New Metalworking Products from Modern Machine Shop, Nov. 02, 2020

The latest technology from Clemco Industries, Nagel Precision, Glebar Company, Rollomatic, and Kalamazoo Industries

Clemco Debuts User-Oriented Pulsar Plus Blast Cabinets

Clemco’s Pulsar Plus line of blast cabinets includes a variety of user-friendly optimizations the company believes will increase productivity and worker comfort.

Clemco’s Pulsar Plus line of blast cabinets provide reliable and consistent results while remaining simple to clean, low cost and highly ergonomic.

Ergonomic and user-friendly design

The Pulsar Plus cabinets feature electric, height-adjustable legs and quick-change glove ports with integrated armrests to ensure operators can work more comfortably — which the company says will reduce injuries and increase productivity. Built-in 50-watt LED lights will improve visibility while saving energy compared to fluorescent and incandescent lights.

A detached power module increases flexibility when arranging the Pulsar Plus on the shop floor. Simple access to common wear parts and programming tools allow operators to swiftly adjust the blast cabinet for different media.

Common-sense controls

Operators can easily monitor blast cabinets with Pulsar Plus, which includes a centralized operator control panel, and spend less time worrying about dirty air causing control circuit failures. The electric control circuit decreases interior complexity — Clemco says this will entirely eliminate air-related failures.

Simplified dust collection

A 1-hp exhaust motor simplifies dust removal with a timed auto-pulsing filter cartridge that will simplify the operator’s maintenance schedule and ensure maximum filter life.

Additionally, the differential pressure gauge can measure if the cartridge needs to be replaced by way of the side-access filter cartridge door. A six-gallon dust container uses interlocks for a solid connection to the dust collector.

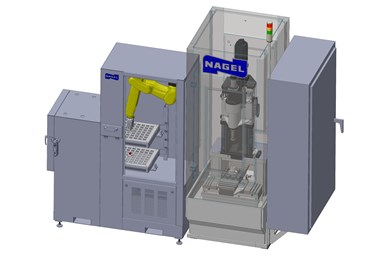

Nagel RL-2000 Robotic Loader Handles Secondary Operations

Nagel Precision’s RL-2000 robotic load system performs secondary operations to achieve lights-out manufacturing.

The RL-2000 robotic load-unload system from Nagel Precision Inc. is capable of performing secondary operations, which the company says could aid manufacturers in achieving lights-out manufacturing. Ethernet and Profinet communications systems inside the FANUC controller eliminate the need for expensive standalone controls, and the system integrates with old and new CNC- and PLC-based machines.

While traditional automatic machine tending and pallet systems are solely dedicated to loading and unloading, with separate systems for deburring, stamping, gauging and otherwise refining parts, the loader can perform these secondary operations. It is compatible with front- and side-loading applications. The operator opens the interlocked safety door, manually unloads as many as four finished trays and loads green trays. Operators can pull out the trays like drawers on heavy-duty-rail mounts, as can the robot during operation. Once each tray is complete, the robot returns the tray and pulls out the next, with sensors preventing crashes and ensuring that trays are in place. The robot can drop a finished part into a SPC chute at regular intervals for offline inspection. It can also use optional automatic gripper changers for rapid changeover.

The heavy-duty system is said to meet stringent automotive OEM specifications. The company offers customization to suit individual requirements and delivers the system turnkey.

Tridex CS1-E ECG Machine Speeds Zirconium Tube Cutoff

Tridex Technology’s CS1-E burr-free electrochemical cutoff machine is designed to increase productivity of zirconium tube cutoff, while reducing costs and fire risks.

Tridex Technology’s CS1-E burr-free electrochemical cutoff machine is designed to cut zirconium tubes at a fraction of the cost, time and risk of traditional carbide tools. By combining abrasive grinding and electrochemical erosion, electrochemical grinding (ECG) leaves tubes burr-free.

The CS1-E can cut tubes from 0.012" to 3.15" in diameter. At small diameters, the machine can even cut multiple tubes each cycle. Tests conducted by the company’s engineers showed the machine cut five 0.375" diameter tubes burr-free in 40 seconds for productivity gains as much as 90%.

The company says the ECG process produces very little heat and is safer than a lathe cutoff. For added safety and peace of mind, owners can fit the CS1-E with a fire suppression system.

Glebar Customer Care’s Tridex Companion Software for data storage is available for all of the company’s CS1 electrochemical cutoff machines and SG series ECG Surface Grinding Machines with PLC controls. The software converts setups, cuts lists and user programs into Windows files, allowing offline storage and archiving.

Rollomatic GrindSmart Offers Flexibility for Tool Grinding

Rollomatic’s GrindSmart 630XW six-axis tool grinder allows manufacturers to grind a variety of indexable inserts and round-shank tools on a single machine.

Rollomatic’s GrindSmart 630XW machine is designed to offer more flexibility in grinding indexable inserts and other stationary cutting tools than conventional, single-purpose grinders. With its six fully interpolated CNC axes, a six‐station wheel changer and wheel inclination ranging to 45 degrees, the machine supports simple adaptation for short and long runs of individual insert designs. Its design allows full interchangeability between inserts and round tools, according to the company.

The clamping systems are designed to emulate the way inserts fit into their tool holders, increasing concentricity and accuracy. The clamping design supports indexable, non‐indexable and replaceable inserts; threading and form inserts; dog‐bone and grooving inserts; drilling, milling and ballnose tip inserts; and other non‐round tools. An electronic touch probe determines the exact location of the insert blank after clamping, allowing the software to grind the tool geometry according to the virtual centerline of the insert blank and achieve a run-out of 0.0001", according to Rollomatic.

The company says the machine’s six- or 16-station wheel and nozzle changer offers flexibility for grinding a variety of inserts and other stationary cutting tools while maintaining the ability to change to round‐shank tools within minutes.

Additional features include an IC diameter range from 3.9 to 25.4 mm with automatic handling, linear motion control on CNC axes, desktop tool design software with 3D tool simulation and 3D machine animation with collision warning, chipbreaker grinding on the rake face, edge preparation grinding on the cutting edge, and a pick-and-place robot that protects inserts from damage after grinding. Optional features include a part flipper, an in-process rotary dressing and an automatic sticking device.

Kalamazoo Saws Serve A Variety of Manufacturing Needs

Kalamazoo Industries’ C370A-NC EXT cold saw, K44ERF abrasive saw, K20E cutoff saw and KS652 canted-head bandsaw address a range of manufacturing needs.

Kalamazoo Industries recently debuted four saws, each designed to serve a specific manufacturing need: the C370A-NC EXT, K44ERF, K20E and KS652.

The C370 A-NC EXT cold saw is a fully automatic, heavy-duty vertical column machine emphasizing vibration-free sawing. The 48" index feeder can produce longer workpieces without having to stop and re-set indices. The cold saw features infinitely variable blade speed control between 13 and 89 rpm for precise sawing, while the air-over-hydraulic system optimizes sawing rates.

The K44ERF enclosed abrasive saw cuts refractory materials such as high-temperature insulating materials and precast shapes. The vertical column cutoff saw features a 75-hp, 3-pin-hole motor and a 44" diameter diamond-edge blade, while the enclosure keeps dust inside the cabinet. Customers can customize the machine’s size to fit their existing conveyors and workholding equipment.

The K20E features a 15-hp, 3-pin-hole 1950-rpm motor in 220 and 440 volt variants, as well as a 1" spindle arbor. The saw comes with an air/oil power downfeed, air chain vise and coolant pump system with dual coolant hoses. The 20" enclosed metallurgical cutoff saw specializes in wet-cutting metal samples and inspecting workpieces’ internal properties after processes like heat treating or proofing a mold.

The KS652 features heavy construction and advanced design to yield vibration-free sawing and long blade life at high production rates. The semi-automatic double-column, canted-head bandsaw has a 1.5" blade and a full 26" vise opening engineered to cut structural, solid and difficult materials such as W24 beams.

Read Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)