Preventive Maintenance Via iPad

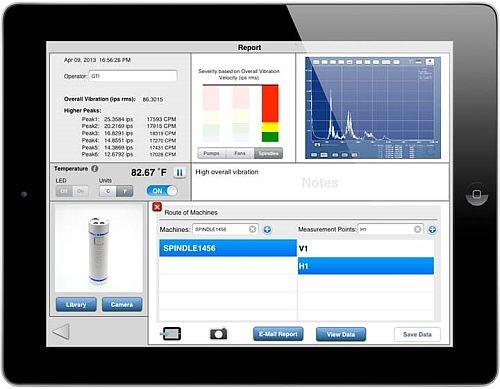

GTI Spindle Technology’s VibePro system enables users to monitor vibrations, temperature, velocity and other critical machine information.

Users of GTI’s VibePro system can monitor, record and analyze data directly on iPad devices.

Headquartered in Manchester, New Hampshire, GTI Spindle Technology provides spindle products, repairs and services for a range of industries including aerospace, defense, medical and more. The company, however, doesn’t just fix broken spindles or sell new ones—it hopes to help shops avoid broken equipment altogether with its VibePro preventive maintenance system that operates through the iPad and iPad Mini. VibePro 6, the most recent iteration, was released in November and is optimized for use with iOS 7 and Apple’s new iPad Air.

The system combines iPad hardware with GTI’s software and various accessories to monitor and analyze indicators including vibrations, balance and more. For example, the Bluetooth-enabled Node Therma sensor records temperatures ranging from -94°F to +716°F within its 15-foot measuring zone, and sends the data wirelessly to the iPad for analysis. Users can view machine data on the iPad itself, or access the information in the cloud via a free web app.

Visit GTI’s website or check out the VibePro 6 Overview video on YouTube for more on this system.

Related Content

-

Understanding CNC Machine Accuracy and Repeatability

Properly evaluating machine tool capability requires understanding how the both user and the builder can influence precision.

-

6 Steps to Take Before Creating a CNC Program

Any time saved by skipping preparation for programming can be easily lost when the program makes it to the machine. Follow these steps to ensure success.

-

Swiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)