Mastercam Highlights Design Tool Updates

Mastercam has added several enhancements to its Design software, including hole recognition, updated Note capabilities and geometry modification through mouse movement.

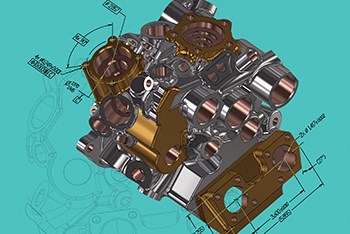

Mastercam is known for precision NC programming, but it also delivers a suite of design tools aimed at getting parts on and off the machine as quickly as possible. Its modeling tools include 3D surfacing and solids as well as hole-filling, direct-editing without a solids history, geometry repair and more.

Mastercam says its Design software streamlines and simplifies modeling and editing geometry. It is designed to support advanced geometry creation, including solid and surface modeling, hybrid machining, NURBS curves and surfaces, 2D and 3D associative dimensioning, surface extension, blending, trimming, splitting, variable filleting and hybrid modeling.

Recent Mastercam Design Solid Enhancements

Mastercam Design can recognize hole geometry — including intersecting and non-conventional holes — in solid bodies with no history. Once Mastercam discovers these holes, expanded options can be used to save custom holes to a template for future use. Users can use Mastercam’s Add History function to detect complex holes in solid bodies by selecting hole operations to find all holes within the range of minimum and maximum radius values that are entered. Mastercam creates an operation for each unique detected hole style.

Recent Mastercam Design Wireframe Enhancements

Modifying geometry by dragging a mouse is now available for Trim to Entities, Fillet Entities and Chamfer Entities functions. As users drag the mouse, Mastercam performs the function on the wireframe entities the mouse encounters. Mastercam now also has the ability to incorporate DrillPt functionality into small arcs.

Other Notable Mastercam Enhancements

Mastercam enables users to create text for notes and labels by adding many of the capabilities of the Create Letters function into the Note function. Note’s redesigned function panel is designed to give users improved usability, more options and increased control.

Other Mastercam Design improvements:

- Two new flowline functions, Edit UV and Reflow UV, can be used to analyze and modify the UV direction on surface models to more effectively utilize the flowline milling toolpaths.

- Ability to mirror geometry about both the X and Y-axes in one operation.

- Ability to draw a window to select multiple faces when users wish to change the color of a set of solid faces.

Related Content

-

Integrated CAD/CAM Promotes Process Efficiency, Traceability

High-requirement markets are not only searching for good parts — they're searching for proof of good parts. CAD/CAM software can help.

-

How Integrated CAD/CAM Transforms Inventions Into Products

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.

-

Building A Powerful Bridge from the CAM Programmer to the Shop Floor Operator

SolidCAM for Operators provides a powerful bridge from CAM programming to the shop floor to best streamline the machine shop process with its CAM part simulation. It provides a clear picture to the operator for setup and prove-out, enables minor G-Code changes and avoids crashes, broken tools and scrapped parts.

.JPG;width=70;height=70;mode=crop)