Hexagon's NCSIMUL 2021 Eases Detection of Rest Stock on Large Parts

The 2021 release of NCSIMUL digital twin software from Hexagon is said to improve CNC program quality through automatic predictive analysis.

The 2021 release of NCSIMUL digital twin software from Hexagon is said to improve CNC program quality through automatic predictive analysis. The software builds a virtual version of the real-world machining environment to avoid errors, decrease setup times and switch CNC programs between machines.

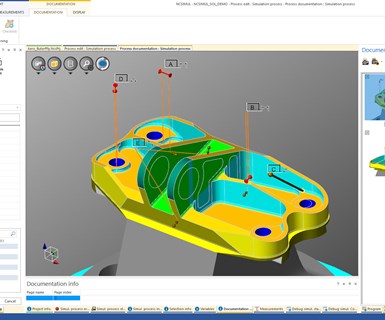

The software can now detect excessive material and show a solid comparison between the CAD/CAM models or previous cut stock and the simulated model. Among other benefits, the comparison function is said to help detect unwanted rest stock on large parts.

Integrated to NCDoc, the Dimensioning function creates control instructions for operators during the CNC process, defining a dimension checklist with user-defined tolerances, automatically defining the minimum measurement needed for each cut, generating a comprehensive view for the programmer and operator on the 3D simulation, and working with the NCDoc documentation template.

A new set of options quickly evaluates tools that can benefit from air cutting optimization with the “out of material working time” in the sequence list. This also works with the NCDoc documentation template and enables customization of stock nearness values for each sequence.

For setup editing, users can now merge fixtures, parts and rough stock elements from one or more CAD files read in NCSIMUL. The software creates simple geometric rough stock (either cylinder or cubes) and an automatic part envelope.

Improvements to mill-turn ease tooling management for Esprit and TopSolid CAM interfaces. With a “configuration interface file” associated to each digital twin, it is now possible to define the mapping of tool assembly positioning (station number, turret and orientation) between the CAM system and NCSIMUL.

For cutting tool wear simulation as defined in the tool magazine, NCSIMUL can now run the simulation for tools either “fresh out of the box,” or “worn down.” User-defined values apply for each cutting tool, and the system can check if a worn tool will generate alarms or collisions with unwanted rest stock material.

Related Content

-

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

-

When to Use Custom Macros With a CAM System

Custom macros can offer benefits even when using a CAM system to prepare programs – but must be implemented with the right considerations.

-

TTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.