Integrated Waterjet Expands Laser Cutting Potential

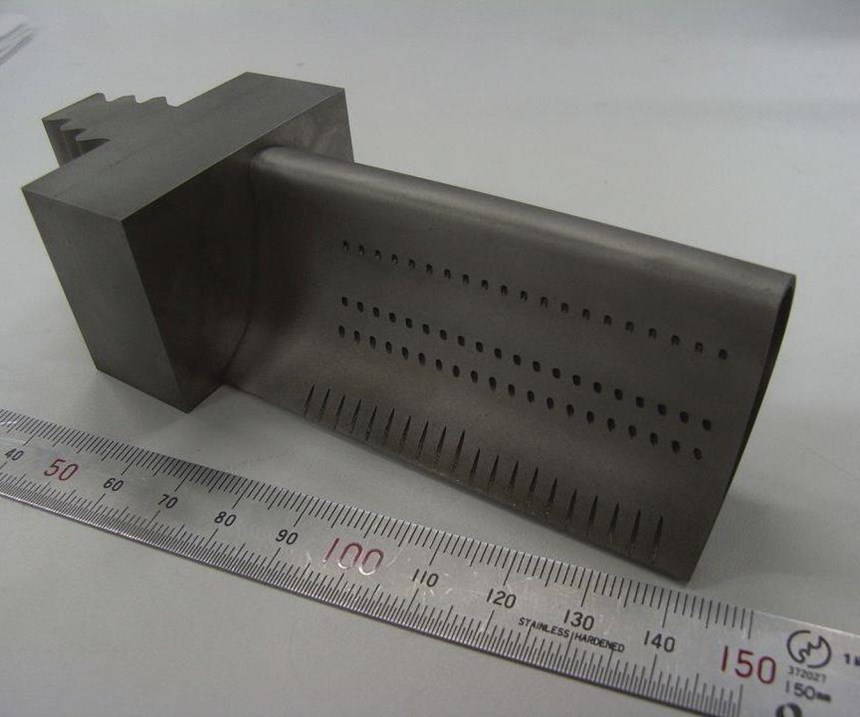

Designed for small, intricate features like turbine blade cooling holes, technology that fuses water and light virtually eliminates the traditional drawbacks of laser cutting without compromising the benefits.

Just add water.

According to a report recently published by General Electric, that’s the ticket to making laser machining a viable process for producing the cooling holes that pepper the surfaces of turbine blades for both gas and industrial applications. This unique variety of laser cutting has reportedly helped GE save hours of production time on every part, and now, the technology’s Swiss developer and its North American partners hope to spread the gains to other turbine blade manufacturers as well. After all, they say it not only offers all the speed and precision for which laser cutting has long been renowned, but also eliminates the traditional drawbacks: namely, heat affecting the material structure and machined sludge adhering to the surface.

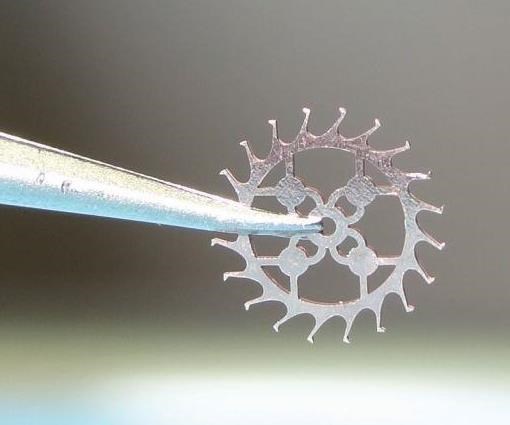

However, these aren’t the only advantages, and applications aren’t limited to drilling cooling holes. According to the aforementioned article, which appeared in the company’s GE Reports publication (gereports.com), GE is also leveraging these lasers to produce other turbine components from new, heat-resistant (and thus difficult-to-machine) materials. Other manufacturers tasked with creating minute, intricate features stand to gain as well. Scalpels, needles and other medical devices; automobile fuel injection nozzles and spark plugs; monocrystalline and polycrystalline diamond (PCD) cutting tools—these are just a few other documented examples of work for which this particular variety of laser cutting has proven to be a viable alternative to processes ranging from milling to etching to EDM. In addition to the kind of cool, clean material removal going on at GE, the technology’s developer says discrete parts manufacturers can benefit from the technology’s capacity for virtually taper-free cutting throughout the entire depth range without worrying about focus.

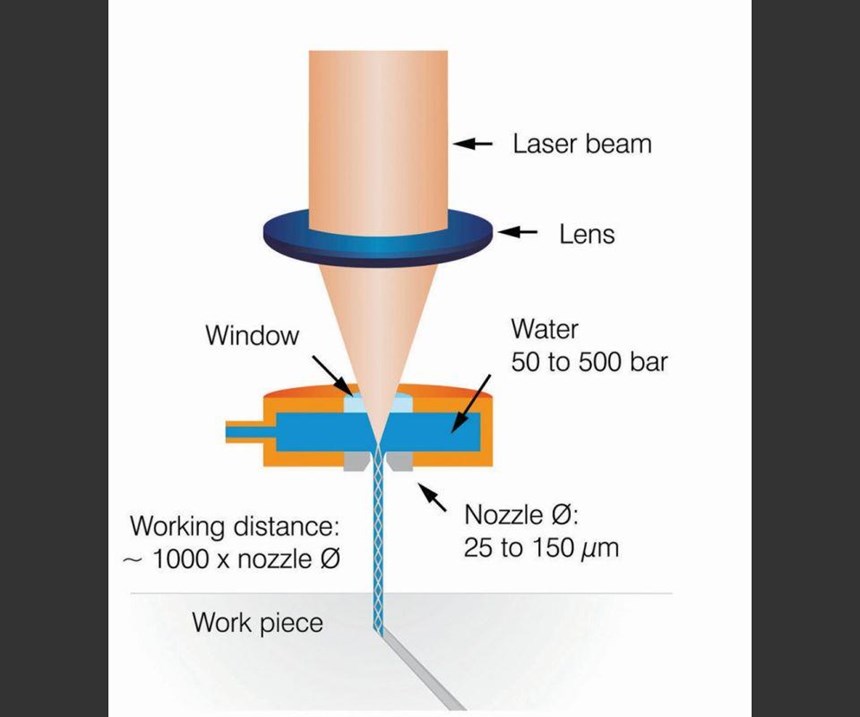

How is all this possible? Again, through the presence of that most essential of essential elements: water. More specifically, through a compact, pressurized stream of water that completely encases the laser beam, thus serving as a guide, a cooling medium and a cleaning agent all at once.

Expanding Reach

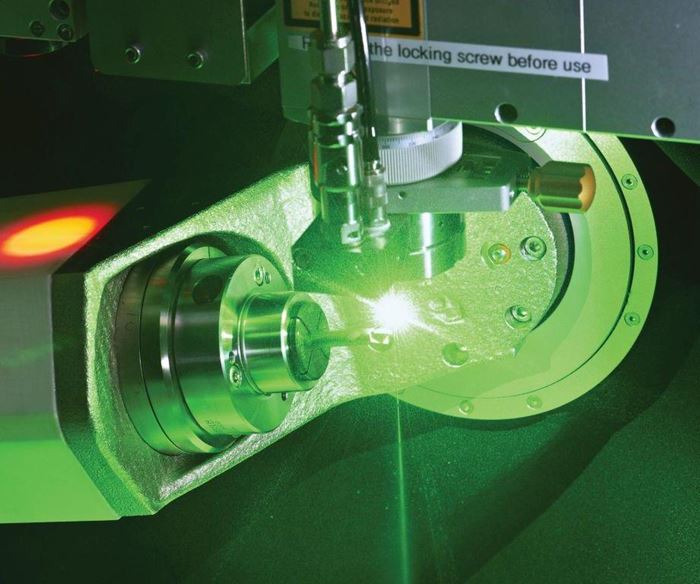

After developing what’s now called Laser MicroJet (LMJ) at the Federal Institute of Technology (EPFL) in Lausanne, Switzerland, PhD student Bernold Richerzhagen founded Synova in 1997 to bring the newly patented technology to industrial manufacturers. During the next 20-odd years, Synova penetrated markets ranging from diamond and gem cutting to semiconductors and electronics, relying on machine-building partners to provide the right industry-specific platforms for LMJ. Although the company has maintained a U.S. office near its small customer base in Silicon Valley since 2003, providing the sales, service and support infrastructure needed to push LMJ on a wider scale required accelerating the pace of collaboration with one key partner, says Jacque Coderre, U.S. business manager.

That partner is machine tool builder Makino, and the acceleration was thanks to the two companies’ recent work with GE on applying LMJ to turbine blade cooling hole production. This work resulted in the development of the MCS line of LMJ machining centers, and, in May of this year, an exclusive sales, distribution and after-sales support agreement with Single Source Technologies (SST), an arm of Makino that provides engineering, field service and sales of products that complement the builder’s own milling and EDM lines. Two sizes are available: the three-axis MCS 300, and the larger, five-axis MCS 500, which is designed specifically for 3D operations like those being conducted at GE. Synova’s LCS line, a non-Makino system for precision machining of smaller metal and hard-material parts than those suited for an MCS, is also available through SST (the largest LCS, the LCS 300, offers a work envelope of 300 by 300 mm, whereas the MCS 500 offers 500 by 400 mm).

In both lines, the cutting action falls to diode-pumped, solid-state, neodymium-doped yttrium aluminum garnet (Nd:YAG) lasers with pulse durations measured in nanoseconds, average power of 50-200 watts, and wavelengths of 532 Nm (certain LCS models also offer 1064 Nm). Kerf widths closely match nozzle diameter, and accuracy and repeatability are measured in microns. Beams are encased in pure, deionized and filtered water projected at low pressure to limit the risk of adverse impacts from the water stream. Acting very much like a fiber-optic cable, this stream ensures that machining is cool, clean and true.

Cool, Clean and True

Essentially “trapping” a laser beam within a stream of water is possible because of the principle of total internal reflection. This phenomenon occurs when a wave of energy (in this case, a laser beam) completely reflects off a boundary with a less-dense medium (in this case, the boundary between water and air) so that no energy passes through. As depicted in the diagram on the previous page, LMJ leverages this principle to reflect the beam back and forth off the interior wall of the water stream, thus forcing it along a straight, narrow path from nozzle to workpiece.

If that principle is straightforward, the engineering is anything but. The machine platforms feature various, built-in subsystems for treating and safely accommodating the water. As for the laser head itself, the beam must approach the boundary at certain angles to reflect back rather than pass through it, to name one challenge. The jet of water also must be highly stable, with consistent boundaries, to prevent the beam from escaping. To that end, one of Synova’s various international patents involves the use of gas-enveloped liquid jets to prevent stream turbulence. Nozzles, constructed of sapphire or diamond for durability, are specially shaped to ensure proper interaction of gas and water, among other reasons. Optimizing the shape of the water chamber also took years of experimentation, Mr. Coderre says.

Although Synova is understandably tight-lipped about these and other critical design features, literature from the company describes how this unique technology differs from conventional laser machining in three fundamental ways:

- No taper. LMJ system nozzles are available in sizes ranging from 25 to 120 microns in diameter, with the low-pressure water stream measuring 15 percent smaller than that. Leveraging the power of the continually reflecting beam within, the stream becomes, in essence, a perfectly cylindrical blade, one that leaves perfectly straight walls in its wake. Absent a guiding stream of water, laser beams are naturally cone-shaped, narrowing from the source to a specific focal point before flaring out again. As a result, cutting depth and focal point position must be tightly controlled to avoid unwanted taper in the cut. The addition of water eliminates the need for this attention. According to Synova documentation, the waterjet can project to a distance as far as 1,000 times the nozzle diameter before it—and the laser light within—begins to break apart (the MCS line boasts a maximum working range of 100 mm).

- No heat-affected zone. Although lasers can be difficult to beat in terms of raw speed and precision, only certain applications lend themselves to a process that works by essentially melting material away. Generally, the nature of laser ablation precludes its use on any workpiece that might be adversely affected by micro-cracking, deformation and other conditions that might occur within the heat-affected zone around the cutting area. In an LMJ system, the hair-thin stream of water surrounding the beam absorbs this heat in the micro-second gaps between laser pulses.

- No material deposition. The jet of water removes more than just heat from the cutting zone. It also carries away ablated waste material and any other contaminants that might otherwise adhere to the workpiece as slag. The result is cleaner cutting and the potential elimination of deburring and other downstream operations.

The combination of these three advantages provides LMJ with the versatility to cut intricate features into virtually any material except glass, wood, paper, textiles and clear plastic. This makes the process a viable alternative to not just dry laser cutting, but a host of other processes as well, Mr. Coderre says.

A Complement and Alternative

Since the 2001 introduction of the LCS line, which expanded the company’s focus to include metal and other hard materials, Synova has documented multiple examples of LMJ replacing other processes at customer facilities around the world. According to the company, it’s often proven faster than milling micro-parts—assuming the material is soft enough that milling would even be an option—and it eliminates concerns about burrs or broken tools as well. It can be much faster than EDM, which can create micro-cracks in certain surfaces, necessitates regular replacement of electrodes and/or wire, and works only on conductive materials. It has proven more flexible than electroforming or stamping, and capable of creating smaller dimensions than the latter. Stainless steel, aluminum, copper beryllium, nickel titanium, cubic boron nitride—LMJ is a potential fit for a wide variety of applications, particularly in the medical, cutting tool and automotive markets.

However, the recent unveiling of the MCS series and agreement with SST reveals the extent of the opportunity Synova sees in the industrial turbine market, particularly with the added technology and expertise of a partner like Makino. Based on concepts proven out at GE, SST is now marketing what it calls a “hybrid cell,” consisting of an MCS 500 and a Makino EDBV EDM drill, that’s dedicated specifically to drilling cooling holes in cast blade and vane components with hollow interiors. “Coupling (LMJ) with our EDBV series of EDMs enables users to drill a complete blade with optimum output, including the drilling of non-line-of-sight holes,” says Mark Logan, director of Makino\SST.

These turbine blades and vanes are commonly coated with a ceramic thermal barrier to help withstand intense heat, he explains. The problem is, these coatings aren’t conductive, and EDM works only with conductive materials. As a result, manufacturers commonly EDM-drill the holes before applying the coating. Complicating matters is the fact that cooling holes are becoming more complex these days. Designers increasingly employ diffuser holes with tapered, square or otherwise non-round openings that aren’t always centered to the outer diffuser shape. With EDM alone, manufacturers often opt to machine these features larger than specifications in order to accommodate the thickness of the coating, some of which might need to be removed from the features by hand afterwards. An automated, hybrid cell with a scheme for transferring data between machines simplifies this process. Initial coating penetration and machining of the diffuser shape can be performed by LMJ while leaving the bulk of the hole to the EDM drill.

At least, that’s usually the case. If a hole is shallow enough, LMJ is perfectly capable of machining the entire geometry, and it might do so faster than the EDM drill. At a certain depth, however, EDM becomes faster, and is the only option at the point where the water stream begins to break up. EDBV machines offer other advantages as well. For instance, their electrical generators feature dynamic feedback circuits that sense the position of the tube electrode and increase feed as-needed to minimize “air cutting,” particularly at high engagement angles. The machines also sense when the electrode breaks through to the inner cavity within one second or 0.04 inch of depth to maintain speed while preventing back-striking, which can disrupt airflow. Makino’s specialized bending guides also facilitate machining non-line-of-sight turbine engine hole features, says Brian Pfluger, EDM product manager.

Suffice it to say that both LMJ and EDM drilling have their place in these applications, and it’s up to the manufacturer to determine which is best for any given job. Combining both in one cell enables the two processes to balance the workload, thus pushing quality and productivity to levels beyond what would be possible with either system in isolation. Meanwhile, according to GE Reports, that company is already leveraging LMJ machines to cut discrete turbine parts from ceramic matrix composites. If GE’s experience is any indication, other manufacturers, too, can benefit from the addition of LMJ to the proverbial machining toolbox, both as a complement and alternative to other processes.

Related Content

10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

Read MoreVolumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

Read MoreChoosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

Read MoreChoosing The Right Grinding Wheel

Understanding grinding wheel fundamentals will help you choose the right wheel for the job.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)