Meaningful Growth Requires Cost Tracking, Traceability and Scalability

In order to achieve the owners’ vision of using their shop as part of a community-focused nonprofit, Hastreiter Industries first had to achieve enough ERP sophistication to grow.

Founded in 1988, Marshfield, Wisconsin-based Hastreiter Industries worked largely under the radar until 2018, when it leaped into the spotlight by winning Modern Machine Shop’s Top Shops award in the category of Human Resources as well as a featured position on the magazine’s cover.

However, the road from small shop to Top Shop was not so cut and dry. A vision of expansion required an overhaul of long-trusted and organically developed systems of enterprise and resource management. RealTrac’s ERP platform has enabled the company to achieve its goals and make an impact on the wider community.

A Socially Conscious Company

For 28 years, Hastreiter focused on CNC turning with only a small amount of support milling capabilities. Owners Ken and Sondra Hastreiter wanted to use their business to make an impact in society, which led them in 2013 to begin donating 50% of the company’s net profit annually.

Wanting to make an impact beyond philanthropy alone, they developed a plan to establish a nonprofit designed to mentor people coming from challenged backgrounds. This nonprofit would provide training in interpersonal and life skills, and the machine shop would be used to teach participants a trade skill, thus enabling them to stand on their own both personally and economically.

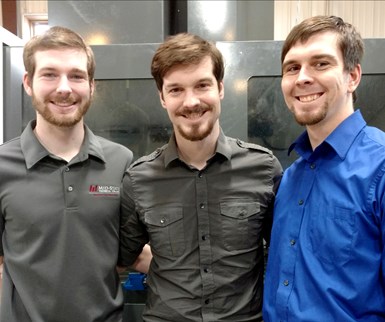

Brothers Kody, Kylan and Keegan Hastreiter (left to right) helped grow the company from small shop to Top Shop.

The problem was that Hastreiter Industries was too small to provide sufficient work and training capacity to make this plan a reality. As Ken and Sondra’s sons joined the company in 2016, a path forward was determined.

Five-Axis Work Provides the Opportunity to Adopt an ERP System

An internal review showed that while Hastreiter’s CNC machines were sufficiently advanced, the company was lacking on the software front. The shop had solid accounting and shopfloor performance, but its processes were not scalable for growth. The way this small business naturally functioned simply did not meet the requirements it would need to successfully run as a larger company. Hastreiter needed to come up with new systems to handle expansion without losing performance from the increased complexity in business operations.

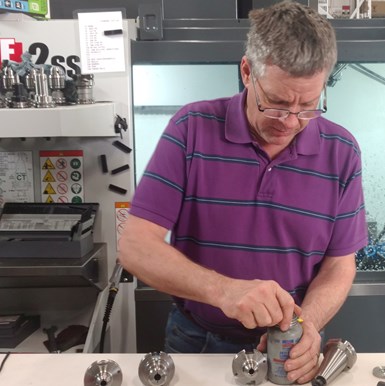

Ken Hastreiter started Hastreiter Industries in 1988 and never foresaw his sons joining the family business. Their addition to the team occurred in 2016 with the new vision of impacting the community positively.

In late 2016, growth came when the shop reentered the aerospace market via five-axis milling. As powerful and efficient as five-axis machining is, Hastreiter realized it needed an equally capable method of tracking performance and maintaining its process evolution.

Hastreiter Industries started an in-depth evaluation of eight different ERP systems. Some of the criteria Hastreiter had for its ERP system included the ability to:

- Track times and costs of individuals jobs efficiently,

- Lay the foundation for gaining ISO 9001 and AS9100 certifications, and

- Gain full data visibility and live shopfloor status.

Hastreiter settled on RealTrac, implementing it beginning in 2017. Gone were the days of pen, paper and spreadsheets as the company began formalizing its quoting system through the new software. Once a job was won, it would go directly from quote to shop floor where machinists would clock in and out of each operation. Hastreiter was then able to use RealTrac to track the value, on a per job basis, of jumping into five-axis machining. The RealTrac system provided good data — a critical component for making decisions — which is why an overall cost summary would be printed and analyzed after each job, the company says.

Meeting the Information Needs of Both Machinists and Managers

As a job shop producing low- to medium-volume machined parts, a job could take Hastreiter two hours or a few weeks to finish. Before RealTrac, the company had no way to efficiently track and compare the actual time in production versus the amount of time quoted. Additionally, when operations take as little as a few minutes to complete, having an operator take more than a few seconds to enter data would be too costly. RealTrac’s Shopfloor client — referred to by shop staff as “blue car” because of its desktop icon — has had no issues keeping up with Hastreiter’s machinists, the company reports.

While lacking CAM and ERP software three years ago, Hastreiter’s rapid upgrades, including the adoption of RealTrac ERP software, has since helped to launch the company to the level of sophistication necessary for expansion.

The Shopfloor client isn’t just for operators; it also provides live shopfloor visibility for Hastreiter’s managers. “When Hasteiter was smaller, everyone just kind of knew where everything was at any given moment,” says Vice President Kylan Hastreiter. “That isn’t the case anymore, as we’ve added a second building and a lot more people.”

The RealTrac Shopfloor screen displays the name of every operator and programmer, what job they are currently working on, as well as color-coded job statuses for quick information digestion. Primarily, this provides the ability to give feedback to operators about their personal performance.

“When Hasteiter was smaller, everyone just kind of knew where everything was at any given moment. That isn’t the case anymore, as we’ve added a second building and a lot more people.”

Previously, machinists had no live feedback on the target time per operation. Use of RealTrac has also provided machinists with estimated times on the job’s router, including programming, setup and operating times. Hastreiter finds this to be an important tool that pairs well with the relatively decentralized structure of the company. This equips machinists with as much information and as many tools as possible to allow them to work independently.

Hastreiter Industries did not have a formal router before RealTrac. Machinists were given prints that included purchase order and line number, quantity, material and finishing requirements. The fact that the company had a small, experienced crew doing low-volume repeat work meant that machinists simply learned what all the operations were by heart. However, it was obvious that this needed to change as Hastreiter added new customers and employees. The changes RealTrac has enabled have helped to streamline communication, thereby reducing growing pains.

A Formal System Doesn’t Have To Be Stiff

Before long, RealTrac was implemented across other areas of the company, such as material inventory and tracking, formalizing dozens of processes as a result. The bigger a company gets, the more formal its processes must become. But while the stereotype is that the more a structure formalizes, the more stiff that system becomes, that has not been the case with Hastreiter.

Making a difference in the local community, Hastreiter hosts 150 eighth graders on a tour of Hastreiter Industries as part of the Heavy Metal Tour put on by the Central Wisconsin Metal Manufacturers Alliance (CWIMMA).

“The main beauty is that while we’re embracing it 100%, it embraces us back,” Kylan Hastreiter says. “We don’t have to bend over backward to make it fit us; it’s a pretty easy system to use.”

With Realtrac as its business system, Hastreiter has more than quadrupled in personnel since 2016, grown its capabilities in partnership with Okuma and Morris Midwest, and recently upgraded to a 42,000-square-foot facility. Implementation is said to have posed minimal strain, allowing the company to take growth at its own pace with scalable systems. Hastreiter will also be getting its ISO 9001 and AS9100 certifications soon. Supported by a dependable shop management system, Hastreiter Industries has become well-equipped for the continual growth needed to hit its goals of impacting its community.

Related Content

Finding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreBusiness Award Winner Gains Traction on Strategic Vision

KLH Industries joins the 2022 Top Shops Honors Program with a renewed sense of identity, a new leadership team and new tools for driving growth.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreConferences at a Glance - Tuesday

A streamlined itinerary of Tuesday's conferences, including Modern Machine Shop's Top Shop Awards ceremony, at your fingertips. Find out more about today's conferences below.

Read MoreRead Next

Top Shops Winners Talk Technology, Tactics

Successful machining businesses implement effective processes and strategies both on the shop floor and in the front office. Recent chats with representatives from this year’s award-winning Top Shops shed light on some approaches they have leveraged to their advantage.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)