Lean No Less Important

Lean manufacturing shouldn’t become lost in the shuffle of today’s emerging part-production technologies, strategies and approaches.

The Industrial Internet of Things (IIoT), additive manufacturing and collaborative robotics are emerging technologies that will change the nature of how manufacturers make parts. In a growing number of instances, they already are changing the nature of how manufacturers make parts. That’s why it is important that we cover these topics in our magazine, this blog, our various social media channels and so on.

That said, the concept of lean manufacturing should remain at top of mind for all parts producers out there. In fact, I plan to revisit this topic in a story for our July issue, describing how a shop’s efforts in cultivating a lean culture is enabling it to grow and win a greater amount of aerospace work.

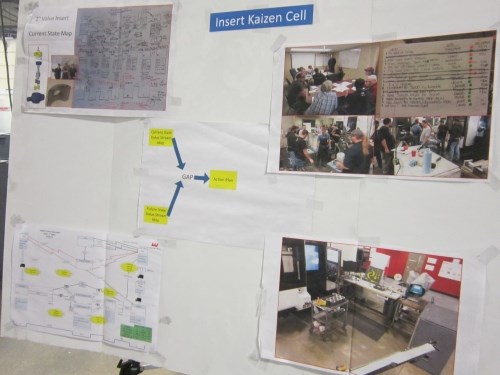

The title of this article might be something like “What Comes After 5S?” Many shops start their lean journey by implementing 5S workplace organization tactics, as did the shop I’m hoping to profile. However, I’d like this article to describe the next steps after 5S as it worked to establish its lean-manufacturing mindset and culture of continuous improvement.

In addition to appearing in our magazine, the story will be added to our website’s Lean Manufacturing Zone, which contains stories about other machining facilities that have made a lean transformation. For example:

- This one explains how a contract shop leveraged lean as a means to help it manageably control growth.

- This one describes how a job shop can integrate lean manufacturing into its DNA.

- This one describes what an A3 problem-solving process is all about and how an industrial equipment manufacturer uses it.

- And this one offers an overview of what 5S is all about.

Related Content

-

10 Lean Manufacturing Ideas for Machine Shops

In addition to the right mix of traditional strategies, a lean manufacturing toolkit can make high-mix, low-volume machining faster, more predictable and less expensive.

-

What Are the Limits to Make-to-Order Manufacturing?

Automated storage and retrieval system maker Modula produces a product with 2,000 parts and hundreds of variations that has to be completed within a customer’s site. Here is a picture of what is possible in making a product tailored to the customer.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)