Video: Music by Modulation

M4 Sciences makes a device that uses modulation-assisted machining to prevent chips from binding during deep drilling. Called “TriboMAM,” the system oscillates the drill in and out of the cut 1,000 times per second.

M4 Sciences makes a device that uses modulation-assisted machining to prevent chips from binding during deep drilling. Called “TriboMAM,” the system oscillates the drill in and out of the cut 1,000 times per second. One of its users is this shop: Alphatec Spine.

Previously, a small problem with this system related to confirming that the unit had activated. At full speed, its operation is not audible. How could the operator be sure it was running? This was indeed a small problem, because M4 Sciences implemented a simple solution: Running at a slower, audible frequency immediately at startup enables the unit to make a sound that users can hear.

This video shows the company taking that solution a little farther. Running at a series of frequencies creates an effect that is not only audible, but recognizeable.

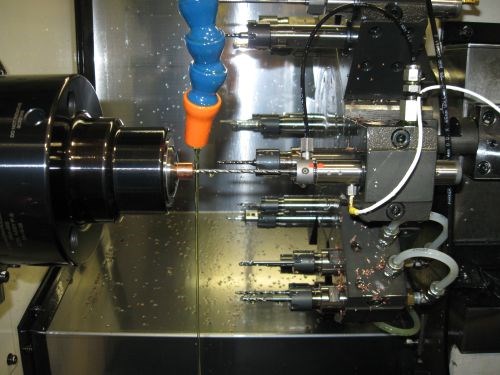

In the video, the TriboMAM unit (making the music) is the cylindrical object in the foreground. The photo below shows the unit in use within a CNC lathe.

Related Content

-

Walter Launches New Solid Carbide Drill

The DC118 Supreme solid carbide drill provides high rigidity against deflection, superior centering accuracy and four margins with corner chamfers.

-

Tungaloy Expands Drill System With Drill Sleeves

Adding drill sleeves to the standard lineup enhances drilling productivity of Swiss-type sliding-head automatic lathes.

-

Walter Offers New Solid-Carbide Taps for Blind-Hole Machining

Walter’s TC388 Supreme and TC389 Supreme feature patent-pending cutting geometries that fully shear off the root of the chip when reversing, thus minimizing torque peaks.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)