The Swiss Army knife has been around for more than 100 years. It’s an invaluable collection of tools and accessories that can get you by in an emergency. The tools may not be as good as their single-purpose counterparts, but when you’ve got that special bottle of wine out in the countryside and there isn’t a corkscrew around for 15 miles, that odd little one stored in your little Swiss Army knife is worth its weight in gold.

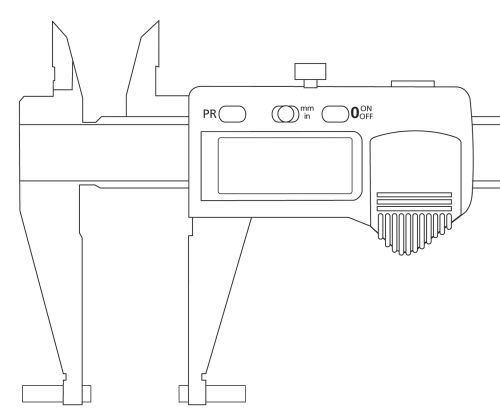

The same can be said of the universal digital caliper. This caliper is more than a standard caliper, as it has the ability to accessorize itself with a host of special contacts to expand its measuring capability.

The four basic measurements a caliper can make include: outside, inside, depth and step measurements. These can be measured with just about any Vernier, dial or digital caliper—kind of like a run-of-the-mill pocket knife. However, when the caliper is digital, you can take these measurements one step further and do some of the arithmetic required for compound measurements.

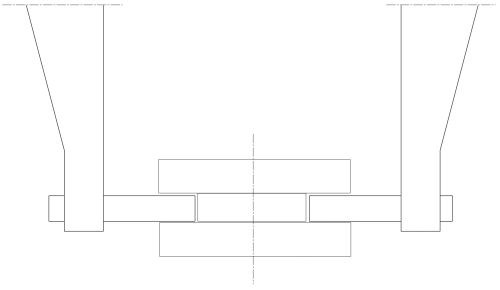

By using this feature and technique on adjacent bores, for example, it’s possible to measure one bore, zero the gage on this bore, and—using the same inside-diameter jaws—measure the distance between the far surfaces of the two adjacent bores. The caliper can then calculate the center distance between the two bores.

Need to make a shaft or pin to fit an existing bore? Or, are you boring a cylinder to fit a piston? You can use your electronic caliper to read the size difference directly. Use the inside jaws to measure the diameter of the bore. Before you remove the caliper from the bore, press the button to zero the caliper. Now use the outside jaws to measure the shaft. A positive reading (no minus sign displayed) shows that the shaft is larger than the bore. A negative reading (the minus sign appears to the left of the digits) shows that the shaft is smaller than the hole, and the piston will fit. The caliper shows you how much material you need to remove from either the shaft or the bore to make them fit.

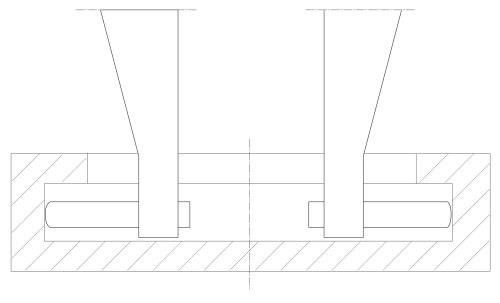

When you need to bore a workpiece but not go all the way through, you might want to know how much material remains between the bottom of the bore and the other side of the workpiece. Your electronic caliper can display this distance for you.

First, use the outside jaws to measure the total thickness of the workpiece. Before you remove the caliper from the workpiece, press the button to zero the caliper while it is still set to the thickness of the workpiece.

Now, use the depth rod to measure the depth of the bore. The caliper reading (shown as a negative number) is the remaining thickness between the bottom of the bore and the other side of the workpiece.

All of these checks can be performed by your everyday digital caliper, the basic shop tool. But have you ever seen those super-duper Swiss Army knives that are loaded with a host of extra tools, such as scissors, ballpoint pens, a magnifying glass and USB sticks? These knives have tools that can do just about anything.

Well, the same is just about true of the universal digital caliper. It has the ability to mount optional contacts within its standard measuring jaws that increase the tool’s versatility. Do you have a groove in a part that measures less than 0.080-inch wide? A standard caliper would have a tough time making this outer-diameter measurement, but this is not a problem for the universal caliper. Just whip out the special blade contacts, snap them into place and you’re good to go. Have a similar check on an inner diameter? Well, there’s an anvil set for that, too, specially made with a thin blade and radiused tip. Snap these into place, and the inner diameter becomes just another measurement. Even if the groove is less than 0.020-inch wide and less then 0.060-inch deep, it can be measured with the tools in the caliper’s bag of accessories.

Have you ever been in a pinch and needed to measure some gears or threads? Purpose-built gages are very precise but quite costly. If you have a special job making only a few parts or a wide variety of gear-like parts that have an even number of teeth, sometimes you can’t justify that special gaging. In that case, standard accessories for the universal caliper will enable you to start making gear checks with the proper ball diameter as called for. The same goes for thread checking. High-precision measuring kits used on some precision comparative gages can be adapted to the universal caliper, which makes it easily adaptable for emergency measurement.

Maybe the end results won’t be as good as uncorking that special wine, but to your boss, you may look pretty good nonetheless.

.png;maxWidth=300;quality=90)