so in a way that achieves finishes superior to what circular milling can achieve. The tool shown here is supplied by Big Kaiser, which prepared this article on the various tooling types that might be used for OD turning on a machining center.

Related Content

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

Heavy Engineering: The Complex Logistics of Moving Large Machine Tools

One of our fascinations with large-format machine tools has little to do with their capabilities, but everything to do with the logistics involved with getting them up and running. Here’s how one of the world’s oldest builders of giant machine tools tackles the challenge.

-

Positioned to Prevail: Designing Processes Around People

Stecker Machine Company shows that getting the most value from employees means valuing your employees.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)