Software Enables Cloud Collaboration Tools for Additive Manufacturing

The Solid Edge ST10 version eliminates the need to transfer data between applications and includes cloud-based collaboration tools.

Solid Edge ST10 software from Siemens PLM Software is designed to bring ease to optimizing parts for additive manufacturing (AM) and obtaining quotes, material selections and delivery schedules from AM service providers. Combined with Siemens’ convergent modeling technology, it enables designers to improve product design efficiency and streamline the ability to work with imported geometry.

The software incorporates cloud-based collaboration tools to enable collaboration between users, suppliers and customers. Users can upload and manage files in cloud-based folders. Multi-platform, browser-based viewing, and improved publishing tools enable the creation of interactive technical documents. Component classification and offline working are supported using embedded Teamcenter integration.

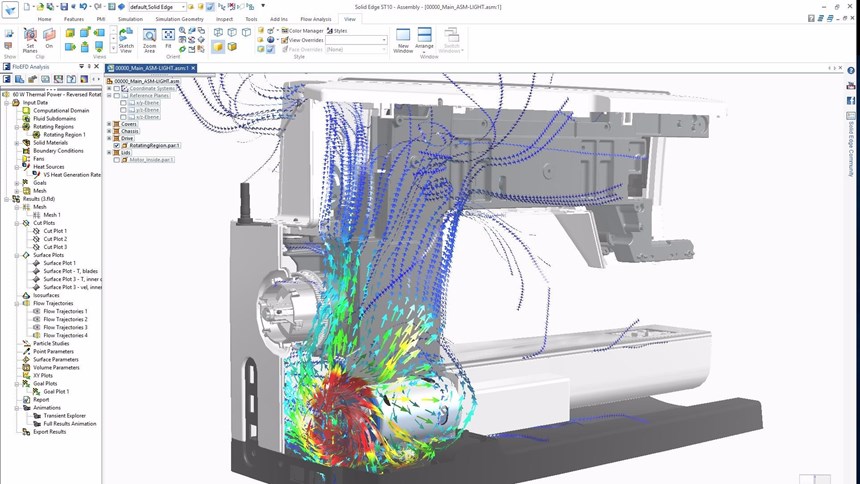

New simulation capabilities, such as fully-integrated fluid-flow analysis, eliminate the need to transfer data between applications, giving designers the ability to achieve accurate, fast fluid flow and heat-transfer analysis.

Integrated CAM capability enables efficient programming of CNC machine tools, and new tools enable users to print parts in-house or access a network of AM services.

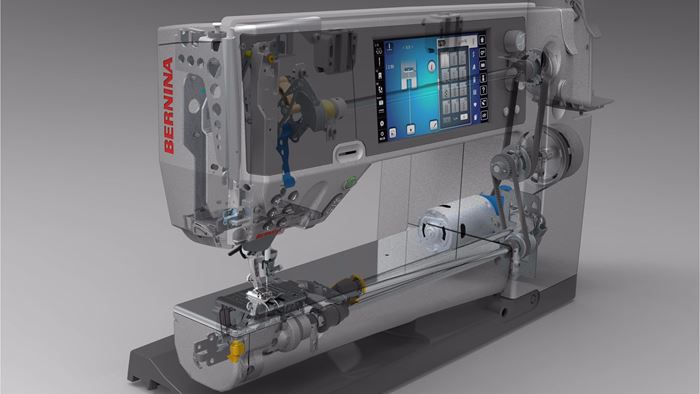

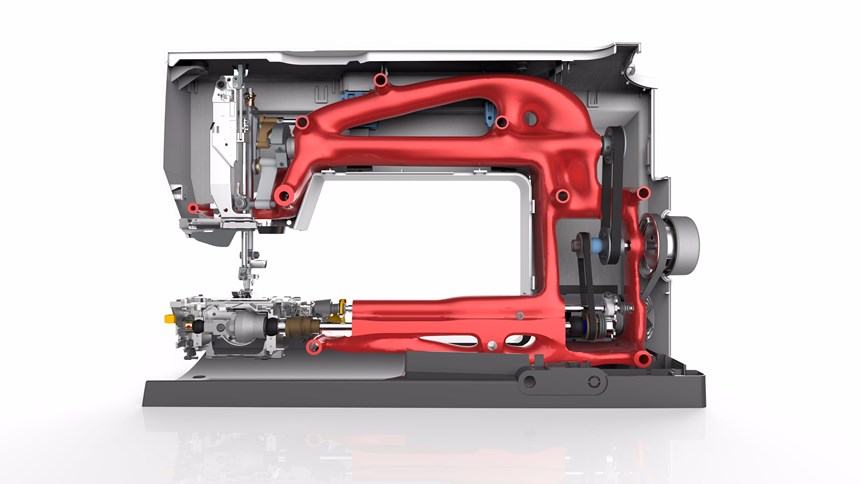

Solid Edge ST10 also includes enriched publication features to quickly create detailed illustrations of designs. Publishing interactive digital documents helps communicate the correct manufacturing process and maintenance procedures.

Related Content

-

The Cool Parts Showcase Seeks Innovative 3D Printed Parts

Do you solve problems with 3D printing? Enter your 3D printed parts in this contest from The Cool Parts Show.

-

4 Ways 3D Printing Is Changing Medical Implants

Additive manufacturing provides new ways of making medical implants, but its impact is greater than this. How 3D printing is changing medical manufacturing and improving patient outcomes.

-

In Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.