New Metalworking Products from Modern Machine Shop, Dec. 29, 2020

The latest technology from Vision Engineering, Tormach, Exact Metrology, Sunnen Products Company, and Velo3D

Vision Engineering Releases New High-End Measurement Systems

Vision Engineering’s LVC200 and Plus variants offer quick, accurate measurements for large components and multiple small components.

Vision Engineering broadens its LVC automated video measurement system range with the LVC200 and higher-specification Plus variants. The company recommends these systems for measuring large components or multiple small components swiftly and accurately.

The LVC range offers a choice of measuring capacities and fully automated movement in all 3 axes, making component measurement faster. The system is pre-programmable or can be joystick-driven for quick, one-off measurements. Users can create programs with non-stop measurement routines and built-in magnification changes, as well as use them to measure multiple components on the stage in a single operation.

Different stage sizes include an 8” x 6” x 8” stage for the LVC 200 and LVC200+, with the larger LVC400 sporting a 16” x 12” x 8” stage.

The LVC series now features 5MP or 6.4MP cameras, 6.5:1 or 12:1 motorized zoom with a 700x magnification range and granite and aluminum bases that enhance stability and precision. The Plus version also increases the field of view for faster measurement. LVC supports using a touch probe in all three axes for a wide range of industrial measurement applications, including precision machining, casting, plastic molding, electronics and medical devices.

LVC uses M3 software, which offers a rich suite of measurement functions that include advanced video edge detection, easy reporting and data export, DXF overlays and profile fitting.

Vision Engineering’s customers report that LVC is ideal for acquiring fast, accurate measurements and is intuitive for non-specialists.

Tormach 8L Lathe Promotes Affordable CNC Turning

Tormach’s new 8L Lathe offers a capable, compact CNC turning machine for shops and individuals on a budget, with PathPilot software and a unique 5C spindle.

Tormach Inc.’s 8L Lathe, is a compact CNC machine that can fill a variety of turning needs. The company promises the machine is rigid enough to cut plastic, stainless steel and titanium, and says its 5C spindle accommodates parts up to 1” diameter – which it believes should meet the needs of most lathe users. If users need to machine pieces up to 8” in diameter, they can add a three- or four-jaw chuck to cut the stock.

Like wtih all Tormach CNC machines, PathPilot software will control the 8L Lathe and allow users to leverage conversational lathe programming, do rigid tapping and use built-in Dropbox support for transferring programs.

Tormach’s 8L uniquely offers a 1.5 hp (1.11 kW) spindle that runs at 180-5,000 rpm. It already comes with the machine in a fully assembled enclosure as part of the base model, but the footprint remains small (26 in. x 50 in.), and the lathe itself is attached to a hand-scraped 140-pound cast base.

The company also says the travels on the 8L are impressive for its compact size, with a maximum workpiece length of 10” with the tailstock and an X-axis travel of 4.5” that allows users to machine parts that fully utilize the 8” swing. The stepper motors on the X and Z axes provide a feed rate of 150 ipm (3.8 m/min).

“We are excited to introduce this new lathe to the market,” says Cory Bailey, Tormach’s product engineer. “Tormach was founded on the idea of bringing cost-effective and capable CNC equipment to market and this one provides users with everything needed to face, turn, bore, groove and thread.”

Exact Metrology To Distribute PolyScan XL Surround Scanner

Exact Metrology is now distributing Polyrix’s PolyScan XL line of Surround 3D Scanners, which function while motionless and require no data alignment targets.

Exact Metrology is now distributing PolyScan XL. These scanners, part of the Polyrix PolyScan Surround 3D Scanner family, are motionless by design during the inspection process. Their unique calibration avoids the need for data alignment or sticker targets, and multiple baselines increase accuracy when measuring points.

The PolyScan XL6 is designed to measure parts up to 1,600 mm, combining 12 cameras and 12 projectors to provide 210 effective scanning units. The companies recommend it for medium-to-large aerospace castings and automotive sheet metal components. They also say the scanner completes part inspections in only six minutes, and the surround design, simplicity of automation and safety for operators make integrating it into a production line easy.

PolyScan XL8, the larger version of XL, is designed to measure parts up to 2,000 mm. It combines 16 cameras and 16 projectors to provide 376 effective scanning units.

Surround Scanning stems from the R&D Polyrix has done on software development since its foundation in 2005. The PolyScan Control Center (PCC) manages data acquisition from all scanning units to generate 3D models. Furthermore, PolyScan operation is made easier by the simple interface of the Automation Manager and by third-party plug-ins like the Polyworks Inspector Plug-in.

Polyrix and Exact Metrology say users do not need to program inspection trajectory, unlike CMM and robotic scanning solutions, as PolyScan XL scanners capture data from every angle. The scanners do not require costly enclosure and safety systems, and the zero-movement setup means there is no risk of collision with operators. The companies also say these scanners offer fast, high-inspection throughput, generating higher returns on investment.

Sunnen SHO-965 Maintains MB-30 Performance With Lower VOC

Sunnen’s SHO-965 honing oil combines the high performance of the MB-30 oil while lowering VOC emissions to meet SCAQMD’s strict standards.

Sunnen Products has designed its SHO-965 honing oil with a low-odor, low-VOC formulation based on its most widely used general-purpose oil, the MB-30. The SHO-965 exceeds the strictest standards of the South Coast Air Quality Management District (SCAQMD), the California agency responsible for Orange County and the urban portions of Los Angeles, Riverside and San Bernardino counties – one of the smoggiest regions of the U.S., with a high concentration of metalworking operations.

The SHO-965 oil improves on odor while retaining the high-performance qualities of Sunnen’s industry-standard MB-30 honing oil, including maximum cutting rates and increased abrasive life when honing difficult materials like stainless steel.

“These fluids are the ‘lifeblood’ of Sunnen machines, and combined with our tools and abrasives, they help produce the best finishes we’ve seen,” says Chuck Korn, product engineer at Sunnen. “There are a number of MB-30 imitators, but they’re not as effective, and performance is critical for most high-tolerance parts.”

Sunnen says the SHO-965 is highly versatile, working on virtually any metal, and effective as a general cutting oil for screw machines, drilling, tapping and reaming. Its long service life – up to one year in the right conditions – also helps decrease cost per part.

“Our testing and the feedback we’ve received from the field indicate SHO-965 oil performs as well as MB-30 with much lower VOC content,” adds Korn. “Reduced-VOC fluids are a trend globally, so we are meeting the contemporary needs of the metalworking industry by reducing the environmental impact of our fluids without sacrificing performance.”

SHO-965 joins Sunnen's efficient SHO-500, MAN-863 and KG3X oils. The SHO-965 is available in 5-gallon (18.9-L) pails, 55-gallon (208.2-L) drums and 330-gallon (1,249-L) totes.

VELO3D Announces Sapphire Gen 2 and Sapphire XC Printers

VELO3D is releasing the Sapphire XC, a large-format printer based upon its Sapphire 3D printing architecture, starting in Q4 2021.

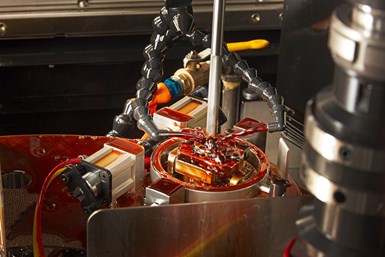

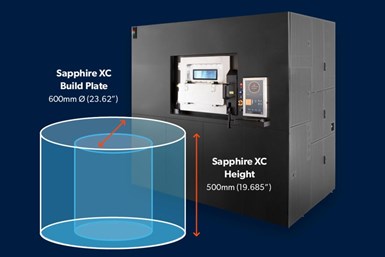

VELO3D is expanding its systems portfolio to include Sapphire XC, an “Extra Capacity” large-format printer the company says will increase production throughput fivefold and reduce cost-per-part by up to 75% when compared to the existing Sapphire system.

The company also announced plans to roll-out Sapphire Gen 2, which will be a software and hardware upgrade to the current system, starting Q2 2021. Users can expect an improvement of anywhere between 10-50% in productivity and part-cost metrics when compared to the current Sapphire system.

The Sapphire product family now includes Sapphire Gen 2, the 1-meter-tall Sapphire 1MZ and Sapphire XC – all of which use the laser powder-bed fusion (LPBF) process with patented capabilities to print without support structures. VELO3D targets its Sapphire systems to the aerospace, power generation and energy markets.

“For the first time, customers will be able to 3D-print uncompromised geometries, with the highest confidence in part quality, in a large format system,” says Benny Buller, founder and CEO of VELO3D.

Sapphire XC features a 600 mm x 550 mm build volume and eight lasers at 1,000W each, compared to the regular Sapphire’s 315 mm x 400 mm dimensions and 2 lasers at 1,000W. The printer is fully integrated with Flow pre-print software and Assure quality control software. Sapphire XC uses the same architecture as the original model, meaning users can expect similar material properties. Compatible alloys include Aluminum F357, Titanium 6AI-4V, INCONEL 718 and HASTELLOY X.

Delivery of Sapphire XC will begin in Q4 2021, with early preorders securing a special price and early manufacturing slot. VELO3D expects existing orders for Sapphire XC to consume all available manufacturing slots for Q4 ’21 and most of Q1 ’22.

Read Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)