High-Speed Machining

The Costs and Benefits of Horizontal Machining

The shift from vertical to horizontal machining was even more expensive than this shop anticipated. It was also more valuable. Most of the shop’s machining centers are HMCs now—here’s why.

Read MoreControl Package Helps Speed Production

After cutting precision parts in one third of the original time, Task Force Tips was able to justify its initial investment in an Index automatic production lathe fitted with a Siemens control package.

WatchHigh Speed Leads to Lights-Out

This mold maker has become more competitive by establishing a high speed machining process that is predictable enough to confidently run lights-out.

Read MoreInserts Withstand Heavy, High-Feed Cuts

Swapping standard button inserts for a new grade from Ingersoll helped this manufacturer of downhole oil-drilling equipment double throughput on a troublesome arbor milling job in hardened steel.

Read MoreVideo: Linear Motor Machines at Die Tech

Machines with linear motors instead of ballscrews have increased productivity for one die maker.

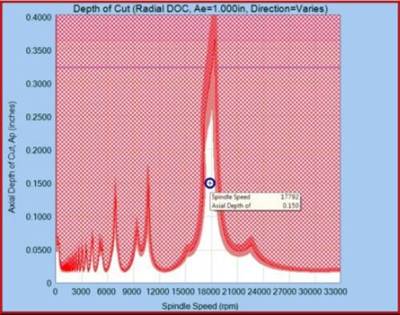

WatchWhat Your Handbook Isn’t Telling You

Tony Schmitz, professor at the University of North Carolina at Charlotte, gives a presentation on machine tool dynamics. Learn the role that this concept plays in realizing your optimal machining center performance.

Read MoreMaximizing Power for High Speed Hog-outs

A reader asks a question related to the rated power of a machine tool spindle.

Read MoreImproving Surface Finish During High Speed Machining

Many factors can affect surface finish. This answer to a reader’s question focuses on imbalance and frequency sensitivity.

Read MoreThe Online Optimizer

Coming soon: The Machine Tool Genome Project promises to let almost any machine shop use its machining centers more productively. Shops will benefit from tap-test findings without personally tapping any of their own machines or tools.

Read MoreSoftware/Tooling Partnership Promises Easier HSM

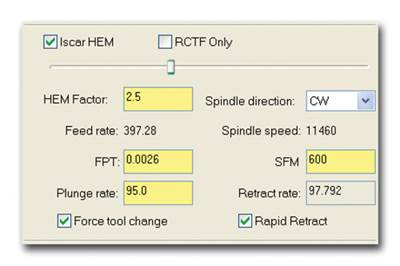

High-efficiency parameters are calculated automatically—partly using a slider that lets the programmer set the level of aggressiveness.

Read More

.png;maxWidth=300;quality=90)