Video: The Advantages of Serrated Button Inserts

Although round cutting inserts have a well-deserved reputation for efficiently roughing contoured geometry, they sometimes work best when they’re not perfectly round.

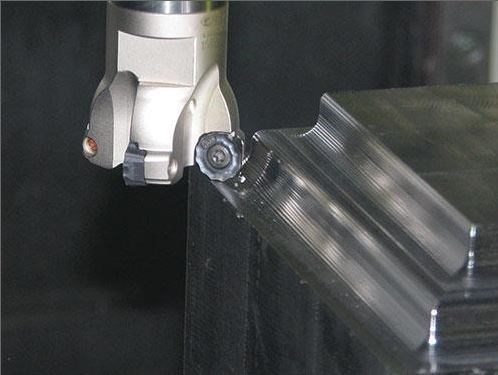

Machinists aren’t likely surprised by the fact that the tool used in the long-reach application depicted in the video above features button-style inserts (courtesy of Ingersoll Cutting Tools, the video showcases the Formmaster R). Look a bit closer, however, and you’ll notice that those double-sided inserts aren’t perfectly round. Rather, the cutting edges are serrated. Employed correctly, a toothed edge can add to the strength and stability that have made button inserts so popular for heavy roughing. This January-issue article provides more information.

Related Content

-

How to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

.png;maxWidth=300;quality=90)