Secrets to the Art of Hand Scraping

Hand scraping of mating surfaces on a machine tool enables the surfaces to be flatter, more accurately aligned, longer wearing and freer to glide across one another. No automated or mechanical operation can match these benefits. Machine builder Okuma explains how this seeming paradox is true.

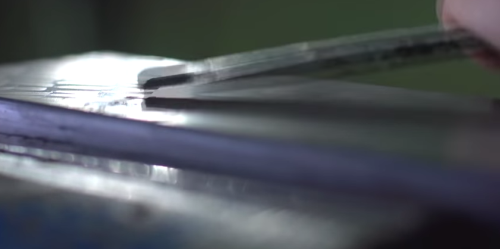

Watch this video for a demo of the hand scraping process, and find a link below to a white paper on the topic.

Hand scraping of mating surfaces on a machine tool enables the surfaces to be flatter, more accurately aligned, longer wearing and freer to glide across one another. No automated or mechanical operation can match these benefits. Machine builder Okuma has issued a white paper detailing the benefits of hand scraping, at technique it applies to all of its machines.

The company contends that hand scraping maintains high levels of CNC machining accuracy and reduces wear and tear, resulting in a long, stable and productive life for the machine. This manual process ensures that tight tolerances are consistently maintained and that precision CNC machining performance is sustained for years, therefore yielding the lowest cost-per-part, the company says.

In a nutshell, the hand-scraping difference accounts for four main benefits.

- Accuracy - Scraping is done to align components within millionths of an inch, allowing for consistently-held, tight tolerances.

- Flatness - Contact points prevent rocking, add balance when tightening, and allow for true flatness in parts.

- Oil Pockets - Oil on the surface allows gliding motion.

- Appearance - The finishing touch of scraping is aesthetic. Parts are “design scraped” to achieve an attractive textured finish.

To download a copy of the white paper, click here.

Related Content

-

Grinding Wheel Safety: Respect The Maximum Speed

One potential source of serious injury in grinding comes from an oversight that is easy to make: operating the wheel in an over-speed condition.

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

-

Understanding Swiss-Type Machining

Once seen as a specialty machine tool, the CNC Swiss-type is increasingly being used in shops that are full of more conventional CNC machines. For the newcomer to Swiss-type machining, here is what the learning curve is like.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)