New Systems and Software Products from Modern Machine Shop, Mar. 18, 2021

The latest technology from Methods Machine Tools, VisionX, GF Machining Solutions, Renishaw, and The L.S. Starrett Co.

Datanomix Debuts Fusion GEMBA Functionality

Datanomix has launched its Fusion GEMBA product, which automatically gathers data from company ERP systems to produce a real-time GEMBA board.

Datanomix has launched its Fusion GEMBA product. This new offering takes the GEMBA approach to streamline continuous improvement operations and planning.

The product’s headlining feature is a digital GEMBA board — a real-time indicator of key factory metrics around safety, quality, delivery, cost and inventory that offers quick visual drill-downs into any customer, project or part. The software operates automatically, only requiring a connection to the ERP system.

Fusion GEMBA continues to build on Datanomix’s production intelligence mission by automatically pulling together critical metrics that describe important facets of factory operations, making people aware of whether performance is increasing or not, and why. Where Fusion Monitoring quantifies individual job performance using real-time data from manufacturing equipment, Fusion GEMBA leverages existing ERP data to derive intelligence at the factory level.

“We designed our GEMBA software from the user up, to be automated, real-time, simple to follow and serve as the pulse of the entire factory at a glance,” says Greg McHale, Datanomix co-founder and CTO. “Fusion GEMBA automatically retrieves vital operations information, sorts it and updates it constantly in order to deliver a dynamic view of the entire operation as it is happening.”

“Our customers asked us to automate their GEMBA workflow to streamline continuous improvement efforts while improving overall communications across the plant,” says John Joeseph, Datanomix CEO and co-founder. “They needed a heads-up display for their factories and we provided it to them in a way that is seamless, easy to follow and requires zero input from them. We let their ERP systems chug along while we amplify the critical factory information that people can act on right now.”

Fusion GEMBA is available with Fusion Monitoring or as a standalone product. Datanomix recommends running both software products on smart TVs.

Methods Machine Tools Releases VisionGauge OnLine Updates

Methods Machine Tools has released software enhancements for VisionGauge OnLine, especially benefitting VisionX’s Digital Optical Comparator 700 series.

Methods Machine Tools Inc. recently announced new software enhancements to VisionX’s VisionGauge OnLine machine vision software for automated inspection, verification and data collection.

Methods says one of the main upgrades improves the speed and usability of the five-axis VisionGauge Digital Optical Comparator 700 series for measurement and inspection. The upgrade gives users two options to supply the measurement system with hole coordinate data directly from a electric discharge machining (EDM) drill, laser or machine tool. Once transferred from the machine to the Digital Optical Comparator 700 Series, users can display the data using a computer-aided manufacturing (CAM) software package.

GF Machining Offers OPC UA 1.0 Common Communication Solution

GF Machining now offers OPC UA version 1.0 as a cross-platform communication and connectivity solution, pushing closer to the Industry 4.0 ideal.

As part of its push towards Industry 4.0, GF Machining Solutions now offers North American manufacturers the Open Platform Communications (OPC) Unified Architecture (UA) interface version 1.0 as a connectivity solution. The OPC Foundation’s cross-platform interface paradigm provides a common communication language across GF Machining Solutions’ products, technologies and services, while simplifying connection to existing enterprise resource planning (ERP) systems. This streamlines the collection and analysis of personalized key performance indicator (KPI) measurements across operational levels.

GF’s digital solutions like the rConnect Dashboard work in tandem with the OPC UA interface to help manufacturers reduce machine downtime, monitor performance across entire facilities, fully automate operations and ensure manufacturing process compliance. Version 1.0 of the OPC UA works with rConnect Dashboard to collect data and make it accessible on the shop floor or through mobile devices.

GF Machining Solutions leverages OPC UA to gather information from five major data groups: machine identity, state/status information, process information, utilization and logs. Machine identity includes meta information for identification; machine state data lists basic information like the machine’s current assigned job and activity status; process information provides remote access to messages, warnings and errors from the machine; utilization data traces KPIs like actual production time (APT), actual unit setup time (AUST), actual unit delay time (ADET), actual unit busy time (AUBT) and actual unit processing time (AUPT); and logs track the start and end times of jobs, multiple executions of a job, lead time, start/end time and numerical control (NC) program names.

Because the interface involves connectivity to office networks and the internet, OPC UA features built-in security based on standards such as Secure Sockets Layer (SSL), Transport Layer Security (TLS) and Encrypted Communication Data based on Advanced Encryption Standards (AES). The International Electrotechnical Commission (IEC) recognizes OPC UA as the IEC 62541 standard.

Avatara Launches Unified, AI-Driven Communications Suite

Avatara has launched its next-generation CompleteCloud unified communications software. This release includes a self-healing artificial intelligence, Ava.

Avatara has launched version 2.0 of its CompleteCloud Unified Communications as a Service (UCaaS) platform. This platform employs an upgraded version of Avatara Connect and Avatara’s self-healing artificial intelligence (AI), Ava. Avatara says Ava increases productivity through automated issue resolution and informatics that drive business decisions.

“It’s time for executives to stop worrying about IT and instead leverage it as a competitive advantage,” says Ben Scully, president of Avatara. “CompleteCloud 2.0 is a smart platform that was built for security- and productivity-conscious businesses. It’s a single-source solution that’s fully supported with predictable economics.”

Avatara says its unified software answers mobility, compliance and collaboration issues in business technology exposed by the COVID-19 pandemic of 2020.

“Since Avatara was founded in 2005, we’ve been working toward a unified, AI-backed platform that would allow us to collect data in a comprehensive manner that’s never been done before,” says Rob McCormick, founder and CEO of Avatara. “CompleteCloud 2.0 will change the way business owners view, engage with and control their company’s output and cybersecurity.”

The company says CompleteCloud’s big-data-fueled business analytics help business owners make decisions that affect employee productivity and cybersecurity. Additionally, as Ava is a self-learning AI, it will continue to develop and provide more benefits for users — already increasing the level of security and uptime of the engineered core environment since launch.

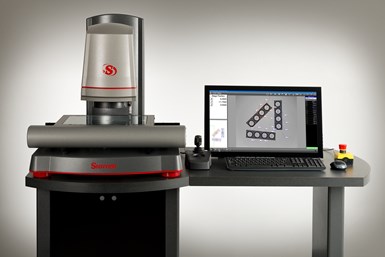

Starrett AVR-FOV 0.14X Provides Widest Yet AVR Field-of-View

Starrett’s AVR-FOV 0.14X features a 0.14 magnification lens with the widest-yet AVR field-of-view, and delivers measurements accurate to the micron level.

The L.S. Starrett Company has launched the AVR-FOV 0.14X, a variation of its AVR300 Multi-Sensor Vision System. This variation features a 0.14 magnification lens with Starrett’s largest field-of-view to date on the AVR Series, at 2.36" x 1.90" (60 mm x 48 mm). With “superimage” technology, which stitches together multiple images to form one larger image, and touch probe technology, Starrett says the AVR-FOV 0.14X can accurately inspect a wide range of features on large and complex parts, as well as multiple small parts.

The AVR-FOV 0.14X’s automated part programs deliver accurate results to the micron level in a matter of seconds with “Go/No-Go” tolerance zones, and provide data in one easy-to-interpret report. Starrett says these features help metrology users in manufacturing facilities or QC labs produce accurate, fast and repeatable results.

"Building on the success of the AVR300 multi-sensor system, customers can now measure and inspect a wider range of parts, including those that are complex with intricate features," says Mark Arenal, general manager of Starrett’s Metrology Division. "The interface on the AVR-FOV 0.14X is user-friendly and intuitive so all users, including operators on the shop floor, can complete the inspection process."

The AVR-FOV 0.14X lens comes equipped with MetLogix’s M3 software package, a mouse and a touchscreen monitor to simplify user interaction. Programmable light outputs can integrate into the program as defined steps, such as activating when the automatic part recognition program initiates. An optional Renishaw touch probe quickly acquires discreet points along a part’s profile, as well as Z-axis measurements.

Starrett says the AVR-FOV 0.14X has an XYZ travel of 12" x 8" x 8" (~300 mm x 200 mm x 200 mm).

Read Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)