Sandvik Coromant's CoroBore 825 Uses Special Damper Technology

Sandvik Coromant’s updated CoroBore 825 fine boring tool applies the company’s Silent Tools technology, with dampers dimensioned specifically to suit every adapter size in the assortment.

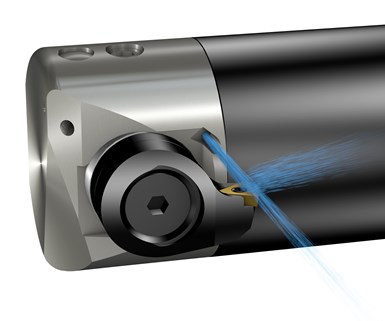

Sandvik Coromant’s updated CoroBore 825 fine-boring tool applies the company’s Silent Tools technology, with dampers dimensioned specifically to suit every adapter size in the assortment. This is said to elevate process security where vibration issues are frequently encountered, such as when machining with long overhangs, and also to improve productivity since cutting data can be increased. Among the principal updates in the latest-generation tool is the change of boring head material from steel to aluminum. In addition, the head has been shortened so that the damper comes closer to the cutting edge, which is beneficial for process stability.

“Internal channels are utilized to deliver coolant directly to the cutting edge, which is another factor that contributes to improved surface finish, higher penetration rates and greater process security,” says Jenny Nilsson, global product manager. “The new generation of tools will provide optimum performance and stability with one standard adaptive item on the machine tool side, to bridge the tool into a steep taper, HSK or Coromant Capto spindle. Further extensions will reduce stability and performance.”

The CoroTurn insert carriers for the new tools have entering angles of 92 to 95 degrees. This design increases stability due to reduced tool assembly deflection, making it possible to approach the bottom of a blind hole without engaging a greater part of the cutting edge, the company says.

CoroBore 825 is designed for all fine-boring applications, covering diameters ranging from 19 to 167 mm (0.748" to 6.575"), while a new assortment of cartridges can be used for back-boring applications. During back boring, the same internal coolant flow to the cutting edge is offered as in conventional boring.

Related Content

-

Walter Launches New Solid Carbide Drill

The DC118 Supreme solid carbide drill provides high rigidity against deflection, superior centering accuracy and four margins with corner chamfers.

-

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

-

How Lowering Torque Improves Tapping Tool Life

Escaping the tap breakage trap requires a long look at torque and the many factors that influence it.

.png;maxWidth=300;quality=90)