When Jon Baklund reflects on micromachining, his words demonstrate something almost like awe: “It’s like normal physics go out the window, and you’re dealing with something in the range of kind of a ‘pre-quantum’ world. Your cutters will break if you touch them, but then you can machine metal with them. So it’s a strange thing, this dynamic between speed and materials.”

That tinge of wonder colors my discussion with Mr. Baklund about his journey into dedicated micromachining after decades spent on the shop floor working with all kinds of equipment over the years, from learning how to machine on knee mills with his father, to progressive die making and R&D strategies. Representing something of a new chapter for him, Mr. Baklund considers the micro scale to be about twice the width of a human hair, or 0.015 inch and smaller, “because that’s really where everything changes.”

Taking the time to learn how to effectively make chips at this scale is also precisely where Mr. Baklund says “a lot of companies are missing the boat.” With that in mind, the lessons he has learned over the last few years are worth sharing.

“Can’t Be Done”

“We’re just a small shop next to a cornfield out in Hutchinson, Minnesota,” Mr. Baklund says. But as the brains and knowhow behind Minnesota Micro Molding, Machining & MFG (M5 for short), he and his five employees have carved out a space for themselves doing valuable and challenging micro work in a field (no pun intended) with relatively little competition. “Generally the jobs that we take are the jobs everybody else either doesn’t want to do or says can’t be done,” he says, adding with a chuckle, “Our customers really love us, but they don’t like the fact that they can’t get it done anywhere else.”

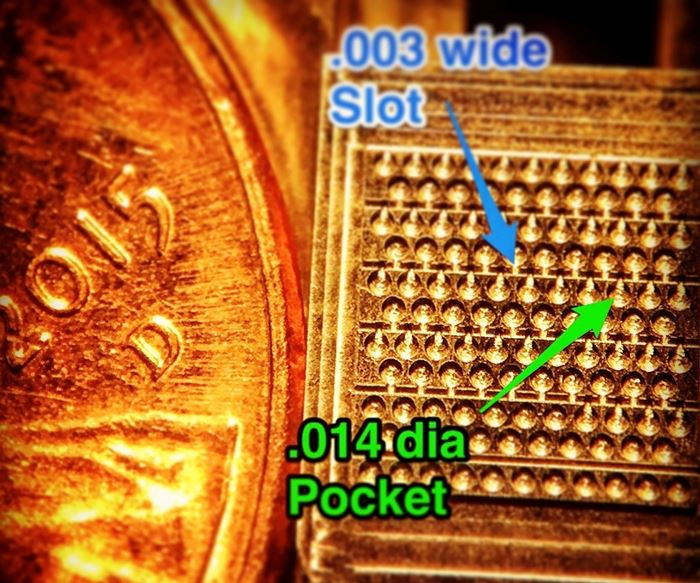

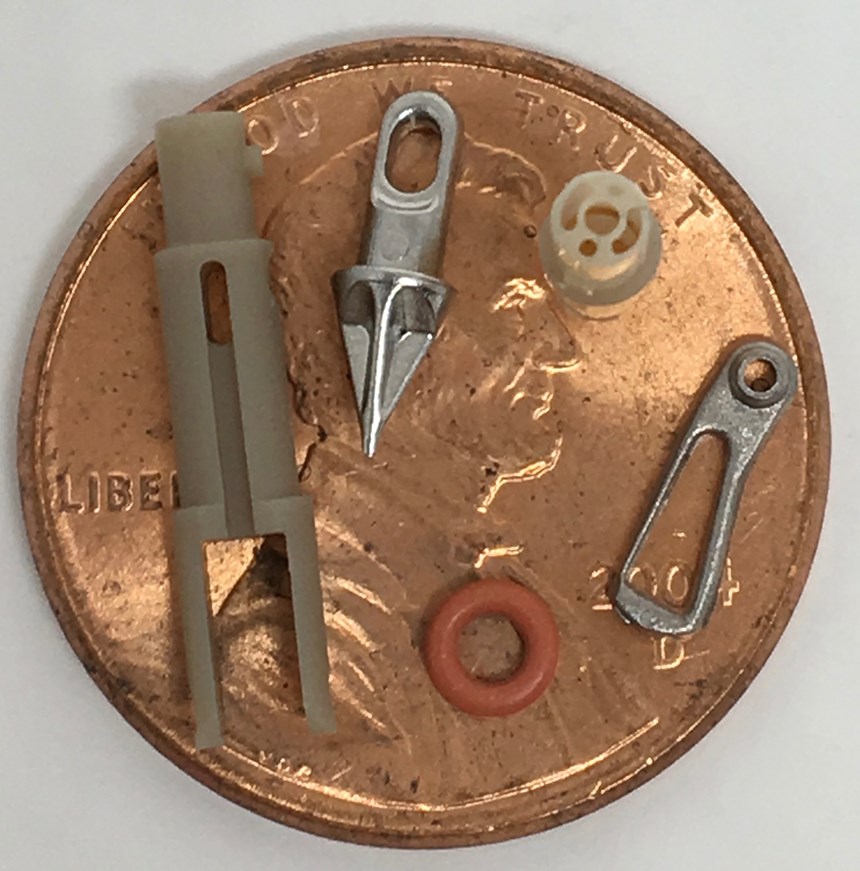

Modern Machine Shop has written about Mr. Baklund in the past, namely in his capacity as proprietor of Baklund R&D. But that was before he started M5 in 2016, thereby dedicating his work to micromachining. Much of M5’s work serves the medical device industry, along with aerospace, military and occasionally electronics. Within the past year, the company has added micromolding capabilities, launching a Production Desktop Micro Molding platform providing complex mold design and for direct-cavity injection of thermoplastic, silicone, metal and bio-absorbable parts of 0.003 cubic inch and smaller. Having begun with micromachining, this move was perfectly natural for M5. As Mr. Baklund puts it: “If anybody is talking to us about micromachining, generally the next conversation is about micromolding; and if we’re talking to people about micromolding, they ask if we do micromachining.”

First Foray into Micromachining

Mr. Baklund’s first foray into micro—a turning point in his career toward the eventual establishment of M5—dates back to the final days of Baklund R&D. The customer needed the shop to machine ceramic-fiber-optic end connectors as well as make fixtures from the same material that could withstand high-intensity heat in an an arc-welding machine. These parts were small, with features and radii that had to be machined with very small end mills.

The challenge? The material in question was full-hard zirconia, rated to 72 HRC.

“They just said to us, ‘Can you machine this?’ And without ever having machined ceramic, I said yes,” Mr. Baklund remembers. “We just started trying different techniques.”

“I thought all I needed was a very accurate machine,” he says. Accordingly, they retrofitted their CNC vertical machining center (VMC) with an air spindle capable of 175,000 rpm, but cutting speed was not enough. “The companies that sell spindle speeders will tell you that you can add high-speed air or electric spindles to you current machines, and you’re up and running. None of that works quite right. You can, of course, do more than you could before you added those capabilities, but the real journey into true micromachining is one that will test your skills and your imagination.”

Apropos of the latter, Mr. Baklund wryly recalls that the solution they settled on came to him in a dream one night after going to bed pondering the problem.

The Lesson of Reciprocating Mass

What the shop learned was the problem of “reciprocating mass,” whichis the limitations of big machines moving big masses to make tiny cuts.

“You can’t just buy a million-dollar machine and expect it to do micro if it’s not built for that,” he says. Micromachining on a standard-size milling machine means that whatever issues it has will be magnified as the scale of the part goes down. “Issues will show up as bad finishes, or you will think that your end mill has dull or chipped edges, and you will see lines in your finishes that look like they are overlaying each other.” This, he explains, is because such a machine has too much weight being asked to change direction too rapidly, resulting in an axial-pendulum effect on the micro level. In the case of the VMC Baklund R&D was using, its column alone weighed about 7,500 pounds. Moving this column back and forth at rates as fast as 160 miles per hour to move a 0.003-inch end mill through stepovers of 0.0005 inch, for example, is just not going to work. Feed rates have to come down dramatically in such a case.

The zirconia project “really pushed our thinking,” Mr. Baklund says. The customer had tried other companies, but nobody else could figure out how to accomplish what these ceramic parts required. According to Mr. Baklund, he and his coworkers didn’t know enough to know that by rights they weren’t supposed to be able to effectively machine 72-HRC zirconia, a material that he says usually receives only straight cuts via grinding due to its hardness.

After this project, Mr. Baklund acquired a Microlution 363 horizontal milling machine with linear motors and a spindle head with very small mass, and a table travel of only 2.5 by 2.5 inches. The linear motors enable something much nearer toinstantaneous start and stop, solving the reciprocating-mass problem of the full-size VMC. M5 currently has four mills capable of micromachining.

Four Considerations for Shops New to Micromachining

Looking back on M5’s experience with micromachining over the past few years, Mr. Baklund’s reflections reveal several keys that shops looking to get into micro work should keep in mind.

1. Philosophy

First and foremost, a shop might have to make some changes in its thinking before beginning. “Since each job is different, and at the micro level all materials are very different, you need to be able to think about the process all the way through before you start,” Mr. Baklund says, adding that micromachining requires a different approach from general machining. “It’s not just punching numbers into a machine and letting the machine do the job. It’s understanding the materials, the cutters, the coolant, the speeds and feeds, the end result that you want, everything.”

Recalling his experience with progressive die making, which requires a particularly acute understanding of materials, clearances, shear forces and more, Mr. Baklund implies that micromachining is as much an art as a science, in which the machinist-as-craftsperson develops an intuitive understanding or “feel” for the relations between all the interacting elements of a project, as well as an abstract understanding through programming and calculations.

Pivoting to his R&D experience, he advises shops that are looking to get into micromachining to “take it slow” and give those who have the interest and aptitude the latitude to try new things and experiment. “Just take your time, try different things and don’t wreck anything. Let’s see how we can make this work,” he tells his machinists, reflecting that “The incentive of doing something new, for a machinist, is generally enough incentive to make something work. Machinists desire to build new things all the time.”

2. Planning

As part of shifting toward a holistic approach to the given project, planning becomes very important. Surprises happen, but when the scale is so small, they need to be minimized if at all possible, which means “your project planning is completely different.”

Mr. Baklund cites workholding as a salient example: “Once you machine a small part, finding a place to hang onto for a second operation is incredibly difficult. Generally, these small parts are not just small, square parts; generally they’re small parts with lots of edges, lots of angles, radiuses inside and outside.” Whereas a part that is large enough to hold in your hand can be clamped down on a second operation, if a micro part has no ideal surface to grab, “you really have to spend some time figuring out how you’re going to machine it and how you’re going to finish it.”

As a result, M5 makes most of its own fixturing using wire EDMs.

3. Machining

Repeating the mantra “take it slow,” Mr. Baklund reminds shops that are experimenting with spindle speeders and using existing equipment that these high-mass machines need to be given slower feed rates along with higher rpms: “You don’t want to put in the speeds and feeds that the small end mills call for into a machine that isn’t built for that. You’ve got to go slow, otherwise you’ll get a lot of errors. Then you’ll think your machine can’t do it.” On the contrary, it can be done.

That said, there is a reason M5’s four micro mills are built with micromachining specifically in mind. “Micro takes a very specific subset of qualities on a machine to be done correctly,” Mr. Baklund says.

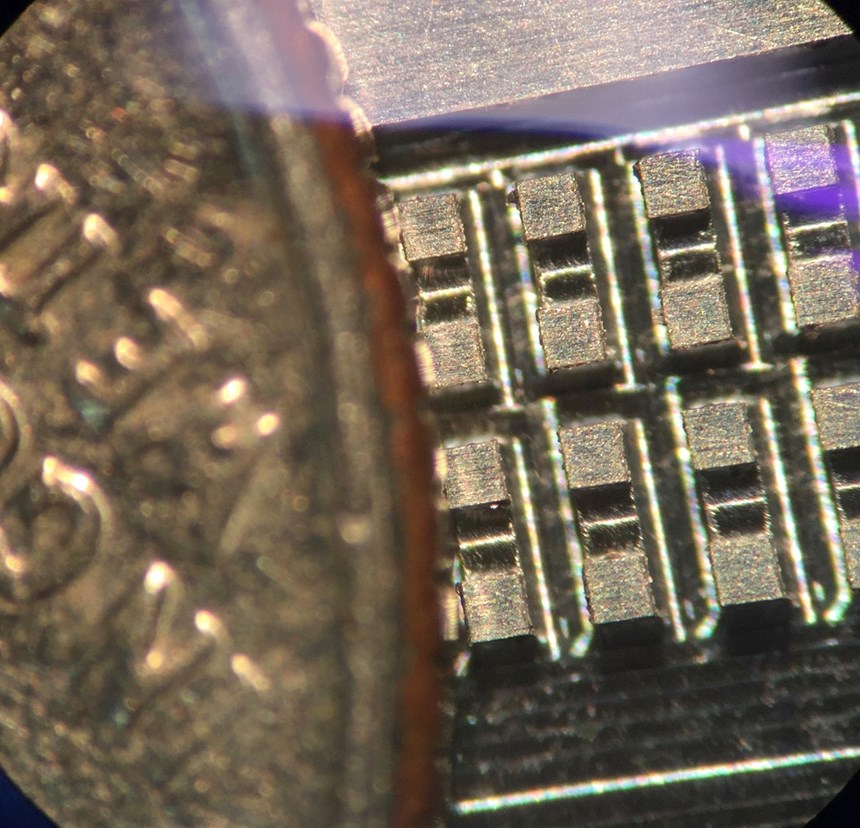

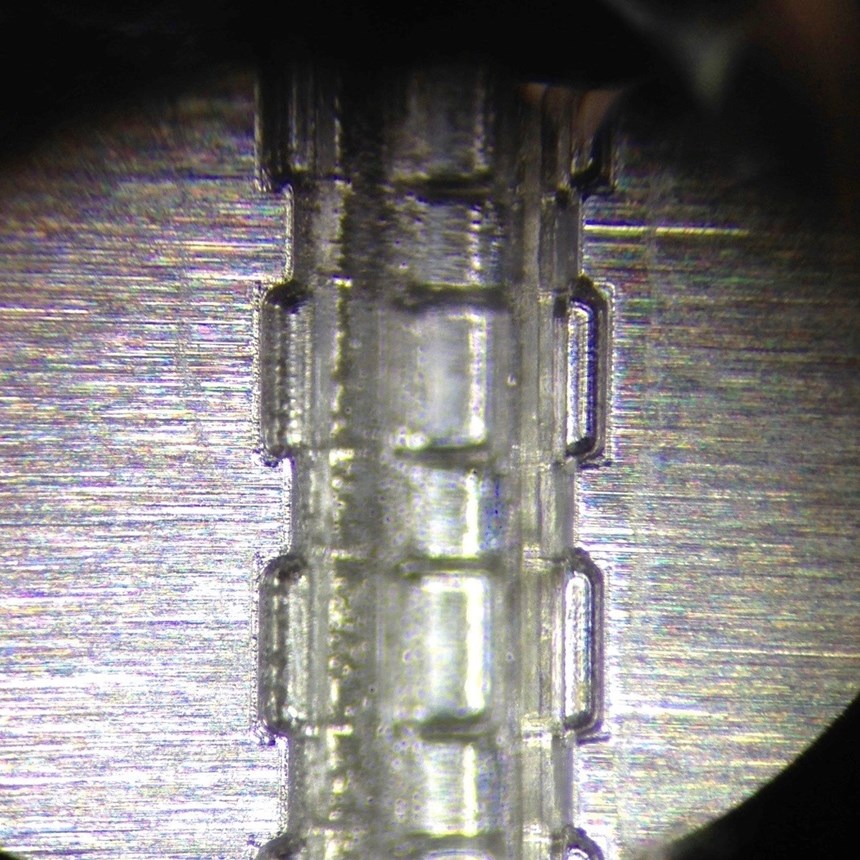

4. Finishing and Inspection

Finishing micro parts presents a new challenge, since machining errors can be too small to see with the naked eye. While calipers can be used sometimes on certain features, something more is usually needed to properly inspect such small workpieces. As a result, M5 relies on microscopes, vision systems and optical comparators for its inspection.

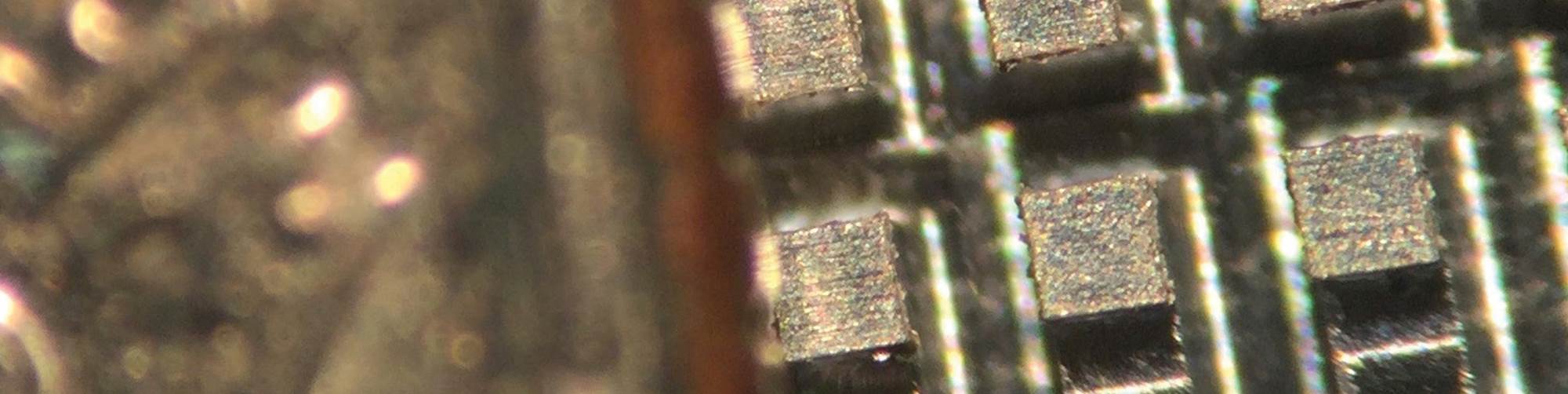

Micro-burrs (such as those seen under the microscope in the second photo in the slideshow above) often have to be deburred by hand under the scope. Some parts may be amenable to blasting with a light mist of glass beads, but often enough, these beads are too large to fit into the slot on a micro workpiece like the one referenced above, with slots as small as 0.005 inch. On the other hand, electropolishing risks breaking the edges on part features too much, producing rounded edges, which is its own problem. At the micro scale, edges that are not square mean there is effectively no feature—an unacceptable result for, say, a micro mold. One does not put a 0.005-inch chamfer on a 0.005-inch standoff, Mr. Baklund chuckles.

Sometimes, parts can be machine-deburred by simply running blank passes on the part. However, this too needs to be included in project planning, since if a machinist completes the part and removes it from the machine before trying this, it will no longer be possible.

Related Content

Watchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

Read More3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)