The Evolution of the Retention Pin

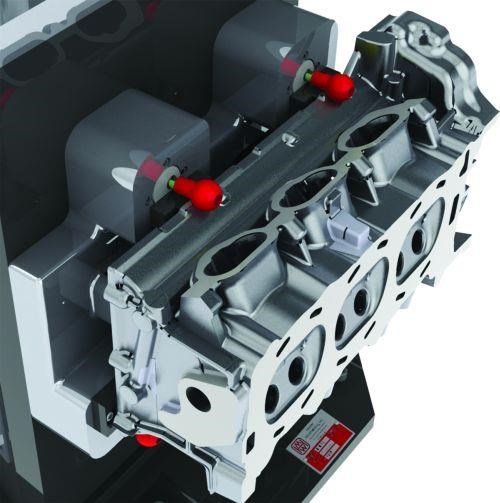

A new retention pin design enables the spring-loaded workholding devices to do more than simply ease part loading. They can clamp parts, too.

Over the years, spring-loaded retention pin designs have evolved. Traditionally, they have helped users locate a part on a fixture and hold it in place before actuating swing or link clamps that secure the part for machining. However, this new version from Master Workholding includes a hydraulic circuit enabling the devices to function as clamps, too.

Related Content

-

Fixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

-

When To Use A Collet Chuck

Don't assume the standard chuck is the right workholding for every lathe application.

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

.jpg;width=70;height=70;mode=crop)