New Tooling Products from Modern Machine Shop, Apr. 30, 2021

The latest technology from , and Tungaloy America

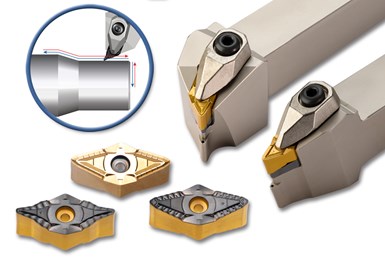

Ingersoll Introduces Superturnz Inserts

Superturnz, a multi-directional turning system that uses the front and back cutting edge of a four-corner insert, is now available from Ingersoll.

Ingersoll now offers Superturnz, a multi-directional turning system that uses the front and back cutting edge of a four-corner insert. According to the company, it is an alternative to conventional turning, where 80- and 35-degree corner inserts are fed in the same direction.

Superturnz uses all four directions available on a conventional two-axis lathe (+Z, -Z, +X and -X) to maximize material removal. The double-sided positive SuperTurnZ inserts have the same axial and radial rake angle and capability as standard ISO positive inserts, allowing for low cutting forces, but with additional cutting edges and higher feed rate capabilities, according to Ingersoll.

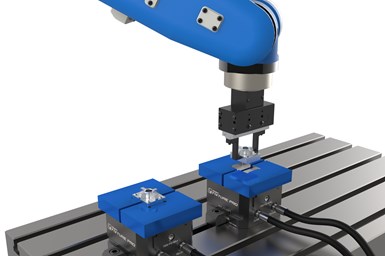

Jergens Releases Double-Acting Hydraulic Vise

Jergens' 130-mm hydraulic vise offers high holding forces, quick clamping and repeatability, according to the company.

Jergens’ 130-mm double-acting hydraulic vise, shown here in an automated application, provides high holding forces, quick clamping and repeatability for improved speed and higher part tolerance, according to the company.

Jergens Inc. has released its 130-mm double-acting hydraulic vise. According to the company, features include high holding forces, quick clamping and repeatability for improved speed and part tolerance. It comes with multiple mounting patterns, different jaw options and plumbing and maintenance ports.

Jergens’ 130-mm hydraulic vise offers jaws that may be positioned outside of the dimension of the workpiece to minimize travel when clamping. This, in combination with the speed of hydraulic workholding, reduces clamping and unclamping operations to about one second, Jergens states. According to the company, the vise may increase measurable machine uptime and productivity. It is well-suited for high mix, low volume manufacturers.

The vise is made up of a steel body and internal hardened (low-friction process) components, which reportedly increases durability. It has low operating pressure requirements so it can perform directly off of machine hydraulics. It comes equipped with Fixture Pro QLS and industry-standard 96-mm Quick-Loc mounting patterns. The 130-mm vise is suited for multiple CNC machining applications, including vertical, horizontal, rotary, five-axis and robotic setups.

Additional holding options include quick-change soft jaw sets, available in high-strength aluminum (blue anodized finish) or low-carbon steel (black oxide finish). Case-hardened jaw inserts are also available, which are well suited for first-pass operations in raw materials.

Jergens also offers hydraulic pump kits for powering the hydraulic vise, which include the compact pump — mounted horizontally or vertically — and a manual or solenoid zero-leak valve to control the clamping action. Clamping force can be adjusted with the filter/regulator, which is also included. These kits are designed for powering single-vise setups, however, multiple vise applications are also possible.

Eltool Expands Live Lathe Tool Offerings

Eltool offerings have expanded to include live lathe tools with 5:1 and 1:5 gear boxes for high-torque and high-speed machining.

Eltool has added live lathe tools with 5:1 and 1:5 gear boxes for high-torque and high-speed machining applications to its offerings. According to the company, speeders are available to improve surface finish and reduce cycle time when machining small holes and soft materials without the use of acceleration ramps. Reducers optimize the lower-speed, higher-torque requirements of large holes and tough materials without sacrificing horsepower, according to Eltool.

In-line holders are designed to use ER-style collets. They are available on extensions to machine between chuck jaws. Angle head versions are designed to fit popular lathe models and machine in bores down to 5/8" diameter. Secondary ID machining operations, such as oil grooving and keyway cutting, can be integrated into turning operations, according to Eltool. The heads and drivers are modular, and available in both face and OD mount configurations.

Greenleaf Introduces Xsytin-360 End Mills

Greenleaf's Xsytin-360 solid ceramic end mills offer high material removal rates and increased productivity, according to the company.

Greenleaf Corporation has introduced a line of solid ceramic end mills: Xsytin-360. The end mills are composed of Xsytin-1, which allows users to apply chip loads similar to solid carbide end mills with higher speeds common to ceramic machining, according to the company.

Greenleaf’s Xsytin-1 material was designed to provide high wear resistance and thermal shock resistance. According to the company, Xsytin-360 end mills have shown high material removal rates and resulted in increased productivity on a range of materials. These end mills are suitable for machining a variety of materials, including high-temperature alloys, 3D-printed sintered high-temperature alloys, hardened steels, ductile cast irons and compacted graphite iron (CGI). Greenleaf states that, in hardened steels, Xsytin-360 end mills have tool life equal to high-performance carbide end mills when run at high-end speeds (11,460 RPM), while also removing over 73 cubic inches of material.

According to Greenleaf, features include:

- A flute design that is reported to minimize cutting forces, reducing vibrations and optimizing tool life

- High strength and wear resistance at extreme feed rates

- Four-flute design for maximum material removal in slotting, pocketing and profiling applications

- Regrind capabilities

- A broad application range

- Increased feed rate capability and broad speed range

- Increased material removal rates (MRR) of 100% over carbide

The mills are suitable for machining materials in the aerospace, automotive, die and mold and power generation industries.

TungBore-Mini Boring Toolholders Improve Chip Evacuation

Tungaloy has released boring toolholders for its TungBore-Mini line. The company says these toolholders maximize chip evacuation for small-diameter boring contexts.

Tungaloy has expanded the multifunctional turning and boring capabilities of its TungBore-Mini line with boring toolholders that accommodate its unique XOMU inserts.

The company says its toolholders’ designs ensure secure ID machining processes. The design provides significant clearance between the tool and the hole surface to improve the evacuation of chips generated during boring or ID turning of small diameter bores.

Tungaloy’s angled screw fixation method employs an engaged screw that not only presses the insert against its primary bottom support, but also pulls the insert into the pocket wall. This design enables the use of a longer screw, providing strong insert retention and process security.

TungBore-Mini is a multifunctional drilling and turning tool line that integrates the capabilities of drilling, OD and ID turning tools. The geometry of its unique XOMU insert incorporates a large inclination angle on the cutting edge, producing lighter cutting than the standard ISO positive turning inserts typically used for ID turning or boring operations. TungBore-Mini’s insert and pocket also have a dovetail interlocking design that the company says provides better insert clamping and stability than standard screw-down insert clamping, enhancing process security during various applications.

Tungaloy has released eight variations of its boring toolholders for TungBore-Mini. These toolholders are available for minimum bore diameters of either 10 mm or 14 mm, with either a steel or a carbide shank.

Read Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.JPG;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)