What Does Lean Actually Mean?

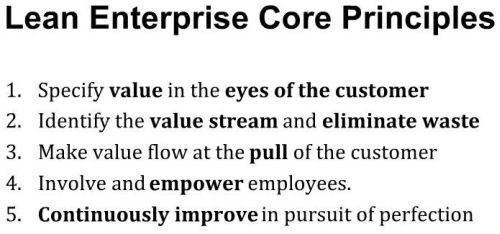

It's important to make sure your employees are on the same page if you are considering a move to lean. Watch this presentation by BlueSwarf CEO Greg Eckerman for an introduction to lean's core principles.

BlueSwarf CEO Greg Eckerman recently created this presentation providing an overview of the purpose and practice of lean. The presentation is valuable not only as an introduction to lean, but also as an aid to ensure that everyone within an organization is thinking about lean the same way. Employee participation is essential to the success of a lean transformation. Eighty percent of the effort in this transformation relates to culture change, Mr. Eckerman says. If your facility is considering a move to lean, consider sharing the link to this presentation with employees.

Related Content

-

What Are the Limits to Make-to-Order Manufacturing?

Automated storage and retrieval system maker Modula produces a product with 2,000 parts and hundreds of variations that has to be completed within a customer’s site. Here is a picture of what is possible in making a product tailored to the customer.

-

10 Lean Manufacturing Ideas for Machine Shops

In addition to the right mix of traditional strategies, a lean manufacturing toolkit can make high-mix, low-volume machining faster, more predictable and less expensive.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)