CAMplete Releases TurnMill V9

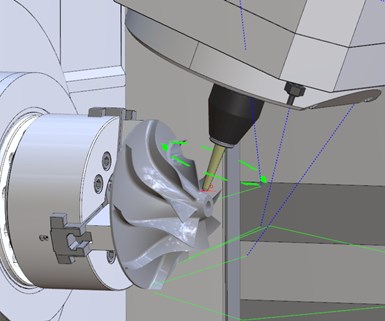

Dedicated to Nakamura-Tome’s line of turning centers, version 9 of CAMplete’s TurnMill software includes enhancements to 3D rendering, simulation and postprocessing.

Dedicated to Nakamura-Tome’s line of turning centers, version 9 of CAMplete’s TurnMill software includes enhancements to 3D rendering, simulation and postprocessing. The software is designed for combining output from all of a shop’s CAM systems to create multitasking programs that are verified and ready to run on the lathe.

Among the 3D viewing improvements are:

- Realistic rendering effects such as metal shading, reflection modeling, advanced lighting modeling and edge drawing, which all help highlight important geometric features;

- 3D space mouse support that works directly with the driver control panel user interface; and

- Hardware driver support for a wider variety of video cards, allowing users to run TruePath effectively on their existing laptops.

Among the improvements made to TurnMill’s simulation capabilities are:

- Collision Mode Pausing and Interpolation View allowing the user to precisely examine all points of motion, even between programmed points; and

- Improved 3D collision visualization to more easily see the interference of the 3D geometry during interactive machine jogging.

The revamped postprocessing engine is said to provide more flexibility for use with Mastercam and GibbsCAM. Intelligent decision-making algorithms limit wasted motion for better efficiency, according to CAMplete.

Related Content

-

Fearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

-

CAD/CAM System Requirements: An Overview

CAD/CAM programs are among the most demanding kinds of computer software. Smooth operation requires careful consideration of computer specifications.

-

Improve Machining Efficiency Through Digital Twin Simulation

Full simulation of a machining cycle using digital twins can not only identify crashes before they happen, but provide insights that enable the user to reduce cycle times.