Spreadsheets Enable Calculations Similar to CAM Software

Spreadsheet software can behave like a CAM system.

Spreadsheet can be used like CAM software.

You probably use spreadsheets every day. They are great for a multitude of applications—everything from creating grocery lists to organizing your company’s production information. If you program CNCs, you probably use a computer-aided manufacturing (CAM) system. But did you know that you can get a spreadsheet to behave like a uniquely customizable CAM system?

Obvious spreadsheet features, such as entering data into cells or displaying calculated results in others, along with the ability to format results as strings of data, enable the creation of G-code commands that consider and manipulate current values in input-data fields.

Running through an example can illustrate how a spreadsheet can function like CAM software. Consider this: spreadsheet cell J7 contains the diameter of a milling cutter that will machine a contour. Other cells contain input data about the contour, but let’s keep it simple for now. The X-axis-approach position for this milling cutter will be to the left (X negative side) of the program origin by the cutter radius plus a 0.1-inch-approach distance. For a 1.0-inch cutter, the required G-code command will be:

G00 X-0.6

Here is a Microsoft Excel spreadsheet formula that will generate the required command:

=“G00 X-” & FIXED(J7/2+0.1,4)

The equal sign begins a formula. Quotations surround a text string. The ampersand specifies information that will be added to the text/data. The “fixed” function enables the specification of decimal point values. Note the “4” after the comma specifies that the calculated value will be displayed to four places.

Looking at the calculation within the parentheses, the current value of cell J7 is 1.0. When 1.0 is divided by two (0.5) and then added to a value of 0.1 (the clearance amount), the result is 0.6. The result of this formula (with cell J7 currently set to 1.0) is:

G00 X-0.6000

This should seem familiar if you have experience with custom macro. Indeed, just about anything you can do with a custom macro program can be done with spreadsheet software.

One advantage of using a spreadsheet instead of a custom-macro program is that the control will not have to perform calculations or make decisions during the program’s execution. Another benefit is that the CNC machine tool need not be equipped with custom macro or any version of parametric programming.

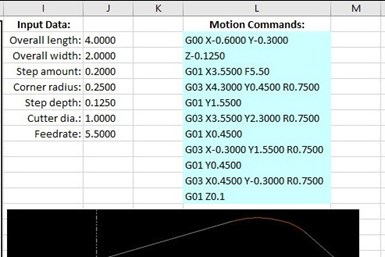

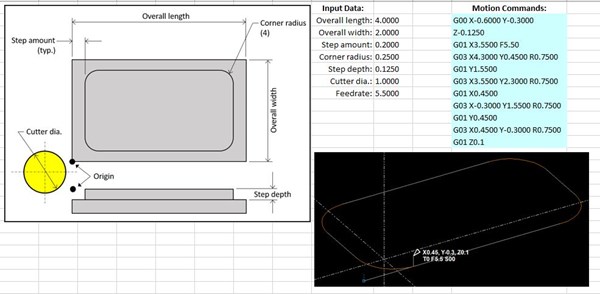

The illustration below shows a more elaborate example to demonstrate what is possible.

The drawing shows the contour to be milled, along with the variable names for input data. The list of input data is to the right, and to the right of that are the resulting G-code motion commands. The created tool path, which is not interactive, is shown as well.

As you change an input-data value, the related motion commands immediately change. Once all input data are appropriately set, you can copy the motion commands from the spreadsheet and paste them into your CNC program.

You can download the spreadsheet to see the formula for each motion command, but here is one of them. It is for the first G03 circular-motion command:

="G03 X" & FIXED(J2-J4+J7/2,4) & " Y" & FIXED(J4+J5,4) & " R" & FIXED(J5+J7/2,4)

This renders (for the current input data settings):

G03 X4.300 Y0.4500 R0.7500

Again, each ampersand will add to previous data. And as with a custom-macro program, each CNC word will be the result of a calculation that involves input data. The X-word begins with the overall length (4.0), subtracts the step amount (0.2) and then adds the cutter radius (0.5). With the “fixed” function specifying four decimal places, the result is X4.300. Similar techniques are used for other CNC words in this formula as well as for other CNC words in the other formulae.

Related Content

TTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

Read MoreBuilding A Powerful Bridge from the CAM Programmer to the Shop Floor Operator

SolidCAM for Operators provides a powerful bridge from CAM programming to the shop floor to best streamline the machine shop process with its CAM part simulation. It provides a clear picture to the operator for setup and prove-out, enables minor G-Code changes and avoids crashes, broken tools and scrapped parts.

Read MoreWhen to Use Custom Macros With a CAM System

Custom macros can offer benefits even when using a CAM system to prepare programs – but must be implemented with the right considerations.

Read MoreIntegrated CAD/CAM Promotes Process Efficiency, Traceability

High-requirement markets are not only searching for good parts — they're searching for proof of good parts. CAD/CAM software can help.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)