Real-Time Hob Monitoring

By obtaining the optimal signature for a hobbing operation, this continuous tool monitoring system protects hobs from unnecessary wear, and even failure.

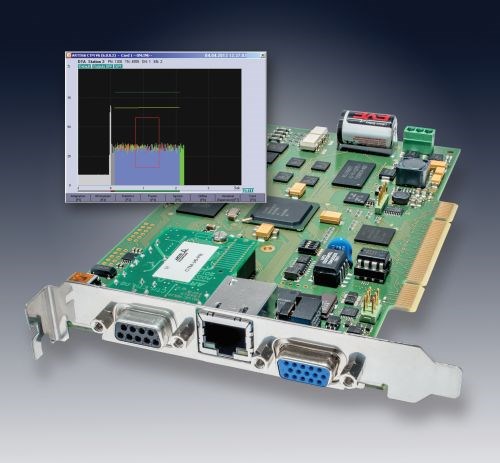

Artis couples multiple sensor inputs with software specifically designed to detect anomalies produced by worn and/or damaged tools in wet and dry cylindrical gear hobbing applications (photo: Liebherr-Verzahntechnik).

Working in conjunction with a major transmission builder, Artis Systems—a Marposs company—has developed a hob-specific continuous tool monitoring system that maximizes output and tool life simultaneously. The CTM system monitors spindle vibration, power consumption and several other parameters to create an exact signature of each cutting operation. It then generates an acceptable tolerance band on each side of the signature. Subsequent operations are compared with the master signature to ensure that the monitored parameters fall within the tolerance band. Hobbing tools may be resharpened as many as 15 times, so this capability is critical in a successful process monitoring solution since an optimum process signature for a resharpened tool can be calculated without remastering the tool, eliminating a major cause of hobbing machine downtime.

Read an article about this real-time tool monitoring system in Gear Production, the supplement to Modern Machine Shop, and watch a video of the Artis CTM system here.

The Artis CTM V6 is the latest generation of the company’s tool, machine and process monitoring solution.

.png;maxWidth=300;quality=90)