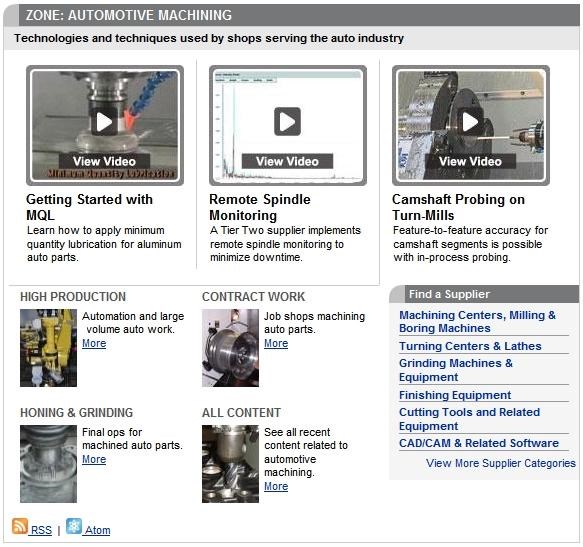

See the New Automotive Machining Zone on MMS Online

Visit mmsonline.com/automotive.

Visit mmsonline.com/automotive.

The landscape of automotive production in America continues to evolve. Today’s ever-changing market demands require automotive contract shops, Tier One and Two suppliers as well as OEMs to be more efficient and flexible than ever before. That’s why we’ve created the new Automotive Machining Zone on MMS Online, which includes many articles and videos focused on effective machining of automotive components.

Some of the videos included in this Zone are referenced in the first three feature stories that appeared in our October issue. The first article, which details how a Ford transmission plant has implemented minimum quantity lubrication (MQL), spotlights a video that explains how shops might apply MQL effectively.

The second article pushes to a video that further explains the remote spindle monitoring technology that a Tier Two automotive shop has adopted to minimize machine downtime due to unforeseen spindle problems.

The third article briefly touches on four videos recently added to coincide with the launch of this new Zone. They reveal:

• the importance of probing when machining large diesel engine camshaft sections on turn-mill machines;

• how Swiss-type lathes, commonly used for long parts, also offer advantages for short, complex parts such as airbag components;

• the advantages of vertical grinding of camshafts with dual, opposed grinding wheels; and

• how two-spindle, five-axis machines can effectively mill and turn two turbocharger housings simultaneously.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)