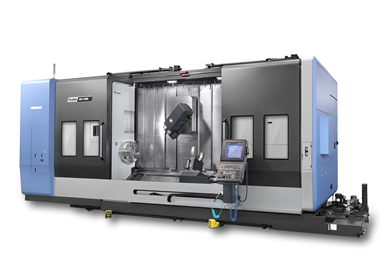

Doosan Puma SMX5100L Turn-Mill Has More Chuck Sizes

The Doosan Puma SMX5100L is a twin-spindle, multi-tasking turn-mill center designed to complete complex parts in a single setup, with chuck sizes available in 15, 18 and 21 inches.

Doosan Machine Tools’ Puma SMX5100L is the latest addition to the company’s twin-spindle, multi-tasking turn-mill centers. The Puma SMX Series is specifically designed to complete complex parts in a single setup.

The Puma SMX5100L is the largest machine in the SMX Series, with a maximum turning diameter of 32.7" and maximum turn length of 120.1". Chuck sizes of 15", 18" and 21" are available for the standard main turning spindle, which features a 49.6-hp built-in motor that spins at 2,400 rpm. Also available is an optional gear box spindle that rotates at 1,500 rpm and outputs 4,198 Nm (3,096 foot-pounds) of torque for heavy duty applications.

A 49.6-hp motor rotating at 10,000 rpm powers the B-axis milling head, which features a Capto C8. The company says the roller gear cam mechanism that drives the B-axis is backlash-free and highly rigid, outputting B-axis torque of 2,700 Nm (1,991 foot-pounds).

According to the company, the machine is suitable for aerospace applications, including landing gear components, and housing for large shafts like those found in the agriculture and oil industries.

The Puma SMX machines are designed to have rigid machine construction. Strategically placed sensors throughout the machine offer real-time measurement and adjustment of the axes to minimize thermal deformation. For added stability and speed, three rows of cross-roller linear guideways support the Z-axis in which the carriage moves.

The Puma SMX line also comes standard with ergonomic features that improve operator convenience and efficient maintenance, including FANUC five-axis machining software offering 600 blocks of look-ahead and improved servo acceleration/deceleration.

Related Content

-

Controlling Extreme Cutting Conditions in Large-Part Machining

Newly patented technologies for controlling chatter and vibration during milling, turning and boring operations promise to drastically reduce production time and increase machining performance.

-

IMTS 2022 Review: Attention to Automation Extends Beyond the Robot and the Machine

The advance toward increasingly automated machining can be seen in the ways tooling, workholding, gaging and integration all support unattended production. This is the area of innovation I found most compelling at the recent International Manufacturing Technology Show.

-

How to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)