NUM Flexium Office Enables Offline ISO Part Program Simulation

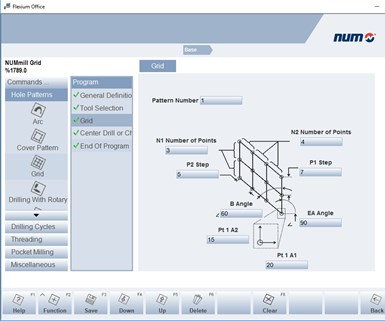

NUM’s Flexium Office software framework enables users of CNC machine tools to generate and test ISO part programs offline with NUM human-machine interfaces (HMIs).

NUM’s Flexium Office software framework enables users of CNC machine tools to generate and test ISO part programs offline with NUM human-machine interfaces (HMIs). The corresponding ISO part program can be created offline and then tested using NUM’s Flexium 3D simulation software before being transferred to the target machine.

NUM’s application-specific HMIs form part of the company’s Flexium CAM software suite. The HMIs are said to cover every type of CNC machining operation, including hobbing, shaping, milling, threaded wheel grinding and cylindrical grinding.

After selecting the most appropriate technology HMI for the task, the Flexium Office user can carry out basic data definition tasks for a project, using the intuitive tools and workflow commands provided by Flexium Office. Multiple projects can be started and saved at any time. As soon as the user is satisfied with the process and workflow of a project, it can be used to generate the corresponding CNC part program automatically.

The CNC program can either be transferred directly to a nominated machine in the production plant, usually via a TCP/IP network, or input to NUM’s Flexium 3D simulation software for thorough evaluation before being issued for production purposes. The key advantage of simulation is that it enables users to optimize any ISO-code part program offline, further helping to maximize productivity by leaving the CNC machine tool free for manufacturing purposes, the company says.

NUM’s simulation software provides full visualization of the tool center point path and workpiece material removal, backed by automatic checking for collisions between machine components, the tool and the workpiece. The software creates a color image showing the workpiece as a 3D volume that can be rotated and viewed from any perspective.

Related Content

-

CAD/CAM System Requirements: An Overview

CAD/CAM programs are among the most demanding kinds of computer software. Smooth operation requires careful consideration of computer specifications.

-

Integrated CAD/CAM Promotes Process Efficiency, Traceability

High-requirement markets are not only searching for good parts — they're searching for proof of good parts. CAD/CAM software can help.

-

Grinding Simulation Enables Growth in Custom Tooling

Simulation software both streamlines Gorilla Mill's grinding machine setups and speeds up the company's tooling design and verification processes.

.png;maxWidth=300;quality=90)