Ceramic Turning Grade Offers Alternative to PcBN

Kennametals’ KYHK15B grade reportedly provides greater depth of cut capabilities than PcBN inserts when machining hardened steel, high-temperature alloys and cast iron.

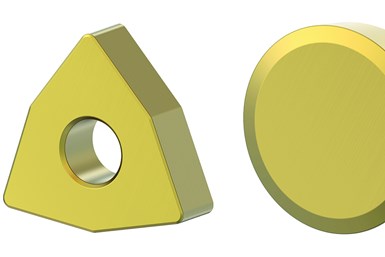

Kennametal introduces its latest ceramic turning grade, KYHK15B, designed to deliver increased productivity and lower cost per edge in hard turning operations. The new grade reportedly provides greater depth of cut capabilities than PcBN inserts when machining hardened steel, high-temperature alloys and cast iron, as well as maximum tool life and wear resistance for demanding turning applications.

According to the company, KYHK15B provides excellent edge stability, high chipping resistance and a physical vapor deposition (PVD) gold coating that makes identification of wear progression very easy. KYHK15B is designed to be an economic alternative to PcBN inserts.

KYHK15B builds on an existing line of high-performance ceramic turning grades, providing manufacturers a productive solution for hard turning applications even in varying or heavy depths of cut.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Buying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

-

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

.png;maxWidth=300;quality=90)