Composites suppliers, fabricators respond to coronavirus

Companies across the composites industry supply chain share how the COVID-19 pandemic is affecting their businesses, and how they are available to help.

Editors’ note: The editorial team at CompositesWorld has received a number of messages and press releases from composites industry suppliers and fabricators affected by the COVID-19 pandemic. These messages and responses can be found below, and we will continue collecting information and stories here as we receive them. If you have a message you’d like to share with the composites industry through this page, please send an email to jeff@compositesworld.com.

For more information on business conditions, see Gardner Intelligence. For guidance on approaching coronavirus as an employer, we recommend the CDC website.

Schmidt & Heinzmann on course of growth despite worldwide risk of recession

May 26, 2020

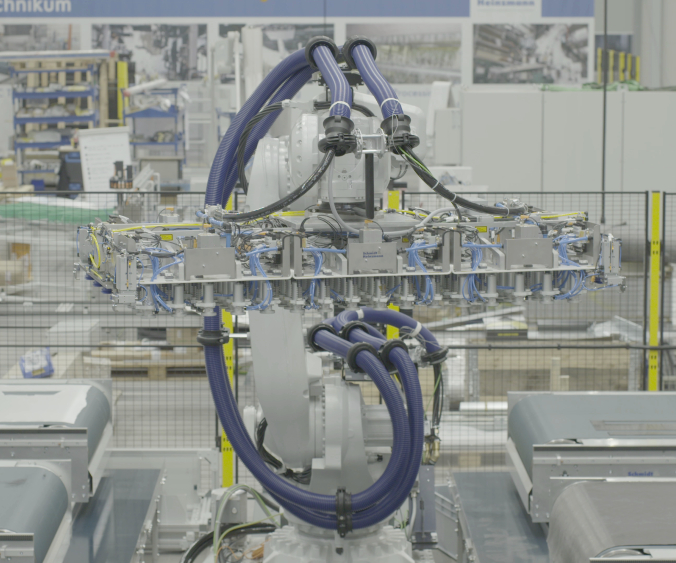

Despite emissions scandals, the switch to electromobility and the coronavirus pandemic, Schmidt & Heinzmann (Bruchsal, Germany) expects the highest turnover in company history in 2020, because of a worldwide rising demand for machines for fiber-reinforced plastics, which are made in Bruchsal. Its course of growth can be contributed to the medium-sized company’s technological leadership, which has been built up in the last year through continuous development of technologies and machines and has, as a result, given the company a very high growth rate, especially in the field of automation for processing of semi-finished composite products.

Schmidt & Heinzmann is also planning to upgrade in physical space and personnel. The company has already reaching its limits in its new production hall which was built in the beginning of 2019, and they require more staff in thefields of control engineering and robotics to match the current growth rate. Managing director, Matthias Feil notes, “We are really happy about the current situation. This shows that we have done some things right in the past. The investment in research and development continues to bear fruit, even in the current economical difficult situation.”

Automated cutting and stacking system. Source | Schmidt & Heinzmann

Johns Manville produces nonwoven fabric for medical gowns

May 22, 2020

Source | Johns Manville

Johns Manville (Denver, Color., U.S.), a company with a focus in poylester nonwoven products, continues to produce nonwoven fabric for the manufacturing of disposable medical gowns at its plant in Spartanburg, South Carolina. They began their production early in May in response to the coronavirus pandemic.

“Our teams are working quickly to create solutions and manufacture a new coated polyester spunbond nonwoven fabric,” says John Vasuta, President of Johns Manville’s Engineered Products business. “We are going through unprecedented times – so every step to support health care workers and others on the front lines helps right now.”

In April, production of nonwoven media started in Richland, Mississippi, for the manufacturing of face masks. The disposable medical gowns are the second move by Johns Manville to develop and launch a product that can improve the safety of people in potential direct contact with the COVID-19 virus.

The new polyester spunbond nonwoven, known as Evalith® 017/120H3, is designed for the production of Level 3 medical gowns. Compared to Level 1 and Level 2 medical gowns, the nonwoven is better prepared, including a liquid barrier performance, with the same amount of comfort and stitch-strength.

Boeing Dreamlifters transport PPE to South Carolina for COVID-19 recovery efforts

May 21, 2020

Source | Boeing

Boeing (Chicago, Ill., U.S.) has been deploying Dreamlifter aircraft to transport more than 150,000 protective eye goggles and face shields from China to the United States. On May 11, Boeing worked in partnership with the Medical University of South Carolina (MUSC) to deliver personal protective equipment (PPE) to frontline health care professionals in the MUSC system using three Deamlifters.

The MUSC Health team will use the PPE as they support the revitalization of the economy and ramp-up COVID-19 community outreach efforts, including diagnostic testing and antibody testing, across South Carolina.

Similar to previous airlift missions flown by the Dreamlifter – a converted Boeing 747-400 Large Cargo Freighter – the medical cargo was transported in the lower lobe of all three aircraft, while 787 component parts were flown in the main deck cargo hold. Boeing donated the cost of the mission transport, with Atlas Air operating the flights on behalf of Boeing. Boeing has scheduled additional flights, to deliver a total of 400,000 units of PPE to MUSC, in the near future.

Consultancy firms partner to offer advisory services to composites

businesses through pandemic

May 19, 2020

The firms' leaders, Frank M. Bruns of Alpha Executive Advisory (left) and Dr. Michael Effing of AMAC (right) , have more than 60 years of general management experience in the composites industry. Source | AMAC

In response to the coronavirus pandemic, industrial and business consulting company AMAC (Aachen, Germany) announces that it has signed a cooperation agreement with consultancy firm Alpha Executive Advisory (Heidelberg, Germany) to jointly offer advisory services in business coaching, acquisitions and divestitures, business transformation and crisis management to the composites industry.

The companies say the goals of the cooperation are to identify capabilities and financial strength for companies looking for expansion or divestiture; to support start-up firms looking for faster market penetration; and to ease interim management transitions and other strategic decisions.

Royal DSM launches collaborative digital platform to connect manufacturers to healthcare facilities

May 19, 2020

Source | Royal DSM

Royal DSM (Geleen, Netherlands), a science-based company in nutrition, health and sustainable living, has launched UNITE4COVID, a digital, open, collaborative marketplace designed to provide solutions for healthcare professionals, as well as operate as a forum and collaboration hub for inventors, manufacturers and certification labs in response to the coronavirus pandemic.

Healthcare professionals as well as organizations, institutions and companies looking to protect their patients, employees and customers can access UNITE4COVID to see and request the currently available solutions. In addition, solution providers – from inventors to production hubs – can utilize the platform to share ideas, solutions, capacity and more. The platform is intended to bring together players in additive and traditional manufacturing industries in one collaborative marketplace.

SGL Carbon’s Q1 2020 results show no significant impact from coronavirus, though negative change in Q2 is expected

May 19, 2020

SGL Carbon (Wiesbaden, Germany) reports that its first quarter results have not yet seen signficant impacts from the coronavirus pandemic, falling within the scope of initial forcasts. However, SGL says its production processes have been affected significantly by customers’ and its own temporary production stops, reduced production levels as well as demand reductions since the beginning of the second quarter 2020. Accordingly, the company currently expects second quarter sales revenues to decline substantially compared to the previous year.

In the first quarter, the company reported sales revenues slightly above the guidance corridor of €220 to 240 million published on March 12, 2020. In total, Group sales at €247 million was approximately 15% below the prior year level. SGL attributes this development to changes in the lithium-ion battery supply chain in its Graphite Materials & Systems (GMS) business unit as well as to restructuring-driven lower sales in textile fibers in the Composites – Fibers & Materials (CFM) business unit. As planned, Group recurring EBIT decreased by approximately 50% to €9 million. SGL Carbon implemented various measures to counter the economic impact of the pandemic at an early stage. For this reason, liquidity developed very favorably compared to year-end 2019 and in contrast to the usual seasonal pattern and improved from €137 million to approximately €150 million.

Sales revenues in the business unit CFM developed as expected at €104.5 million euros, approximately 9% below prior year’s level (currency adjusted: minus 10%). Declining sales in the market segments Automotive and Aerospace were compensated by higher than expected sales growth in Wind Energy. Sales in Industrial Applications were stable and thus also slightly better than planned. Recurring EBIT grew to reach €3.7 million compared to the break-even level of the prior year quarter. Main drivers for this development were the earnings improvement measures implemented last year, particularly the restructuring in Textile Fibers, price increases in the market segment Wind Energy as well as the segment-wide improvement of the operational performance. Due to its exposure to the market segments Automotive and Aerospace, which are more than proportionately negatively impacted by the Corona crisis, the reporting segment CFM is significantly affected by the recent developments in these customer industries. However, these developments have not yet materially impacted the first quarter.

Sales revenues in the business unit GMS in the first quarter 2020 saw a decline of 19.1% to €134.6 million, but were in line with expectations due to the changes in the supply chain in the lithium-ion battery business. All market segments declined compared to the prior year period with the exception of semiconductors.

In light of the uncertainties surrounding the further development, the duration as well as the impacts of the pandemic, on April 1, 2020, the Board of Management of SGL Carbon SE decided to suspend the guidance for the fiscal year 2020 as published in the Annual Report 2019.

Pelican Wire donates wire for face masks

May 15, 2020

Source | Trent Dunn

In an effort to contribute directly to the fight against COVID-19, Pelican Wire (Naples, FL., U.S.), a global manufacturer for custom wire solutions, has donated precision wire to ZSK Technical Embroidery Systems (St. Louis, MO, U.S.), an embroidery equipment manufacturer that specializes in technical embroidery that includes putting wires and nonstandard materials into fabrics. Bendshape, a wearable electronics company, is also a development partner in this project with ZSK, who is taking the lead on production.

While remaining open as an ‘essential business’ during the coronavirus pandemic, Pelican Wire has been manufacturing numerous custom wire solutions for other essential business partners in key industries, but were pleased to join in a ‘front-line cause’ as this project offered. Dr. Topher Anderson, technical embroidery manager for ZSK says “All three companies, Pelican, BendShape, and ZSK are aligned in their mission to help have a direct impact on attempting to reduce the spread of COVID-19. We appreciate their support and it came when we needed it the most.”

Faced with the shortage, Sonimat supplies mask manufacturers

May 13, 2020

Source | Europe Technologies

Faced with the growing demand for protective masks during the coronavirus crisis, the Europe Technologies company, Sonimat, an ultrasonic equipment manufacturer, is reviving its production of equipment necessary for mask manufacturing. Relaunch of its mask welding machines has not been necessary since the H1NI flu in 2009. Since the global spread of the pandemic, requests worldwide have swelled. As a result, European Technologies’ mask welding modules have been revitalized since late March 2020, which has allowed Sonimat to weld up to 100 masks per minute and serve its global clients.

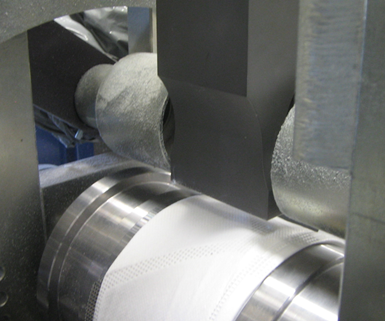

FET non-woven melt spinning technology suitable for medical face mask applications

May 12, 2020

Source | David Stead

Fibre Extrusion Technology (Leeds, UK) reports its non-woven spinning system technology is suitable for medical face mask application. Since the onset of the coronavirus pandemic, worldwide demand for medical grade masks has stretched manufacturing capacity which relies heavily on the specialist melt-blown process for non-wovens.

FET’s melt spinning system is a tried and tested pilot and laboratory scale format for non-woven production. Trials are currently being concluded and samples produced of polypropylene melt blown non-woven materials suitable for applications in FFP2 and FFP3 medical masks.

Although the FET system is primarily designed for R&D and pilot scale applications, trials are proving it to be suitable for low volume production of the face mask central filter materials. This system is ideal for continued development of non-woven materials for this application and offers a made-to-order solution for small scale production.

Manufacturing giants and niche suppliers alike across the globe are adapting their efforts to provide materials and products to combat the pandemic. FET has received numerous inquiries for its non-woven melt spinning system and is currently engaged with companies based in Germany, Italy, the UK and elsewhere, running trials, preparing samples and defining specifications.

FET’s in-house process development laboratory is currently running at full capacity to meet unprecedented demand for specialist non-woven materials as a result of the crisis.

Quarantreat offers fast-build medical isolation studio for COVID-19 containment

May 8, 2020

Rapid dispatch design uses LitePan composite structural insulated panels and LiteTex thermoplastic composite laminates. Read the full story here.

Coastal Enterprises precision board used to make PPE

May 7, 2020

Source | Coastal Enterprises

Coastal Enterprises (Orange, Calif., U.S.) reports that its high-temperature PBHT Precision Board Urethane tooling substrate is being used to form plastic parts used in medical devices, face shields and other personal protective equipment (PPE).

For example, the company says that Monster City Studios (Fresno, Calif., U.S.) used its PBHT Precision Board to form a plastic face shield as part of a push to support hospitals and help alleviate the shortage of PPE. With 1-3 day lead times for most standard-sized blocks, the company says this product enables new tooling to be built in a matter of days.

AMRC converts new R&D facility into ventilator production venue

May 5, 2020

Source | AMRC

The University of Sheffield Advanced Manufacturing Research Centre (AMRC, Catcliffe, U.K.) Cymru reports that it has stepped up to become a production facility for thousands of vital medical ventilators.

Turning AMRC Cymru, a new facility that officially opened in November 2019, into a production facility for ventilators was brought up as a possibility on March 16, when the call for increased ventilator production was announced in the U.K.

The Ventilator Challenge UK consortium came together after the Prime Minister made a plea for thousands of ventilators to be delivered to the National Health Service (NHS) within a matter of weeks. Under the leadership of the High Value Manufacturing (HVM) Catapult, of which the AMRC and the Nuclear AMRC are a part, the consortium is focusing production on two existing ventilator designs which meet the high-level specification, one made by Penlon and the other by Smiths Medical.

AMRC Cymru manufactures two key sub-assemblies of the Penlon ventilator: the absorber and the flow meter units. Now authorized by the Medicines and Healthcare products Regulatory Agency (MHRA) for use in hospitals, following extensive testing, the government has confirmed an order for 15,000 Penlon devices. Hundreds of units were built in the first few days, with production now being further scaled up.

At AMRC Cymru, there are eight assembly lines for each sub-assembly, requiring 88 operators per shift. There are two shifts a day, with everyone working in a four days on, four days off pattern. That means 352 shop floor staff; add in the office, logistics, security and cleaning staff and it takes the full complement to around 500, the company says. The facility is also adhering to strict health and safety guidelines.

Vyaire Medical, Spirit AeroSystems partner to increase ventilator production

May 4, 2020

Respiratory healthcare company Vyaire Medical Inc. (Chicago, Ill., U.S.) and aerostructures manufacturer Spirit AeroSystems (Wichita, Kan., U.S.) have announced a new manufacturing and supply collaboration to build critical care ventilators at a converted facility in Wichita, Kan., U.S. The temporary partnership has been developed to allow Vyaire to quickly ramp up production of critical care ventilators. This partnership furthers earlier action taken by Vyaire to accelerate production of ventilators and other related respiratory equipment at its primary production facilities based in North America.

Design of the production system is underway, and teams are readying the facilities with production materials, critical equipment and building infrastructure to stand up manufacturing lines. Training of staff is proceeding and approximately 700 Spirit employees will be assigned to this project as production ramps up.

Vyaire was chosen by the U.S. Department of Health and Human Services (HHS) to provide 22,000 of its LTV2 2200 ventilators to the U.S. Strategic National Stockpile. In addition to the national stockpile request, Vyaire is working with state and private hospital and health system clients to ensure delivery of ventilators to areas of greatest need. The manufacturing and supply collaboration will help to balance the needs of clinicians urgently treating patients at the bedside with the commitment to fill or replenish strategic stockpiles. Vyaire is working with customers, including the HHS, to ensure patient need is prioritized and that critical care ventilators are distributed to areas in most need.

KraussMaffei produces facial visors for regional institutions in Hannover

May 1, 2020

In response to shortages ofpersonal protection equipment (PPE), KraussMaffei's extrusion division (Hannover, Germany) has begun producing reusable facial visors. These visors are designed to complement the protective equipment of medical and healthcare professionals as well as of persons working in jobs with a high number of interpersonal contacts. The essential visor component is a stable, transparent film that can be disinfected with common disinfectants, is impermeable to droplets and keeps hands away from the face. So far, KraussMaffei has supplied its face visors several hospitals in Hannover.

The company says it is producing approximately 120 visors per week, utilizing its 3D printers around the clock to maintain production. The visors are composed of five components: a rigid plastic holder produced on a 3D printer, a rubber strap to secure the visor to the head, a transparent film and two screws designed to attach the film to the holder. Facial visors can certainly not replace a face mask that has to be worn additionally, but they protect the eyes in particular, through which pathogens can also enter the body by airborne infection. The visor is exchangeable and can be cleaned with hot water and disinfected using standard disinfectant spray solutions.

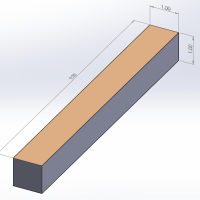

General Plastics offers polyurethane foam strips for use on face masks

April 30, 2020

Source | General Plastics

In response to the increased need for Personal Protective Equipment (PPE) by front-line caregivers, General Plastics (Tacoma, Wash., U.S.) reports that it is utilizing its 78 years of experience to assist in the supply of face-shields or masks around the world.

With capacity to create hundreds of thousands of high-quality soft, flexible, comfortable polyurethane foam strips with a Pressure Sensitive Adhesive (PSA) backing each day, General Plastics says it is ready to serve the supply chain for face-shield manufacturers of all sizes, both corporate or volunteer. These strips are available in the size 1″x1″x9″ for immediate inclusion in face-shield assembly. One shipment box contains 600 pieces of these strips.

Scott Bader launches second thickener for hand cleansers

April 28, 2020

As part of its coronavirus relief efforts, Scott Bader (Northamptonshire, U.K.) reports that it has launched Texicryl 13-322, a second new thickener for both ethanol and IPA-based hand cleanser formulations.

In March, Scott Bader launched Texicryl 13-321 (scroll down for more on this story), a new thickener developed within 10 days, to help the global shortage of hand cleanser ingredients. High demand from around the world, the company says, has led to the launch of a second thickener specifically developed for use in both ethanol and IPA-based hand cleanser formulations.

CGTech continues operations, offers virtual training and tools

April 28, 2020

CGTech (Irvine, Calif., U.S.) reports that it is continuing operations without disruption and is currently offering a variety of virtual tools to support customers working from home:

- The company’s VUE users’ exchange meetings, which are developed to express customer appreciation, provide updates, and work with users to improve software and user experience, will be held virtually in 2020.

- Temporary VERICUT software licenses are available for those working from home. CGTech asks that those interested contact their Sales Engineer for more information.

- Web Training is available for VERICUT software. The company can also set up web training for specific programming groups.

- Data for NC machines that need configured in VERICUT can be sent virtually.

Boeing to resume 787 operations in South Carolina

April 28, 2020

Boeing (Chicago, Ill., U.S.) reported on April 28 that it will resume 787 operations at Boeing South Carolina (BSC), with most employees returning on May 3 or May 4. Read the full story for more.

Shape maintains skeleton staff during April and May

April 24, 2020

Shape Machining Ltd. (Witney, U.K.) reports that it is open for business with a skeleton crew available to program, machine, hand finish and inspect patterns, foams and jigs. Due to the coronavirus pandemic, the business was closed at the end of March, but the company has decided to reopen to deliver current projects while respecting goverment guidelines such as social distancing.

Source | Shape Machining Ltd.

Shape Machining specializes in machining metallic tools, epoxy tooling block patterns, Rohacell foams and the trimming of carbon fiber parts for the automotive, motorsport and aerospace industry.

AOC resins support manufacture of emergency hospital wards

April 24, 2020

Read the full story.

TPI Composites to collaborate with state of Iowa on COVID-19 testing

April 23, 2020

Global composite wind blade manufacturer TPI Composites Inc. (Scottsdale, Ariz., U.S.) reports that as a result of an increase in regional COVID-19 cases and 28 confirmed new cases during the past week among associates at TPI’s Newton, Iowa manufacturing facility, the company is collaborating with the state of Iowa on increased COVID-19 testing for this facility.

TPI plans to voluntarily pause production at its Newton, Iowa manufacturing facility until the middle of next week in order to do another deep clean of the facility and to implement this more rigorous testing plan, which will include testing all Newton associates. TPI’s associates will be paid during the production pause and TPI also plans to provide protective masks to its associates’ family members for use at home.

In early March, TPI implemented best practices learned from its Chinese operations during the COVID-19 outbreak in January and February including implementing mandatory temperature checks for anyone entering the factory, mandating social distancing and when not practical due to the manufacturing process mandated wearing PPE, and disinfecting the entire facility at least once per day.

Hexcel announces additional cost reduction actions

April 21, 2020

In addition to the measures outlined in the Hexcel’s (Stamford, Conn., U.S.) business update on April 6, 2020 (scroll down to see this original announcement) the company announced the following cost reduction actions alongside its first quarter results:

- Eliminating contract labor and overtime while reducing discretionary spending to essential items only.

- Reducing the company’s total workforce to align operations with customer demand.

- Reducing base pay for company President Nick Stanage and cash compensation for each member of the Board of Directors by 50% until further notice.

- Implementing temporary salary reductions and unpaid furloughs for all salaried employees whose jobs are not eliminated.

- Reduced Capex spend to safety critical and essential maintenance only.

- Suspending the company’s 401(k) match on employee contributions until year end.

- Suspending the company’s employee stock purchase plan through year end.

- Suspending the company’s dividend and pausing its stock buyback program. Both decisions will be reviewed quarterly.

The company will continue to evaluate the operating environment and may make adjustments to the actions outlined above as business conditions warrant.

TRB produces face visors for healthcare workers on the COVID-19 frontline

April 21, 2020

Source | TRB Stuctures

TRB Lightweight Structures (Huntingdon, U.K.) is producing vital personal protective equipment (PPE) based on the Foster + Partners design in the fight against COVID-19. The company has redeployed personnel and machinery that normally create advanced composite components for electric vehicles to produce an innovative reusable face visor, and is now generating 1,000 of these per day.

To help replace global shortages in PPE, TRB has adapted its expertise and kit cutting equipment to manufacture face visors for the U.K.'s National Health Service (NHS). The company is now in full production and able to make one face visor every 50 seconds, TRB says.

This simple, reusable face visor has been created by London architects Foster + Partners, with an open-source design aimed specifically at fast mass production.

Johns Manville starts production of nonwoven media for face masks

April 21, 2020

The Johns Manville (JM; Denver, Colo., U.S.) plant in Richland, Mississippi started production this month to make nonwoven filtration media that will be used to create face masks to prevent the spread of COVID-19.

Given the shortage of face masks in the U.S. and Europe, JM’s Engineered Products business decided to build on its existing capabilities and help fill the market demand. “Our high-performance nonwoven material is designed to provide high levels of filtration for various types of face masks,” says John Vasuta, president of JM’s Engineered Products business.

JM media meets or exceeds Level 1 BFE 95% (Bacterial Filtration Efficiency) and VFE (Viral Filtration Efficiency) requirements. These results were verified by an FDA-registered national laboratory.

Porcher Industries launches mass production of masks

April 20, 2020

Source | Porcher Industries

Thermoplastic composites and technical textiles specialist Porcher Industries (Eclose-Badinières, France) has adapted part of its factory capacity for the mass production of reusable masks certified by the DGA UNS-1. Started in early April, production capacity has reached 1 million masks per week, Porcher says.

The masks' new hydrophobic filter material has obtained UNS-1 certification from the DGA. The masks are said to be washable at 60°C and can be reused 10 times if conditions for use are respected. Porcher also says they are quick drying and do not lose their shape. They are intended for non-medical purposes to prevent the projection of droplets, and can be used by professionals in contact with the public, such as the police and checkout personnel.

Results of DGA protocol for Porcher Industries filter material designed for production of AFNOR protective masks Spec. S76-001:2020 UNS-1 for non-medical purposes:

- Filtration: 97% for 3 microns and 93% for 1 micron

- Breathability: 139L.m-2.s-1

- Performance criteria: AFNOR SPEC S76-001 (DGA report no.: RP/20-2307/DGA MNRBC/2000305/NP)

- Reusable and washable mask at 60°C in household conditions.

- Quick-drying (air) hydrophobic material.

- Dimensional stability.

Bucci Composites in Italy restarts operations

April 17, 2020

After a three-week shutdown caused by coronavirus outbreak in Italy, this composites fabricator returns to work (carefully).

Hexion repurposes mixing machines to produce hand sanitizer

April 16, 2020

Thermoset resins supplier Hexion Inc. (Columbus, Ohio, U.S.) is using its global resources to produce large quanitities of hand sanitizer to combat challenges associated with COVID-19.

Two manufacturing sites, one wholly owned and a joint venture, expect to produce large quantities of hand sanitizer by repurposing mixing machines typically used to produce other products. Hexion’s Letmathe, Germany site has already begun producing hand sanitizer, while the company’s joint venture in Bunbury, Western Australia is taking the final steps to begin producing in the coming weeks. These two sites alone expect to initially produce approximately 25 metric tons, Hexion says. In addition, four other sites in the network (Brisbane, Australia; Deer Park, Texas, U.S.; Solbiate, Italy; and Mountview, New Zealand) have produced smaller “laboratory-scale” batches for use by Hexion associates.

In recent weeks, the company has contributed its chemical products or donated personal protective equipment (PPE) wherever possible for COVID-19 relief, including:

- Hexion’s Application Development Center in Shanghai has donated masks to a local hospital;

- The company’s manufacturing sites in Springfield, Oregon, U.S. and Pernis, Netherlands, offices donated PPE to medical centers in their respective cities;

- Hexion’s Lakeland, Fla., U.S. site contributed several drums of isopropyl alcohol, which can be used as a surface disinfectant, to local law enforcement;

- Hexion’s Iserlohn, Germany, facility is providing fresh food to the trucking companies delivering to the site; and

- The Morganton, N.C., U.S. site donated glycerin, a key raw material for the production of hand sanitizer, to a local distillery.

NCC donates thousands of PPE to help protect frontline workers

April 14, 2020

Source | National Composites Centre

The National Composites Centre (Bristol, U.K.) has donated thousands of pieces of personal protective equipment (PPE) to local hospitals and medical facilities to help them during the coronavirus pandemic.

Donations include 32,000 gloves, 1,350 coveralls, more than 100 pairs of safety glasses, more than 60 masks and three powered respirator hoods. All PPE donated is of the required standard for medical use, with high levels of fluid resistance, NCC says.

PPE supplies have been given to Royal United Hospital (Bath), Southmead Hospital (Bristol), Weston General Hospital (Weston-Super-Mare) and Prince Charles Hospital (Merthyr Tydfil). They have also been delivered to a local doctor’s surgery near the NCC’s facility in Emersons Green, Bath and North East Somerset Council to be distributed to care homes in the area, and ER Systems Global, which supports the NHS with ambulance services.

The NCC is also supporting composites distribution leader, GRP Solutions (Havant, Germany), along with its partner companies, GRP Consumable Solutions and Total Composite Solutions, with the #ppe4nhs campaign. They are also part of the VentilatorChallengeUK Consortium, led by Dick Elsy, CEO of the High Value Manufacturing (HVM) Catapult, which has been working hard to investigate the production of a range of ventilator design options to meet a high-level specification for a Rapidly Manufactured Ventilator System (“RMVS”) developed by clinicians and the Medicines and Healthcare products Regulatory Agency (“MHRA”).

Non-profit VentLife formed to develop low-cost, clinically-proven ventilators

April 14, 2020

VentLife, a nonprofit under the umbrella group the Giving Back Fund, has developed a novel mechanical ventilator specifically targeted to meet the needs of COVID-19 patients. Based on first principles, with input from over a dozen medical doctors, engineers and entrepreneurs, the device has been designed to work effectively at a low cost. The VentLife team is located all over the U.S. and is led by Glen Meyerowitz, a former Space X engineer, now graduate student in Electrical and Computer Engineering. Part of this team is Jason Kleinhenz, training and marketing manager for Exact Metrology (Cincinnati, Ohio and Brookfield, Wis., U.S.), a comprehensive metrology services provider which serves the composites industry. VentLife is seeking funding and partnerships to bring this device to market as quickly as possible.

Learn more about the project, team, and how to donate through their site, https://www.ventlife.org/.

BMComposites to reopen April 14

April 9, 2020

Following the confirmation by the Spanish government, BMComposites’ (Mallorca, Spain) workshop in Son Morro will reopen on Tuesday, April 14 while following strict hygiene protocols. The company says its boatbuilders and project team will be working in STP from Tuesday and will be following all procedures advised by the Health Authority and STP.

A&P Technology produces face shields, supports healthcare relief efforts

April 8, 2020

Braiding specialist A&P Technology (Cincinnati, Ohio, U.S.) continues to operate as an essential business supplying critical industries. While the company’s manufacturing floor maintains normal production activity, it has redirected its Shop and Fabrication teams to focus on production of face shields. By next week, A&P hopes to have more than 10,000 fully assembled units to donate directly to front line healthcare workers. In addition, the company is evaluating the possibility of braiding the elastic band required for these face shields, due to limited availability of the band.

In addition, A&P’s production directly supports manufacturers focused on healthcare relief efforts during this pandemic, while maintaining supply to applications in critical industries. The company’s braided materials enable the build of quick deploying field hospital tents, emergency response shelters, medical treatment beds and hospital screens.

Eastman Machine Co. and partners produce face shields for Utah hospitals

April 8, 2020

Source | Eastman Machine Co.

Eastman Machine Co. (Buffalo, N.Y., U.S.), which manufactures cutting tables used in the composites industry, has partnered with DPS Skis (Salt Lake City, Utah, U.S.), Goal Zero (Bluffdale, Utah, U.S.) and Petzl to manufacture medical-grade reusable polycarbonate face shields for the Utah Department of Health.

Production of the face shields has commenced at DPS Skis’ Salt Lake City factory, with the first shipment of shields expected to be delivered in the coming weeks to Utah’s medical community. The four brands have come together in a unique way to make this possible, with tooling donated by Eastman, raw materials purchased by Goal Zero and by utilizing retrofitted Petzl headlamp headbands.

R3 Composites Corp. builds shower units for mobile hospitals

April 8, 2020

Pictured from left to right in front of a 4,400-ton compression press: Roy Potter, American Bath Group’s Aquatic SMC Plant Manager; Marc Hickman, R3 Composites Operations Manager; and Francisco Rojas, R3 Press Operator. Source | R3 Composites Corp.

R3 Composites Corp. (Grabill, Ind., U.S.) announces that it is manufacturing standalone shower units destined for mobile hospitals, for its customer American Bath Group. The first shipment will leave the R3 docks on April 8 bound for a popup hospital in an area hardest hit by the COVID-19 pandemic. R3 Composites is following the CDC recommendations for a safe work environment and benchmarking other essential manufacturing locations to ensure the company is doing everything they can to create a safe work environment while producing product to aid the frontline fight against COVID-19.

Spirit AeroSystems announces new cost-reduction measures in light of coronavirus

April 8, 2020

See full story here.

Gerber Technology brings together industry suppliers to increase production, availability of PPE

April 8, 2020

In response to the coronavirus outbreak, Gerber Technology (Tolland, Conn., U.S.) has created a Global PPE Task Force that has brought together more than 600 manufacturers, technology partners and industry coalition partners to make personal protection equipment (PPE) products available broadly around the world.

Building on their successful experience of converting Chinese manufacturers to produce PPE to address the COVID-19 mitigation plans in China, Gerber and its partners formed a network to scale the global production and to match supply and demand for critically needed PPE products. Gerber’s partners include leading industry companies and associations such as: AAFA, AAPN, Coats, Elevate Textiles, Fashion for Frontline, Henderson Sewing, Industrial Fabrics Association International, NCTO, SPESA, Suuchi and Zilingo.

Triumph Group converts manufacturing resources to produce PPE, medical equipment

April 7, 2020

Triumph Group (Berwyn, Pa., U.S.), whose Triumph Aerospace Structures business designs, develops and certifies aircraft structures including composites, has announced that it is using manufacturing resource to produce personal protective equipment (PPE) and components for oxygen distributors for first responders and local hospitals.

The Triumph Systems & Support site in Isle of Man is partnering with Nobel's Hospital to produce valves using 3D printers that are retrofitted on snorkeling masks and connected to oxygen distributors to create makeshift ventilator masks. The site is working with other local manufactures to produce approximately 650 valves per week.

The Triumph Systems & Support aftermarket repair businesses in Atlanta, Georgia and Hot Springs, Arkansas will aid in the production of nonmedical fabric masks used to reduce the spread of respiratory droplets to the face. These sites will provide the high-demand form of PPE for other Triumph sites as well as community partners.

Several other Triumph sites in the U.S. will produce 3D-printed face shields for first responders using approved design templates. The company’s facilities in Red Oak, Texas and Park City, Utah have the capacity to print approximately 1,000 units per week. The company is also exploring opportunities to print ventilator parts.

The Triumph Group Foundation is also expanding support for nonprofit organizations serving communities hardest hit by the coronavirus pandemic.

Composite Integration designs face visor prototype for U.K. health workers

April 6, 2020

Source | Composite Integration

Composite Integration (Saltash, U.K.), in collaboration with several colleagues from across the U.K., is using its production capabilities to accelerate the design of face visors, producing prototypes which have been functionally reviewed and accepted by NHS Plymouth.

All components have been procured from local U.K. sources, enabling Composite Integration to offer rapid supply to meet the growing demand. Production has started and Composite Integration is aiming to manufacture approximately 2,500 visors per week for key workers, including doctors, nurses, carers, shop workers and delivery drivers.

In addition, the company reports that it has introduced strict health and safety measures to protect its employees, families, customers and suppliers. Many of its employees are working remotely from home, reducing the contact levels internally and the main facility is working with a skeleton crew allowing it to fulfill customer requirements.

Hexcel takes cost-reduction steps including merger termination

April 6, 2020

Hexcel Corp. (Stamford, Conn., U.S.) reports that as its plants continue to operate and serve customers during the COVID-19 pandemic in accordance with applicable laws and regulations, the company is committed to providing a safe and secure workplace for its employees, instituting additional safety measures such as enhanced cleaning and sanitation procedures, social distancing protocols, and working from home for employees who can do so.

To mitigate the effect of current market conditions, the company has taken immediate steps to reduce costs including implementing a hiring freeze, restricting travel, scrutinizing all discretionary spending, curtailing capital expenditures and evaluating employment levels to align with lower customer demand.

Also announced on April 6, as a result of market uncertainty the company has terminated its previously announced merger of equals with Woodward.

Boeing suspends 787 operations in South Carolina

April 6, 2020

The Boeing Co. (Chicago, Ill., U.S) will temporarily suspend all 787 operations at Boeing South Carolina (BSC) until further notice, starting at the end of second shift on Wednesday, April 8. This impacts the Airport Campus, Emergent Operations, Interiors Responsibility Center South Carolina and Propulsion South Carolina.

“It is our commitment to focus on the health and safety of our teammates while assessing the spread of the virus across the state, its impact on the reliability of our global supply chain and that ripple effect on the 787 program,” says Brad Zaback, vice president and general manager of the 787 Program and BSC site leader. “We are working in alignment with state and local government officials and public health officials to take actions that best protect our people.”

BSC teammates who can work remotely will continue to do so. Those who cannot work remotely will receive paid leave for 10 working days of the suspension, which is double the company policy. After 10 days, teammates will have the option to use a combination of available paid time-off benefits or file for emergency state unemployment benefits. All benefits will continue as normal during the suspension of operations, regardless of how teammates choose to record their time. Pay practice details have been made available to all teammates.

During this time of suspension on the 787 program, Boeing will continue to conduct enhanced cleaning activities at the site and monitor the global supply chain as the situation evolves.

When the suspension is lifted, the 787 program will take an orderly approach to restarting production with a focus on safety, quality, integrity and meeting customer commitments.

Albany International temporarily suspends production at certain composites facilities

April 6, 2020

Albany International (Rochester, N.H., U.S.) reports that within its Albany Engineered Composites (AEC) segment, operations have been disrupted at certain facilities. In response to market conditions and in close coordination with its customer, Safran, the company is temporarily suspending production at its Albany Safran Composites facilities, which produce components for the LEAP aircraft engine, in Commercy, France; Rochester, New Hampshire; and Querétaro, Mexico. The lengths of the production suspensions may vary by facility, and the resumption of operations will be undertaken in coordination with Safran and in compliance with all local, state/provincial, and national guidelines or directives.

Additionally, the company has halted operations at one of its two AEC production facilities in Salt Lake City, Utah, after an employee at that facility tested positive for the coronavirus. The facility, which has a staff of about 70, is expected to be closed for up to two weeks as the employees from the facility self-quarantine and as the company conducts a thorough deep cleaning. There has been no impact to operations at the company’s larger Salt Lake City AEC production facility, which supports multiple programs, including the Lockheed Martin F-35, the Boeing 787, and the Sikorsky CH-53K.

Owens Corning temporarily curtails operations in some facilities

April 6, 2020

Building and industrial materials supplier Owens Corning (Toledo, Ohio, U.S.) reports that its operations and products have been deemed essential across the U.S. and global locations, as it manufactures products integral to essential areas such as infrastructure, energy, transportation and construction industries. In some countries, certain of its sites have been impacted by government directives.

According to Owens Corning, the pandemic has resulted in a slowing near-term demand environment in several global markets. The company will temporarily curtail operations at facilities with adequate inventory to meet near-term demand.

In addition, the company has implemented several enhanced operating protocols, including robust cleaning procedures, use of personal protective equipment, social distancing, employee health screenings, restrictions on business travel, and work from home requirements at all of its locations consistent with the guidance of the CDC, WHO, and local state and government mandates. In addition, the company has enhanced sick leave and other healthcare benefits for employees to provide additional assistance.

TPI Composites Inc. announces temporary reductions and suspensions of production at certain facilities

April 3, 2020

Global composite wind blade manufacturer TPI Composites Inc. (Scottsdale, Ariz., U.S.) has announced that it is currently operating its Chennai, India, manufacturing facility with a skeleton staff through April 15, 2020 and that it will temporarily operate its Matamoros, Mexico facility at reduced capacity beginning on April 3, 2020 through April 30, 2020. TPI also stated that it will operate its Izmir, Turkey manufacturing facilities at approximately 50% capacity during the first half of April.

TPI says its decision to temporarily reduce or suspend production at these manufacturing facilities is due primarily to certain applicable government-mandated stay-at-home orders in response to the COVID-19 pandemic. These temporary reductions and suspensions of production may last longer than TPI currently anticipates if the government-mandated stay at home orders are extended. TPI currently is operating its other manufacturing facilities at normal production levels, including its manufacturing facilities in China.

In addition, TPI has implemented a crisis management plan and measures focused on prevention, protection and the support of the public health system, and has eliminated non-essential travel, measures to restrict visitors to business essential personnel only, temperature scanning for individuals entering its manufacturing facilities, and work-from-home arrangements where possible. TPI also is providing on-going education and reinforcement of safe behaviors such as proper hand hygiene, cleaning and sanitizing and social distancing for its associates that continue to work on site.

Although TPI reports that demand from its customers remains strong, as a result of the uncertainty relating to the magnitude and duration of the COVID-19 pandemic, TPI is updating its financial guidance issued on February 27, 2020 for the year ending December 31, 2020 such that TPI now expects that Adjusted EBITDA for the year ending December 31, 2020 will be at the lower end of its previously announced range of $100 million to $125 million.

TE Wire & Cable factory remains open, many employees working from home

April 3, 2020

TE Wire & Cable LLC (Saddle Brook, N.J., U.S.), global manufacturer of autoclave thermocouples, reports that its factory is open, and the health and safety of its employees remain the company’s highest priority. TE Wire & Cable is following the latest directives as prescribed by the CDC as well as the high standards set by its parent company, Marmon Holdings Inc. Strict sanitation measures are in place, along with social separation guidelines within company facilities. It is TE Wire & Cable’s goal to continue to meet its customers’ demands during this time, though the company does anticipate that lead times will change with possible reductions in labor force.

The company has implemented a work-from-home policy for its staff, with a skeleton screw in the office employing social separation. The office and factory are on lockdown, meaning no outside visitors are allowed into the building. There will be no international or domestic travel for the company’s sales team; however, the company says it is fully equipped to communicate with customers via video conference, email or phone. The management team is monitoring the supply chain, and to date, the company says its raw material inventory remains at satisfactory levels.

Cobra International reports temporary production schedule changes to automotive business unit

April 3, 2020

Cobra International (Chonburi, Thailand) reports a temporary slow-down in customer demand in some areas of its business, such as automotive and watersports, and as a result, the company has implemented the following production schedule as of April 2, 2020:

- Cobra continues to run its production facilities for 4 days per week.

- A number of production lines within CAC (Cobra's automotive business unit) will be paused between April 6-30 due to the temporary production suspensions of European automotive OEMs. CAC will keep in close contact with its customers and suppliers during this period and can quickly resume production when demand shifts.

- Cobra will assess productivity and, if any other business areas show significant demand reduction, may temporarily shut down specific production lines for a period of time.

- Cobra is working closely with suppliers and logistics providers to minimize disruption wherever possible.

Cobra also reports that health and safety measures for its 2,400 employees have resulted in no recorded cases of COVID-19 at its factories and workspaces.

“... I would like to assure our customers, suppliers and associates that other than the changes to the manufacturing schedule as reported, it is very much business as normal at Cobra. We will also take this time to improve our operations, upskill our team and further develop our products and production technology ...” says Danu Chotikapanich, Cobra CEO.

Boeing to temporarily suspend Philadelphia-area operations in response to escalating COVID-19 pandemic

April 2, 2020

Boeing (Chicago, Ill., U.S.) is temporarily suspending production operations at its facilities in Ridley Township, Pa., U.S., in light of the company’s continuous assessment of the spread of COVID-19 in the region. This action is intended to ensure the well-being of employees, their families and local communities, and will include an orderly shutdown consistent with requirements of U.S. and global defense customers.

Boeing will suspend operations beginning at the end of day on Friday, April 3. The site includes manufacturing and production facilities for military rotorcraft, including the H-47 Chinook, V-22 Osprey and MH-139A Grey Wolf. Defense and commercial services work and engineering design activities are also performed at the site.

The suspension of operations will last two weeks, with return to work on April 20. During the suspension, Boeing will continue to monitor government guidance and actions on COVID-19 and associated impacts on company operations. The company will conduct additional deep cleaning activities at buildings across the site and establish rigorous criteria for return to work.

Philadelphia area employees who can work from home will continue to do so. Those who cannot work remotely will receive paid leave for the 10 working days, which Boeing says is double the normal company policy.

On March 23, Boeing announced a two-week suspension of Puget Sound operations.

C.R. Onsrud continues operations, supporting “essential” businesses

April 2, 2020

CNC machinery supplier C.R. Onsrud (Troutman, N.C., U.S.) is currently open and serving its customers. As a supplier to multiple companies which are classified as mission critical business for national security under Presidential Policy Directive 21, C.R. Onsrud is manufacturing new machinery, shipping parts to customers, and available via its support lines in order to keep its customers’ CNC machines in full operation at all times. As a business manufacturing equipment that enables the essential manufacturing of products currently in demand during this COVID-19 crisis, C.R. Onsrud is remaining in operation to support essential businesses that rely on its equipment and services to ramp up production of these items needed; such as hospital beds, aluminum processing equipment, plastics processing, medical equipment, emergency transportation vehicles, aerospace products, defense projects, and the wood products industry. C.R. Onsrud is following in accordance with the CDC and WHO workplace guidelines and has transitioned non-manufacturing support staff that can effectively work from home to remote support.

AZCO Corp. products used in manufacture of medical devices

April 2, 2020

Source | AZCO

AZCO Corp. (Fairfield, N.J., U.S.), which designs and manufactures modules and units used to feed, cut and place products, remains in operation during this time. The company says it is part of the supply chain of many machine builders who are considered essential businesses, including manufacturers of medical devices, diagnostics and treatments for the coronavirus.

AZCO units employed in the production of medical supplies include cut to length units used to produce masks, gowns and medical gauze & tape, a test strip cutter for diagnostic test strips, and a tubing cutter for medical tubing used in hospital applications.

Gougeon Brothers Inc. and business units continue operations

April 2, 2020

Gougeon Brothers Inc. (Bay City, Mich., U.S.) and its business units WEST SYSTEM, PRO-SET EPOXY, Entropy Resins and PRO-VAC USA play an essential role in the supply chain for products or services that are necessary for critical infrastructure sector companies to maintain operations. The company says it will remain operational while following safe workplace practices. Many of the company's team members are now working from home.

AAG launches LinkedIn group for fabricators to share ideas and designs for fighting coronavirus

April 2, 2020

When COVID-19 became an international pandemic, AAG (AXYZ Automation Group, Burlington, Ontario, Canada), noticed that many of its customers were eager to help in the fight against the virus by fabricating innovative solutions for PPE and other safety supplies but had no forum to share these ideas, designs and discussions.

As a result, AAG (AXYZ Automation Group), comprised of AXYZ Routers, WARDJet Waterjets, and CNCShop created an online group called Fabricators Fighting COVID-19 on LinkedIn. AAG is also connecting fabricators with members of the community for specific safety requests when possible.

Join the group here: https://www.linkedin.com/groups/12386421/

Robroy Enclosures meets needs of medical suppliers

April 2, 2020

Robroy Enclosures (Belding, Mich., U.S.), manufacturers of Stahlin Enclosures brand of fiberglass enclosures, and Attabox polycarbonate enclosures, has quickly adapted its operations to ensure its ability to meet the needs of suppliers in the healthcare industry.

According to Craig Mitchell, president of Robroy Enclosures, “We have been successfully responding to urgent requests for medical application rush jobs; most recently, critical needs from a wireless infrastructure supplier to healthcare customers, as well as a manufacturer of patient monitoring systems.”

Mitchell notes that although Robroy Enclosures has enacted safety protocols to protect the health of its own workers, the company's ability to produce its own bulk material formulations and to mold and customize its enclosures within one, fully-integrated facility, provides the flexibility to help address the product needs of suppliers within the healthcare community.

Robroy Enclosures offers the most extensive selection of non-metallic enclosures available for meeting the needs of diverse industries, interior and exterior applications, appealing aesthetics, and physical property performance standards including NEMA 4X and NEMA 6P integrity.

Henkel donates around 50,000 liters of disinfectant

April 2, 2020

Source | Henkel

As part of its global solidarity program in the fight against the coronavirus, Henkel (Düsseldorf, Germany) has announced that it will provide production capacities at short notice in order to produce disinfectants. Within one week, the company converted a production facility at its Düsseldorf site and produced the first 25,000 liters of hand disinfectants. Henkel will donate them to surrounding hospitals and public institutions. Next week, the company will continue the production and will produce the same amount of disinfectant.

With this week’s production alone, Henkel expects to be able to cover the needs of the major Düsseldorf hospitals and public institutions for the coming weeks. Henkel also took into account the demand from the vicinities of the 15 German sites. Delivery and distribution will be organized in close coordination with the local health authorities.

Henkel's solidarity program also includes a donation of €2 million to the COVID-19 Solidarity Response Fund launched by the WHO and the United Nations Foundation as well as to other organizations, and a donation of 5 million units of personal and household hygiene products.

Anisoprint provides free 3D-printed tools, jigs, fixtures to manufacturers

April 2, 2020

Source | Anisoprint

As some suppliers remain closed due to the coronavirus pandemic, Anisoprint (Moscow, Russia), manufacturer of 3D printers that print composites with continuous fibers, is providing 3D-printed composites parts such as jigs, fixtures and tools free of charge to manufacturing companies that continue to operate but have faced supply chain disruptions.

“Our technology can help replace traditional tools, jigs and fixtures with the 3D-printed composite ones. We have significant experience in producing composite parts for manufacturing companies and we definitely would be happy to support [manufacturers] now, during this crisis," says Fedor Antonov, CEO of Anisoprint.

LIFT, IACMI donate PPE equipment to Detroit health clinic

April 1, 2020

Source | LIFT

LIFT (Detroit, Mich., U.S.) and IACMI – The Composites Institute (Knoxville, Tenn., U.S.) have donated supplies of personal protective equipment (PPE) to nearby the Community Health and Social Services (CHASS) Center in Detroit in support of the fight against coronavirus.

Together, the institutes donated 600 safety glasses, 1,400 nitrile gloves and 60 Tyvek lab coats.

“This material will go a long way in keeping our staff safe as we fight this virus here in Southwest Detroit,” says Felix Valbuena, MD, CEO of Community Health and Social Services (CHASS) Center. “We appreciate both LIFT and IACMI and everything they and their networks are doing to keep our community safe and healthy.”

Solvay partners with Boeing for COVID-19 face shields

April 1, 2020

Solvay (Brussels, Belgium) is supplying high-performance, medical-grade transparent film to Boeing for its production of face shields. Boeing approached Solvay due to its experience in the use of advanced composite and adhesive materials on multiple commercial and defense programs.

Manufactured by Solvay's Ajedium Films business, the thermoplastic film will be used by Boeing in the production of thousands of face shields critically needed by hospitals and medical workers in the U.S. to protect them from COVID-19. The film will be manufactured using Solvay’s medical-grade Radel polyphenylsulfone (PPSU) or Udel polysulfone (PSU), two transparent specialty polymers widely used for medical devices because of their ability to be sterilized and withstand aggressive disinfectants.

“We are honored to bring our product expertise to our customers in this time of crisis,” explains Jeff Hrivnak, healthcare global business development manager for Solvay Specialty Polymers. “Boeing is rising to the occasion by providing more durable, face shields now in critical demand for our heroic healthcare workers, and we are proud to help make that possible.”

Further product and contact information are available on Solvay’s dedicated page on COVID-19 emergency production.

ATLAS Composite Technologies Ltd. remains open, providing face mask components to NHS

April 1, 2020

ATLAS Composite Technologies Ltd. (Ilkeston, U.K.) reports that it continues to remain open while following the latest government guidance on safe working practices and supporting as many employees as possible in working from home.

The company says that as a supplier for the motorsport, aerospace, defense and automotive industries, it has experienced a downturn in several of its business streams while defense and aerospace continue to demand deliveries, particularly in the defense market.

ATLAS says it is continuing to support its clients and to look into other programs where manufacturing support may be required. In addition, the company is working to support the National Health Service (NHS) through provision of components for face masks.

Altair offers extended licenses, free training to help companies work remotely

April 1, 2020

In response to the crisis and the increasing demand for remote operations, engineering software company Altair (Troy, Mich., U.S.) say it is enabling its customers to move existing licenses from on-premise servers to hosted servers utilizing Altair Hosted HyperWorks Units (HHWUs) with no additional fees or charges.

With these capabilities, customers are able to:

- Work from anywhere without overloading corporate VPN servers or drilling a hole into the firewall for license access.

- Secure data with prevailing security policies on the device of choice as the software is only requesting a license on a secure network channel.

- Reduce IT overhead of maintaining on-premises license servers (reduced cost of hardware) and supporting them.

- Improve ease of access and execution of Altair software from anywhere/everywhere and on public cloud infrastructure.

Additionally, customers have free access to an increased number of online trainings, eLearning courses, and eBooks through Altair.

For earlier coronavirus coverage in the composites industry, see “Composites industry response to the coronavirus pandemic, Part 1.”

Related Content

Arch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read MoreEDM, Laser Micromachining and More at GF Medical Demo Center

At GF’s Medical Center of Competence, the company shows off EDM and laser features that could make a large impact on medical manufacturing — and elsewhere.

Read MoreYCM Alliance Hits IMTS

YCM Technology has joined with other like-minded machine tool manufacturers to take a solutions-based approach to manufacturing.

Read MoreModern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)