High-Speed Machining

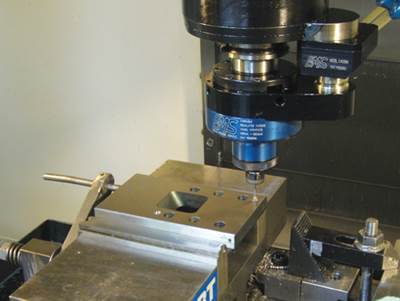

Milling with Air

... not to mention grinding with air. Thanks to high speed spindles powered by shop air, this job shop expands the work its VMCs can do.

WatchHow to Overcome an Acc/Dec Limitation in High Speed Machining

A small pocket in a graphite workpiece limits productivity. Part of the expert’s response is to consider how a lower feed rate might actually be more productive—because the machine will spend more time at the programmed rate.

Read MoreBasic Questions on High Speed Machining

Can HSM apply to turning? Does the “speed” refer to cutting speed or spindle speed? What is the explanation behind lower forces and lower heat generation?

Read MoreHard Milling Isn’t Just High Speed Machining

Milling complex forms in hardened tool steel involves more than just fast, light cuts, says this maker of medical-related injection molds. Here are some of the ingredients of an effective hard milling process.

WatchAnother Angle On HSM

The savings in setup time were welcome enough, but this mold maker found that a 3+2 machining center also accelerated its use of high speed machining.

Read MoreTool for Shallow, High-Feed Cuts Speeds Roughing

“Feed fast, cut shallow.” This strategy, in combination with a cutting tool specifically designed to take advantage of it—the Power Feed+ from Ingersoll—enabled this shop to reduce cycle time on a tough prototyping job by a factor of five and increase insert life by a factor of six.

Read MoreWhen Spindle Speed is a Constraint

Though it won’t replace high speed machining, Boeing sees “low speed machining” as a viable supplement to higher-rpm machines. Using new tools and techniques, a shop’s lower-rpm machining centers can realize much more of their potential productivity in milling aluminum aircraft parts.

Read MoreVideo: Getting the Most Out of Your Standard Spindle

High spindle speed is not needed for high productivity, particularly with the right choice of cutting tool types. Techniques described in this tutorial video relate to plunge roughing, high feed milling and slotting.

WatchVideo: Plunge Roughing in Aluminum

Even in aluminum, plunge roughing can be an effective way to realize high productivity.

WatchVideo: High Feed Milling in Aluminum

Footage shows roughing at 48 cubic inch per minute on a standard-speed machining center.

Watch

.png;maxWidth=300;quality=90)