Control Technology Provider Demonstrates How CNC Advances Factory Digitalization

How users and builders of machine tools can benefit from factory digitalization and integration is the main theme of the Siemens booth at EMO 2017. Highlights include enhancements to the company’s Sinumerik CNC software as well as the introduction of MindSphere, a cloud-based platform for hosting applications that enable manufacturing companies to more fully digitalize their operations.

It is becoming increasingly difficult—and inadequate—to evaluate developments in CNC technology outside of a larger scenario. This is a scenario in which smart, connected devices and machines share data and interact in order to speed production and improve quality. Terms such as Industry 4.0, Industrial Internet of Things (IIoT), and fourth industrial revolution are often used to point to this concept of factory digitalization and integration. In this context, the CNC has a key role beyond driving machine tool axes to execute a part program prepared by CAM software. The CNC is a hub around which and from which vital data streams are flowing.

How the CNC fits into the comprehensive sweep of “digitalized” manufacturing can be seen in the Siemens booth at EMO 2017 this October in Hannover, Germany. At this show, Siemens will demonstrate how machine tool users and machine tool builders can benefit from digitalization within the scope of the company's overarching "Digital Enterprise" concept. Highlights of the innovations to be introduced at EMO include enhancements to the company’s Sinumerik CNC software, as well as the introduction of MindSphere, Siemens’ cloud-based platform for hosting applications that enable manufacturing companies to more fully digitalize their operations.

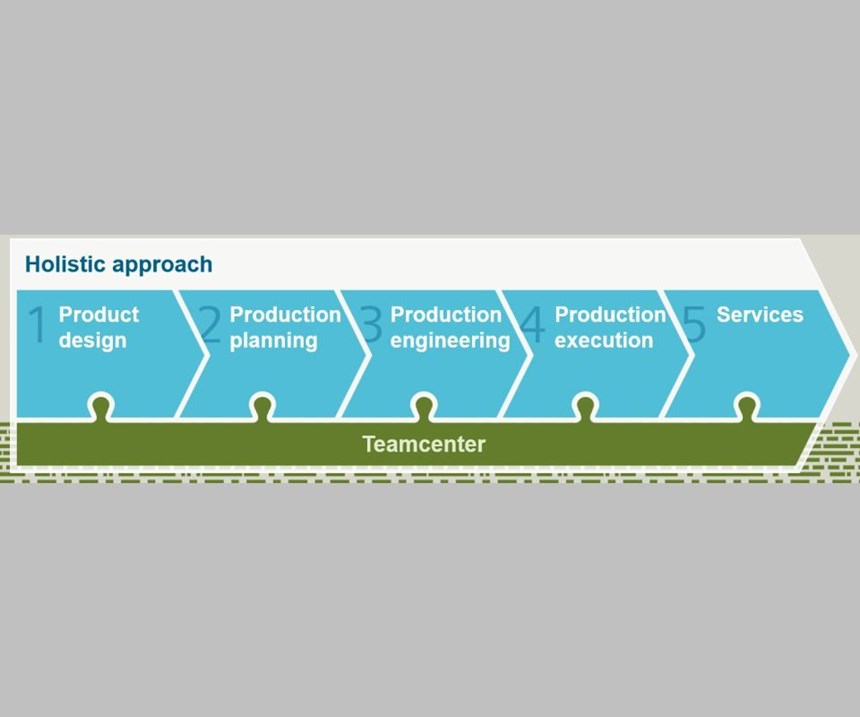

In Siemens’ vision of the digital factory, these operations cover the major steps in manufacturing:

- Initial product design;

- Production planning;

- Production engineering;

- Production execution; and

- Managing services related to the product’s lifecycle under the customer’s ownership.

All of these steps are included in Siemens’ digital enterprise product offerings. For this reason, Siemens calls this a holistic approach to integrating and digitalizing a company’s entire value chain, and it is the underlying theme of these EMO presentations.

Because each of the major steps is largely performed with the help of computer software applications, sharing information and working collaboratively requires a system such as Teamcenter in which a digital twin, or virtual-data model, can be created and handed off seamlessly from task to task. Teamcenter is Siemens’ portfolio of digital product lifestyle solutions. At EMO, Siemens is presenting at least one new development in each of the five basic steps to enhance that step, and in turn, benefit the entire value chain.

For machine tool users, advances introduced in the production-execution step include a new release of Sinumerik CNC software. This release (version 4.8) adds compensation for unwanted axis-nodding movements and protection against machine, tool and workpiece collisions. Nodding compensation is used to adjust for dynamic position deviations in one or more linear axes caused by acceleration processes. Nodding compensation counteracts the dominant position deviation by initiating a corrective movement in the relevant machine axis, thus enabling improved machining quality simultaneously with higher jerk and acceleration values, the company says. Nodding compensation can be used in conjunction with milling, multitasking, tapping, laser machining or waterjet machining.

The new collision-protection feature covers two versions. The Eco version is designed to prevent collisions between the machine body and its own components within the work area. To achieve this effect in real time, the assemblies that need protection are calculated as simple geometric bodies created and visualized in 3D at the control interface. The Advanced variant includes full machine, tool and workpiece protection. The software provided by the Sinumerik product partner ModuleWorks runs via an interface integrated on an external PC, and works together with the CNC in real time to ensure that the machine, tool and workpiece can be continuously monitored and are dynamically protected during the machining process.

In addition, the Sinumerik Operate user interface has been enhanced to enable machine tool builders to develop customized side screens to show axis loads, alarms or tooling information along with other content of their own choosing, if desired. The side-screen option is available on a new line of widescreen monitors for Sinumerik CNCs. The design of these monitor screens eliminates separate function buttons, which have been replaced by a touch-sensitive screen surface with the capability of showing and hiding a side screen.

Data generated by the CNC and transmitted to a network will take on greater importance and usefulness, thanks to new software applications, the company says. Siemens-developed apps such as Analyze MyPerformance and Analyze MyCondition provide reports about machine tool output and operating status for shopfloor viewing at the CNC. Additional apps can be hosted on MindSphere, Siemens’ cloud-based operating system, which has an open-source architecture. MindSphere, the company says, provides a platform and infrastructure for its own apps, as well as for apps developed by third parties, which can also access, analyze and report on data streaming from connected CNCs.

For example, Siemens has created Manage MyMachines, an app within MindSphere that enables shop managers to have a cloud-based overview of critical machine data and current operating status of all connected machines. The open nature of MindSphere is designed to encourage development of apps by third-party partners, using MindSphere as the platform. MindApps is the name given to this growing collection of manufacturing execution apps.

To facilitate connecting CNCs and other equipment for data streaming to MindSphere, Siemens has developed MindConnect. This utility interfaces directly with Sinumerik CNCs, or indirectly with controls from other CNC suppliers using an add-on connector box. MindConnect is said to provide secure and encrypted data communication.

At EMO, Siemens is predicting that as many as 200 machine tools at the show will be connected to MindSphere as a demonstration of its potential for manufacturing digitalization.

Related Content

Give Job Shop Digitalization a Customer Focus

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

Read MoreHow to Grow the Business with Real-Time Job Status Data

ERP systems that focus on making data more accessible can improve communication within a shop, reducing wasteful errors and improving capacity.

Read MoreDiving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)