With Great Power Comes Great Responsibility

Manufacturing equipment is powerful, and things that are powerful also tend to be dangerous. Has your shop taken the necessary safety precautions?

One idea that’s commonly emphasized by efforts to attract fresh talent to our industry is that the most modern manufacturing facilities are not as dangerous as the factories of yesteryear. That may be true on the whole. However, the fact remains that the equipment MMS readers interact with day-in and day-out tends to be powerful, to say the least. And as we all learned from Spider Man, great power comes with great responsibility. Specifically, the responsibility to ensure people respect that power and stay safe, using standardized, enforceable procedures to that end wherever possible.

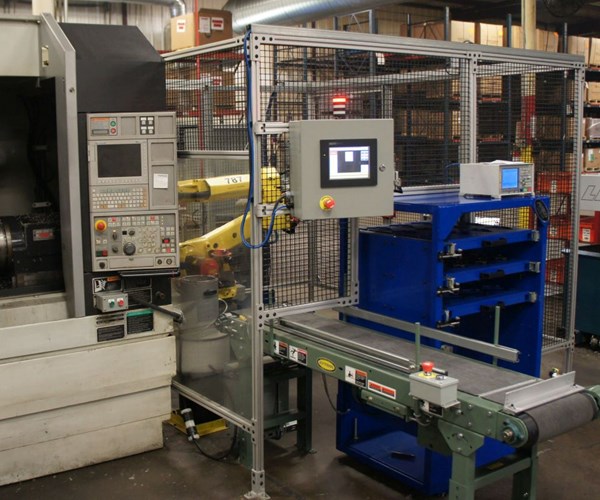

Consider how people interact with the many robots on the floor at Vickers Engineering, an automotive manufacturer in Southwest Michigan (the company’s transition from HMC to VMC cells was the subject of this feature article). As you can see above, these robots are surrounded by cages, and for good reason: When every cent of per-part cost means the difference between success and failure, speed is paramount, and these bots brake for no one, following programmed routines to the letter regardless of who or what may be in the way.

When employees do enter the cage, it’s not a simple matter of opening the door. There’s a lockout/tagout procedure involved. The first step is retrieving a lock and a hasp from a group box located on the exterior of the cage surrounding each cell. The hasp attaches to the interlock mechanism of the door, and the employee’s badge attaches to the hasp via “lockout” holes on the badges. With the lock, badge and hasp in place, the employee removes the key and pockets it, where it remains until the lock is ready to be removed. Under no circumstances is the employee permitted to give the key to someone else or to lose possession of it. Any additional employees that enter the cage must also place their badges and locks on the group hasp and secure the key. Once finished, employees remove their locks and badges and return the locks (locked, with the key inserted) to the group box. The last person to exit removes the group hasp, shuts the cage door and returns the hasp to the box.

A robot transfers a part from machine to dedicated etching station in one of Vickers Engineering’s new cells, which employ VMCs instead of the HMCs that made up the majority of previous cells. This article details strategies for making this transition work.

Although the industry has come a long way when it comes to safety, there’s reason for such involved procedures: Shopfloor work always has been, and likely always will be, inherently dangerous to some extent. One false move can change lives, and although today’s manufacturing equipment is safer and more autonomous than ever before, built-in systems aren’t always enough to prevent that from happening. Safety takes thought and effort, and formal procedures and checklists are arguably even more important these days as companies continue attempts to attract young people to the field—young people who often have zero experience in a manufacturing environment.

For more on this topic, check out this article from MMS sister publication Production Machining. Whether you have robots or not, author Miles Free, a regular PM contributor and director of technology services at the Precision Machined Products Association (PMPA), offers a useful checklist of things to watch out for in your own operation.

Related Content

Modern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

Read MoreBeyond the Machines: How Quality Control Software Is Automating Measurement & Inspection

A high-precision shop producing medical and aerospace parts was about to lose its quality management system. When it found a replacement, it also found a partner that helped the shop bring a new level of automation to its inspection process.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreBuilding an Automation Solution From the Ground Up

IMTS 2022 provides visitors the opportunity to meet with product experts to design automation solutions from scratch.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More