New Systems and Software Products from Modern Machine Shop, Dec. 27, 2019

The latest technology from NCG CAM Solutions, INDEX, GF Machining Solutions, Kubotek3D, and CGTech

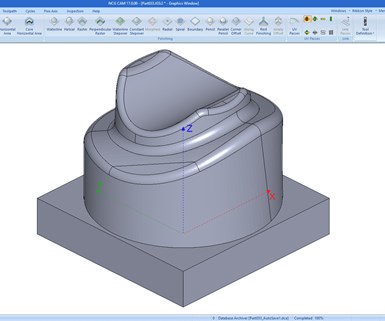

NCG CAM v17.0 Updates UI with Ribbon Design

NCG CAM v17 features an updated user interface whose ribbon design organizes the program into a series of tabs at the top of a window.

NCG CAM v17 features an updated user interface whose ribbon design organizes the program into a series of tabs at the top of a window. According to the company, the new ribbon layout will make it easier for the user to discover new features and functions.

Dynamic Material Removal has been added alongside the existing cutter animation function. It can indicate the direction of milling (climb or conventional) and identify any gouges or collisions. The feature is said to enable better visualization and verification of the material stock removal produced by the calculated tool path.

The software’s Drilling - Hole Shape Database and Compound Drilling Cycles can create a searchable database of hole shapes. Several cycles can be grouped together as compound cycles to apply them to specific hole shapes. The Compound Drilling Cycle can also be applied to holes of different directions (tool axis), so that holes with different directions but the same hole shape can be programed in one step.

The Coordinate System module has been extended to include axis rotation information. The user can create a points folder containing key reference points and define the orientation. The module then repositions the imported part(s) or tool path(s) to the selected plan.

Another new feature enables the user to project a 2D boundary onto the surface. 3D curves can now be projected from a 2D boundary. This is mainly aimed at 3+2-axis machining, since existing boundaries are drawn above the surfaces along the tool axis, the company says.

Index Traub's Data-Driven iX4.0 Software Connects and Monitors Machine Tools

Index Traub offers iX4.0, which integrates Index and Traub machines as digital twins.

Index Traub offers iX4.0, which integrates Index and Traub machines as digital twins. New machines are provided with the iX4.0 Go starter package, which provides trial access to iX4.0 applications. The open platform is said to ease connecting older Index and third-party machine tools.

The platform’s AlarmMessenger informs the operator of unscheduled downtime. Status Monitor provides monitoring transparency for processing MDA and ODA data. Spindle Check collects information on speed, spindle load, temperature curves and other data, evaluates it, and displays it in graphical form. Axis Check performs the same tasks for the linear axes of the machine.

The platform is intended for use in conjunction with the company’s iXshop and iXservices portals, which are designed to provide digital support for the entire process chain. The former application is a procurement platform enabling users to purchase toolholders, accessories, clamping devices, spare parts and raw materials. The latter is a platform for managing fault, repair, maintenance and care orders, including teleservice.

GF Machining Solutions' Spark Track Monitors, Adjusts EDM Wire for Irregular Shapes

GF Machining Solutions’ Spark Track technology for wire-cutting EDMs prevents wire breakage that occurs when cutting irregularly shaped workpiece features.

GF Machining Solutions’ Spark Track technology for wire-cutting EDMs, powered by the company’s Intelligent Spark Protection System (ISPS) module, prevents wire breakage that occurs when cutting irregularly shaped workpiece features. With Spark Track technology and the ISPS module, wire EDM users gain secure and uninterrupted EDM processing, improved machining efficiency and ease of use for operators, the company says.

Spark Track constantly monitors the spark distribution along the EDM wire. Based on the spark data gathered, the ISPS analyzes and automatically recognizes shape changes, adapting machining parameters accordingly to prevent wire breakage during roughing. As a result, irregular shapes such as cavities, varying heights, taper surfaces and sharp corners can be more easily roughed without the need for operator intervention to set up machining conditions in advance, the company says. The resulting reliability allows for full automation.

Angled part surfaces represent an example of where Spark Track and the ISPS module bring high efficiency to the wire EDM process, according to the company. Such tapered surfaces can create non-homogenous flushing conditions at a wire EDM machine’s upper nozzle, disrupting the machining process. The ISPS module is said to eliminate the need for the machine operator to adjust the machining process to accommodate such difficult machining conditions since it analyzes the spark distribution data, automatically recognizes the shape change and adjusts the process to increase machining efficiency.

K-Display and K-Compare 2.0 from Kubotek3D Enable CAD File Comparison, Analysis

Kubotek3D’s 2.0 release of its K Compare CAD file discrepancy reporting and K-Display MCAD visualization software products includes K-Compare Revision.

Kubotek3D’s 2.0 release of its K Compare CAD file discrepancy reporting and K-Display MCAD visualization software products includes K-Compare Revision for creating reports detailing the differences between two versions of the same CAD model. The other three products in these Kubotek product lines have been enhanced since their last major release with eight updated CAD file translators and several new measurement and/or visualization functions.

K-Compare Revision is built on the Kubotek Kosmos 3D framework. It automates portions of the process for engineers documenting a change to a part, enabling users to identify all changes to the model and data; communicate detailed understanding of changes to all stakeholders; handle design files from any major source; and quickly create complete reports.

A simple cutting plane function has been added to K-Display products which allows users to visualize the interior sections of complex parts. Additionally, the wireframe display mode has been enhanced to include silhouette edges, which improves visualization of part geometry.

Two measurement functions have been added to K-Display products. The first new function analyzes 3D models of plastic parts to find areas which are difficult or impossible to create with a simple mold strategy. The other new measurement function supports quick overall measurements of the envelope of selected 3D models by wrapping them with temporary “bounding box” solids.

The ability to compare folders of part files and assembly files which include references to part files has been significantly enhanced in version 2.0. These new features allow users comparing a large batch of files to line up corresponding pairs of files into horizontal rows to simplify visualization.

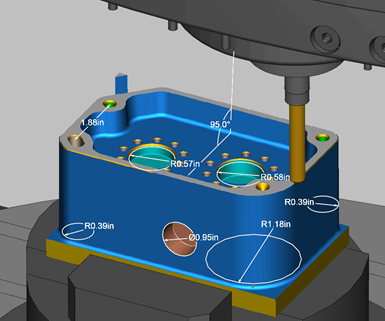

Vericut 9.0 Features New Graphics Engine for Easier CAM Verification

Version 9.0 of Vericut from CGTech is described as “smarter” than previous versions, offering more robust connections to tooling databases and CAM systems.

Version 9.0 of Vericut from CGTech is described as “smarter” than previous versions, offering more robust connections to tooling databases and CAM systems. Vericut machine simulation, verification and optimization software simulates all types of CNC machining, additive and hybrid manufacturing processes.

Commenting on the new version’s improvements, Product Manager Gene Granata says, “Most users will also experience gains in performance, especially when simulating additive or hybrid AM operations. Enhancements to Vericut’s free Reviewer app lets programmers share with others (like machinists or quality assurance personnel) how parts are manufactured.”

Vericut 9.0 features several enhancements designed to increase power and improve efficiency, including a new graphics engine. The software provides sharper, clearer and more realistic views of machines and the machining process, making it easier to spot problems and imperfections in machined parts. Appearance settings for components and models can be used to add realism to objects in simulations.

Verification has been streamlined in version 9.0. Any of Vericut’s major functions, such as AUTO-DIFF, Section, and X-Caliper, can be used in any view, which also increases productivity.

Using Force “Analyze”, users can spot potentially dangerous machining conditions or identify underutilized tools without any prior configuration. Force Charts has a new “Fill Comparison” option to help visualize the changes made by Force optimization to feed rates and chip loads.

X-Caliper now has several new measurements as well as features that provide greater control over how measurements (dimensions) are shown. Images with dimensions can be printed, saved to an image file or utilized in Setup Plans. Setup Plan capability is designed to ease the creation of images from the simulation with dimensions or notes that help others understand the manufacturing process.

Read Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)