Where More Flutes Make Sense

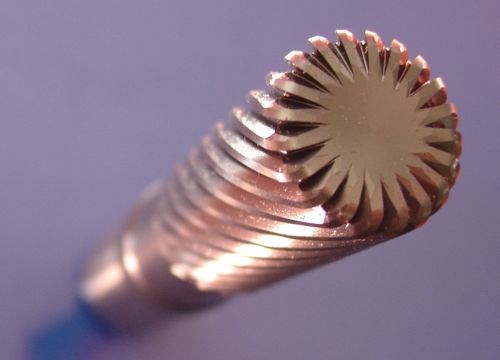

A tool with many flutes can be effective for achieving a productive metal removal rate in titanium, where speed and chip load are constrained.

MAG’s cryogenic machining is an extreme response to the danger of heat in machining titanium, but the company says heat has always been the enemy. The company offers 20-flute end mills for titanium because the large number of flutes offers a way to cut at low surface speed and light depth of cut, but still maintain a high metal removal rate through a high inch-per-minute feed rate. See video of a 20-flute tool.

Related Content

-

Tungaloy Expands Line of Barrel-Shaped End Mills

The new SolidMeister barrel end mills are efficient tools for complex 3D-surfacing operations used in mold making, orthopedic implants and the machining of other freeform surfaces.

-

10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)