High-Speed Machining

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Rough Faster With Better Tool Life in Difficult Materials

Optimized roughing, also called high-efficiency milling, is an effective way to improve material removal rates and tool life for titanium and hard-to-machine alloys, but knowing when to use it is as important as knowing how.

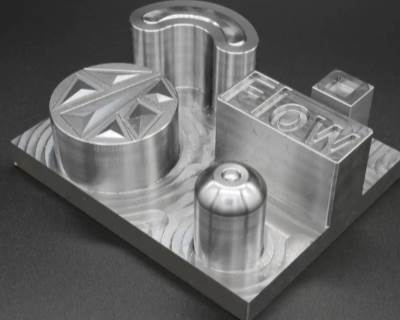

Read MoreHard Milling Replaces Hand Grinding in Finishing Die Components

A focus on repeatability, geometric capabilities and speed led this manufacturer of fine-blanking machines and components to embrace hard milling as its go-to finishing process, eliminating hand grinding.

Read MoreHitting the Zone with Five-Axis Machining

By investing in five-axis machining technology, Advance CNC Machining has done more than just add new capabilities to its roster. It has found a way to achieve something that most of us strive for: a way to work “in the zone.”

Read MoreComposites Specialist Makes CNC Chops Count

Machining capability drives evolution from race car builder to aerospace and defense contractor.

Read MoreHMC Features High Speed, Smaller Footprint

Sold and serviced by Absolute Machine Tools, the HMC is intended to be a low-cost, high-speed machining center meeting the demands of manufacturers with high-volume machining needs.

Read MoreStudy Finds Brass Has Profit Potential for High-Speed Machine Shops

For machine shops with high-speed equipment already on the floor, brass represents an opportunity to capture new profits they might otherwise miss with other materials, according to the study.

Read MoreYCM Alliance Hits IMTS

YCM Technology has joined with other like-minded machine tool manufacturers to take a solutions-based approach to manufacturing.

Eli Plaskett

Senior Associate Editor, Modern Machine Shop

High-Speed Graphite Mill Features Temperature Compensation

GF Machining Solutions’ high-speed Mikron Mill S 400/500 Graphite and Mikron HSM 500 Graphite are dedicated specifically to graphite machining.

Read MoreStarrag Tech Days Highlight Turbine Technology Applications

A visit to Starrag headquarters in Roschacherberg, Switzerland during the company's 2018 technology days revealed new equipment, tools, technologies and machining strategies for turbine manufacturing.

Read MoreMachining Parts for the World’s Largest Digital Camera

SLAC is building the world’s largest digital camera, to be installed inside the Large Synoptic Survey Telescope. Getting there requires the machining expertise of shops like Keller Technology.

Read MoreMMS Looks Back: 1990s - High-Speed Strategies for a High-Speed World

Amid rapid advances in information technology, machines and tools designed for more powerful controls and more capable software enabled shops of the 1990s to mill faster than ever before. This story is part of our 90th anniversary series.

Read MoreHardware for High Metal Removal Rates

Spindle power and shrink-fit toolholding are two assets this shop seeks to use to the extremes of their capabilities.

Read MoreAdding Context to Advanced Milling

For all its focus on machines, cutters, parameters and tool paths, an expo hosted by Methods Machine Tools demonstrated that competitive hard milling increasingly requires looking beyond the workzone and even beyond traditional machining.

Read MoreChiron's Five-Axis DZ 22 Meant For High Speeds and Precision

Chiron’s new DZ 22 precision machining center features twin spindles and a moving gantry design to rapidly and precisely machine various large, complex parts.

Evan Doran

Associate Editor, Modern Machine Shop

Applications Advance for Solid Ceramic End Mills

All they need is speed! Tools for roughing nickel-based alloys can be used in the same processes as carbide tools, just with high rpm and no coolant.

Read MoreHigh-Speed Machine Spindles Reduce Cycle Times

Designed to reduce cycle times in a variety of operations, NSK America’s HES series of machine spindles includes two models programmable from 5,000 to 80,000 rpm.

Read MoreIncrease Machining Efficiency through Machine Monitoring

A manufacturer that is distinctive for its attention to in-cycle machining productivity describes its efforts to obtain efficiency improvements outside of the machining cycle. The shop’s primary tool is a simple, daily, graphical recap that illustrates when each machine tool was and was not making parts.

Read MoreMicromachining Evolution

Challenge Machine continues to add high-speed equipment for the increasing amount of micromachining work it is performing. Here are some lessons it has learned along the way, using tools as small as 0.001 inch in diameter.

Read MoreThe Costs and Benefits of Horizontal Machining

The shift from vertical to horizontal machining was even more expensive than this shop anticipated. It was also more valuable. Most of the shop’s machining centers are HMCs now—here’s why.

Read MoreControl Package Helps Speed Production

After cutting precision parts in one third of the original time, Task Force Tips was able to justify its initial investment in an Index automatic production lathe fitted with a Siemens control package.

Read MoreFour New High-Performance Milling Techniques for 3D Machining

With many 3D milling applications demanding both shorter cycle times and smoother surface finishes, it’s time to review how you go about programming and machining parts. These four strategies will let you rough dramatically faster and achieve astonishingly fine surface finishes.

High Speed Leads to Lights-Out

This mold maker has become more competitive by establishing a high speed machining process that is predictable enough to confidently run lights-out.

Read MoreInserts Withstand Heavy, High-Feed Cuts

Swapping standard button inserts for a new grade from Ingersoll helped this manufacturer of downhole oil-drilling equipment double throughput on a troublesome arbor milling job in hardened steel.

Read MoreVideo: Linear Motor Machines at Die Tech

Machines with linear motors instead of ballscrews have increased productivity for one die maker.

Read MoreWhat Your Handbook Isn’t Telling You

Tony Schmitz, professor at the University of North Carolina at Charlotte, gives a presentation on machine tool dynamics. Learn the role that this concept plays in realizing your optimal machining center performance.

Read MoreMaximizing Power for High Speed Hog-outs

A reader asks a question related to the rated power of a machine tool spindle.

Read MoreImproving Surface Finish During High Speed Machining

Many factors can affect surface finish. This answer to a reader’s question focuses on imbalance and frequency sensitivity.

Read More

.png;maxWidth=300;quality=90)