On Power, Torque, Speed and Hogging Titanium

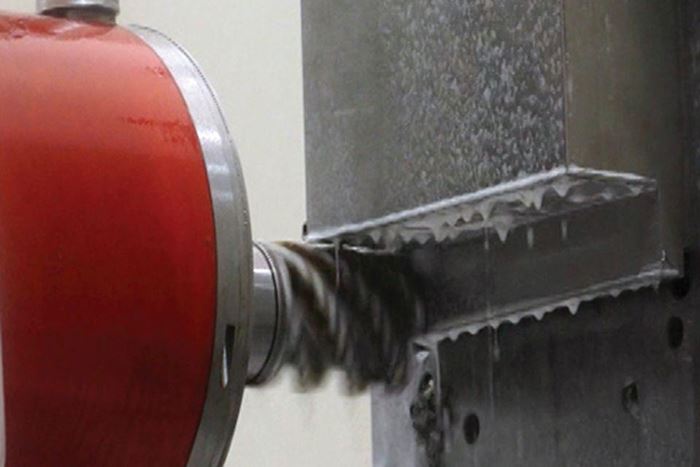

The T-Rex spindle from Fives Giddings & Lewis is designed for high-torque and low-speed cutting critical for hogging titanium.

Although horsepower can provide a good indication of a machine tool’s potential for serious metal removal, it’s not always enough by itself. Particularly when applications involve heat-resistant materials like titanium, Inconel and age-hardened stainless alloys like Carpenter 465, low-end torque and overall system rigidity also become critical.

Consider a spindle designed specifically for such materials, the T-Rex from Fives Giddings & Lewis (G&L). Paired with one of the builder’s HMC 1600 machines, this spindle plowed through 6AL-4V at a rate of 33.1 in.3/min in a recent test cut. This success was thanks largely to raw power—80.5 hp (60 kW), to be exact. However, another spindle with the same or an even greater horsepower rating won’t necessarily perform the same way. That’s because horsepower matters only to the extent that it can actually be applied to the cut, says Pete Beyer, director of product strategy and development at G&L.

The chief difficulty with applying all available power in materials like titanium is a strict speed limit, he explains. Because of poor thermal conductivity, the heat generated by the metalcutting process tends to spread into the tool rather than evacuating with the chips. The faster the cutter spins, the hotter it gets and the faster it wears, so recommended spindle speeds tend to be slow relative to other commonly machined metals. (For its part, the titanium test cut employed a 3-inch-diameter indexable end mill at 245 rpm.) Given this limitation on speed, torque becomes the only means to achieve the necessary horsepower for efficient material removal. After all, horsepower is proportional to the torque times the speed.

Of course, achieving anything close to 33.1 in.3/min in these materials requires a great deal of horsepower at low speeds, and thus, a great deal of torque. The speed limit isn’t the only reason why. Materials like titanium tend to harden more quickly than most metals under the friction and heat of machining, says Jim Vadnais, product manager for G&L’s line of horizontal boring mills. One common strategy is to take a deeper cut in order to “outrun” this rapid work hardening (hence the 3-inch/76.2-mm axial cutting depth and a 1-inch/25.4-mm radial cutting depth specified for the T-Rex test cut). Of course, the deeper the cut, the greater the torque required to achieve the necessary horsepower for efficient material removal.

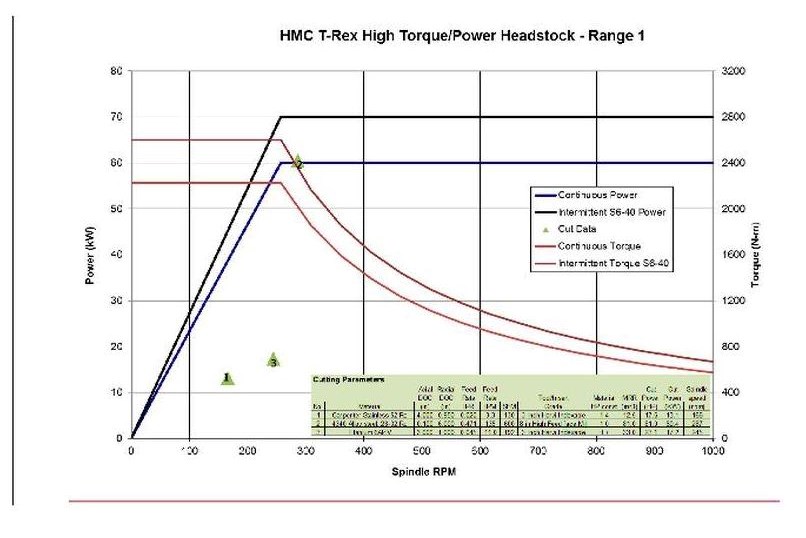

Given these requirements, it is understandable that torque, not horsepower, is the primary focus of G&L’s T-Rex marketing material—specifically, 1,623 foot-pounds (2,200 Nm) of continuous torque. In isolation, however, even a high torque rating doesn’t necessarily paint a full picture of a spindle’s capability, Mr. Beyer and Mr. Vadnais say. That’s because the asynchronous motors that power the T-Rex and most other machine tool spindles can’t output maximum torque throughout the entire range of spindle speeds. Rather, full torque is available only through the base speed (for the T-rex, 260 rpm). After that, overall horsepower remains constant with faster speeds, but torque drops steadily until the spindle reaches maximum speed (5,000 rpm for the T-rex).

What, then, should manufacturers look at to determine a spindle’s true suitability for hogging these difficult materials? Mr. Beyer and Mr. Vadnais say the power curve diagram is a good place to start. In documentation for G&L spindles, this diagram is a line graph that plots torque and horsepower (Y axis) versus spindle speed (X axis), thus revealing how much torque and overall horsepower can be leveraged at any given speed. In its own documentation, the company even overlays the power required for specific cutting conditions (speeds, feeds, depths and so forth) for easier reference, as shown by the triangles in the graph below. (At the titanium test cut’s 245 rpm, for example, the T-Rex can output 75 hp/56 kW for a cut that requires 23 hp/17 kW). Applying the curve is a matter of finding the recommended spindle speed for the application (typically supplied by the cutting tool manufacturer), then adjusting feed rates and/or cutting depths to maximize available power usage. Mr. Beyer and Mr. Vadnais also emphasize the importance of distinguishing between continuous duty ratings and intermittent duty ratings, both for horsepower and torque specifications. (The T-Rex’s 80.5/60 kW total hp and 1,623 foot-pounds/2,000 Nm of torque are both continuous.)

In any case, manufacturers interested in heavy machining of difficult materials like titanium can generally exclude integral and belt-driven motors from consideration. Generally, a gearbox is required to convert motor power to low-end torque, Mr. Beyer and Mr. Vadnais say, adding that the T-Rex features a particularly large motor and gearbox for just that purpose. They add that the spindle’s robust construction is critical to performance as well, particularly its 5.1-inch-diameter (130-mm) spindle bearings. This design feature helps the spindle handle the significant axis thrust required to achieve efficient material removal in hardened metals without creating deflection during X and Y axis moves.

It follows that it’s also necessary to have a machine capable of generating such thrust. G&L’s HMC 1600 horizontal machining center, which was used in the test cut, delivers thrust of 9,500 pounds (42.3 kN). The rigidity of the machine itself is also critical, Mr. Beyer and Mr. Vadnais say. Among other features to that end, this large, 50-taper or HSK 100A-spindle HMC is available with 50-taper or HSK 100A interface; a sturdy, cast iron base; hydrostatic table; and heavy-duty, hardened and ground roller guideways, which are said to provide greater load capacity and operating life.

All in all, machining large amounts of titanium and other heat-resistant materials in a hurry takes a system, one that also includes the right workholding, cutting tools, programming strategies and more. Nonetheless, success begins with a rigid, high-horsepower and high-thrust machining system, as well as a deep understanding of the factors that influence how much of that horsepower the spindle can actually use in a given application.

Related Content

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

Read MoreShop Replaces Two Verticals With One Horizontal

By trading two VMCs in to help finance the purchase of a new HMC, this shop was able to significantly increase production and move to lights-out machining.

Read MoreBest Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

Read MoreHorizontal Turning Center Ready for High Production

Romi Machine Tools’ new GL300 S features high-power torque and feed force and is built with a robust monoblock base for ultimate rigidity and precision.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)