NUMmonitor Software Enables Monitoring of Transfer and Multi-Process Machines

NUM’s NUMmonitor software is said to enable users of multi-process CNC machine tools such as transfer machines to implement process monitoring without incurring additional hardware costs.

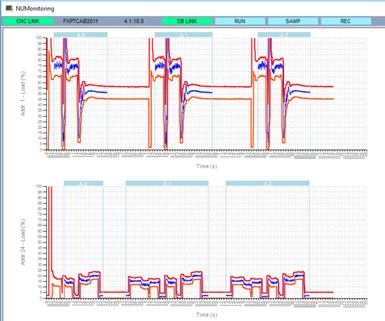

NUM’s NUMmonitor software is said to enable users of multi-process CNC machine tools such as transfer machines to implement process monitoring without incurring additional hardware costs. Through real-time monitoring of the power/current values of the electric motors on a transfer machine throughout its milling, turning or grinding processes, NUMmonitor minimizes downtime and maintains production quality by guarding against faults, the company says.

The software initially operates in “learn” mode to acquire the varying loads and drive currents of motors when the CNC machine tool is running at optimal performance levels and with a sharp new tool. Eight motors can be monitored simultaneously throughout the machine’s operating cycle, and the software accommodates up to 11 different error detection criteria per motor. In the case of multi-NCK systems, an additional eight motors can be monitored for each additional NCK.

Cycle-time related operating parameters determined from this process form “known good” event references which can then be used for comparison purposes against data sampled during subsequent production runs. User-programmed amplitude, duration and integral thresholds determine whether an event constitutes an “alert,” “alarm” or “shutdown” condition.

The new NUMmonitor software option can be installed and used on any Flexium+ CNC system running NUM’s Flexium software version 4.1.10.10 or higher. The Flexium+ includes a PC which can handle data from the servodrives’ measurement points, a programmable logic controller (PLC) with direct access to machine parameters and an NCK oscilloscope capable of reading values in real time. All system communications are handled by FXServer, using fast real-time Ethernet (RTE) networking.

Related Content

-

Shop Moves to Aerospace Machining With Help From ERP

Coastal Machine is an oil and gas shop that pivoted to aerospace manufacturing with the help of an ERP system that made the certification process simple.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

.png;maxWidth=300;quality=90)