Quickly Give Live Tools Coolant-Through Capability

This retrofit system enables users to quickly and easily add through-tool coolant delivery on their live tooling.

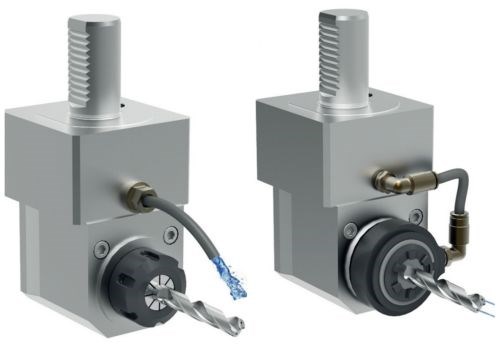

The Recool system from Rego-Fix enables users to quickly replace the conventional spray-pipe coolant delivery system on their live tooling (left) to through-tool coolant delivery (right).

Through-tool coolant delivery is more effective at getting coolant to a tool’s cutting edge than spray pipes or nozzles. Knowing this, Rego-Fix has developed a retrofit through-tool coolant delivery system for live tooling on CNC lathes that is said to install in minutes.

The animation shown here demonstrates how simple it is to install this affordable system. Each Recool kit contains a special clamping nut with outer ring, a coolant pipe and a few fittings. The standard kit achieves maximum speed and pressure of 6,000 rpm and 300 psi, respectively, although higher speeds and coolant pressures are available upon request.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Best Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

-

All-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

.jpg;width=70;height=70;mode=crop)