Turn-Mill Machines: Software is Significant

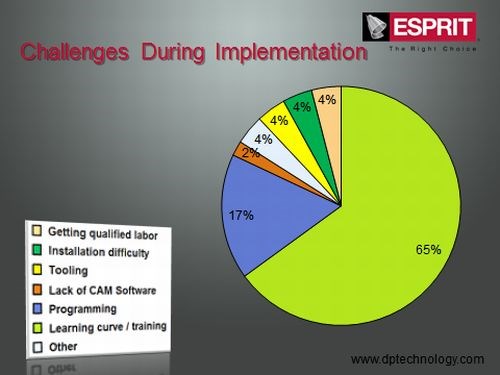

This chart shows the results of DP Technology's study about the challenges related to turn-mill implementation.

This chart shows the results of DP Technology's study about the challenges related to turn-mill implementation.

Manufacturers keep embracing “multitasking” or “turn-mill” machines in order to achieve single-setup machining of short runs of parts. However, when looking to such sophisticated machinery, shops also need to be looking at software. That was the conclusion of none other than a maker of turn-mill machine tools, after it recently surveyed the reasons for implementation challenges with these machines.

The pie chart above was supplied by CAM software developer DP Technology, summarizing the results of the machine tool maker’s study. As the chart shows, 2 percent of implementation struggles have to do with the lack of appropriate CAM software, but another 17 percent have to do with problems related to CAM.

Then there is the largest piece, 65 percent, which relates to the learning curve and training time. Because a user’s main interface with the machine is likely to be the CAM software, it stands to reason that some portion of this time actually relates to the difficulty of becoming proficient with the software. Therefore, DP’s interpretation is that somewhere between 20 and 85 percent of the potential problems with new turn-mill machines can be attributed to CAM. To avoid implementation difficulties, a shop should make finding the right CAM software an early priority during the process of evaluating one of these machines.

DP recently delivered a webinar on CAM software for turn-mill machines. View it here. For a lot more information on turn-mill machines in general, click here.

.jpg;width=70;height=70;mode=crop)