Aerospace, Energy Machining Hub Supports Diverse Needs

Surrounded by defense contractors and original equipment manufacturers (OEMs), this GF Machining Solutions facility provides technology and expertise for applications ranging from specialty blade cutting to laser texturing.

Specialized airfoil cutting machines attracted significant attention at the April 25 opening of GF Machining Solutions’ new Aerospace and Energy Center of Competence in Huntersville, North Carolina. However, the overall takeaway was the value of bringing to bear a diverse range of capabilities and perspectives to address any given challenge, particularly those associated with manned flight.

That point was driven home the night before at the opening reception at the Carolinas Aviation Museum in Charlotte. There, attendees had dinner under the wing of the Airbus A320 made famous by the 2009 “miracle on the Hudson,” when Captain Chesley “Sully” Sullenberger guided U.S. Airways Flight 1549 safely past New York City skyscrapers to plunge tail-down and nose-up into the icy river after an act-of-God bird strike on takeoff. Testimony from survivor and guest speaker Dan Vinton made clear that along with Captain Sully’s heroism, keeping everyone alive that day required similar focus and discipline from the entire flight crew, and from New York and New Jersey first responders.

It can be argued that even more people contributed to that safety behind the scenes. Remarkably intact despite its shredded turbines and battered fuselage, the plane itself stood testament to the engineers and machinists in the audience who work daily to make modern flight the safest form of travel. This was also the audience for the next days’ demonstrations and seminars covering all manner of highly specialized aerospace machining technology.

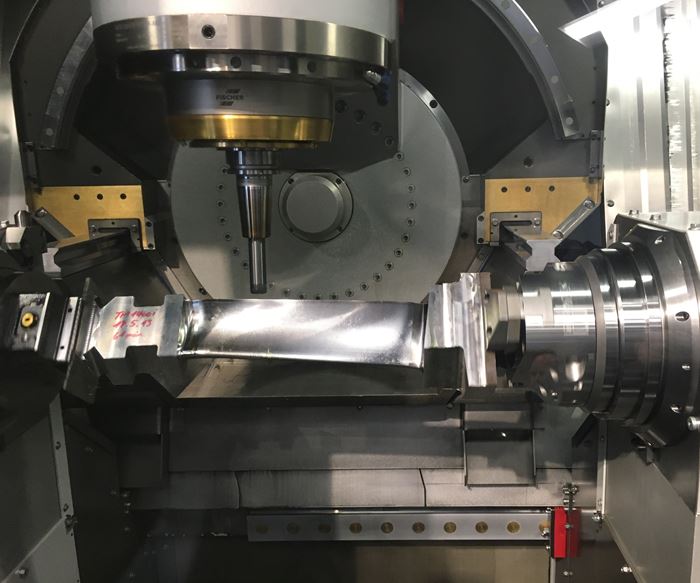

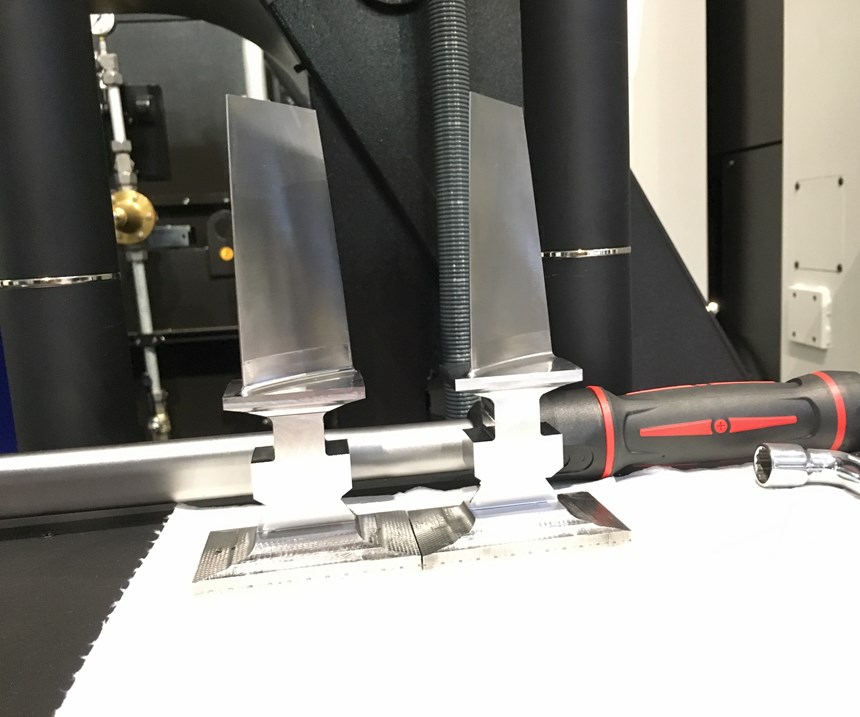

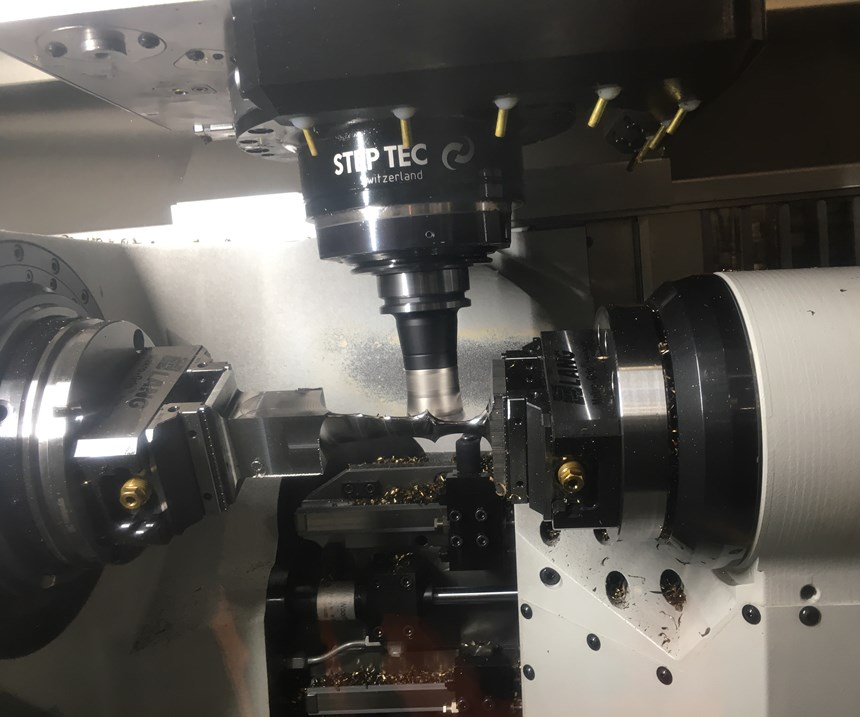

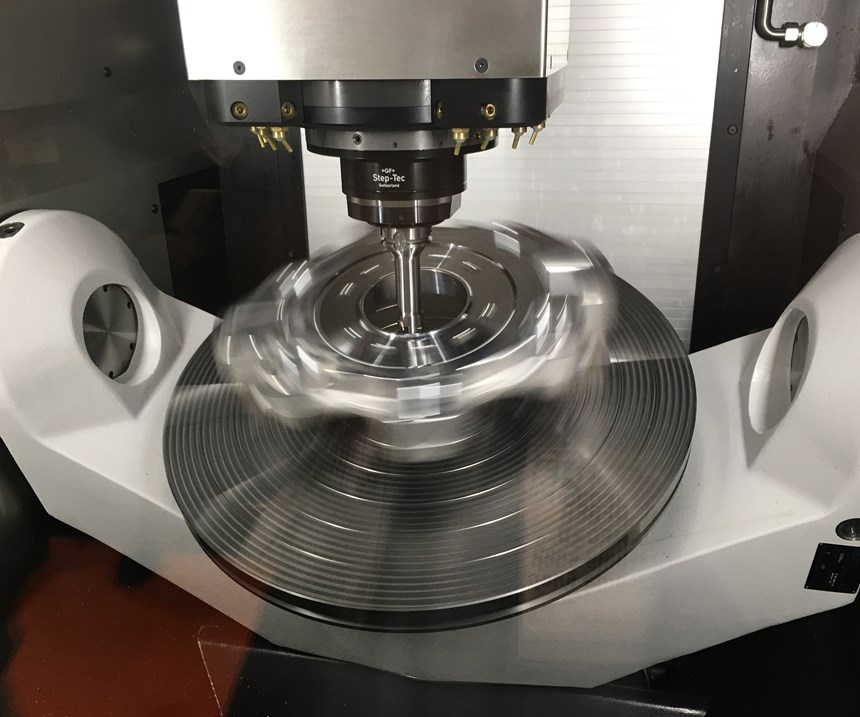

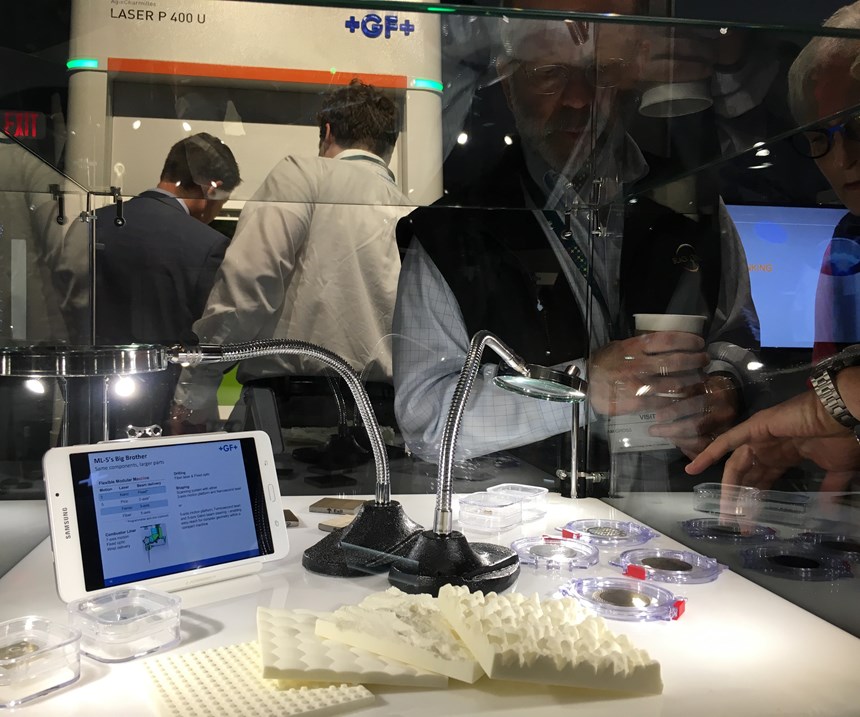

Five- and six-axis machines from Liechti, a Swiss specialist in five- and six-axis airfoil milling acquired three years ago by GF, were a particular highlight. Demonstrating the facility’s focus on energy industry turbine components as well as aerospace blades, these specialty systems are now housed alongside Mikron three- and five-axis machining centers; laser-texturing machinery; Microlution laser-cutting and drilling equipment; AgieCharmilles wire-cutting and die-sinking electrical discharge machines; and System 3R standardized workholding and automation. Well-positioned amid defense contractors and various large OEMs, the new facility also consolidates service and applications expertise. Already, closer collaboration among brands has given rise to the turbine group, a 21-person team dedicated to addressing challenges with those specialty applications.

As a global company with a broad line, GF Machining’s commitment to these specific markets is telling. Although he emphasized the continued importance of the automotive, medical, information technology and other sectors, company president Pascal Boillat says aerospace has been particularly important to the company’s growth (revenue has reportedly climbed from $900 million to more than $1 billion in two years). The company’s broader goals also evidence the strength of this market. These include growing the Liechti brand 20 percent by 2020, an effort that will be facilitated in large part by the construction of a new 400,000-square-foot production facility for spindles and milling equipment in Biel, Switzerland. The company is also pushing further digitalization, as evidenced by its recent purchase of a machine-connectivity software developer. The company’s U.S. headquarters is in Lincolnshire, Illinois, and it also maintains a facility in Holliston, Massachusetts.

Related Content

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

How to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

-

Toolpath-Level Machine Monitoring Improves Aerospace OEE

Machine monitoring software that records historical efficiency to the toolpath level helped aerospace manufacturer Leesta improve its OEE by ten points.

.png;maxWidth=300;quality=90)