SurfCAM, NCSIMUL Integration Improves Efficiency

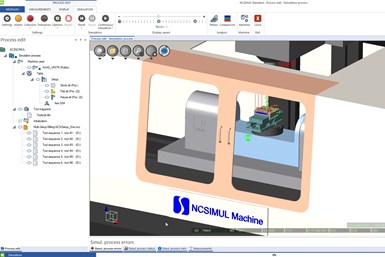

SurfCAM 2021 includes integration with NCSIMUL manufacturing simulation software to connect the virtual and real for greater flexibility and productivity.

The new version of SurfCAM Traditional CAM software offers a direct connection to the NCSIMUL machining simulation solution by Hexagon Manufacturing Intelligence, providing SurfCAM programmers with greater control over the manufacturing process and delivering a more accurate and detailed picture of each machining operation from start to finish.

SurfCAM Traditional is designed to provide manufacturers with robust, flexible, and easy-to-use programming capabilities for two- to five-axis machining, as well as turning and wire EDM programming functions. Operators can use NCSIMUL machining simulation software with a wide range of CAM systems to verify and optimize tool paths, quickly switch NC programs between machine tools, and simulate machining operations.

By using a direct link to NCSIMUL from within the SurfCAM Traditional 2021 interface, users will have access to true G-code toolpath verification, editing and simulation functions to ensure their NC programs are collision-free and reflect the full CNC machining environment. This new connection between the two systems also enables users to compare cut stock with original design geometry.

The ability to view the state of the stock model throughout the machining process, including during multiple operation parts or multiple part setup, provides machinists with the flexibility to adjust operations and prevent errors.

SurfCAM Traditional users can access NCSIMUL via the system’s operations manager, which lists set-ups for operations in scheduled order, as well as relevant machining data for each operation. From there, users can view the part within the NCSIMUL interface’s various modes, including wireframe, facet, shading and shape modes. Users can also view and edit tooling, tooling sequences and toolpaths within the same interface.

The direct link to NCSIMUL also enables users to digitally add or subtract part stock and adjust fixturing, clamps, and cutting tool libraries. Access to detailed virtual set-ups removes guesswork by providing accurate digital twins of complete machining environments that users can recreate in the real world.

Related Content

-

How Integrated CAD/CAM Transforms Inventions Into Products

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.

-

Integrated CAD/CAM Promotes Process Efficiency, Traceability

High-requirement markets are not only searching for good parts — they're searching for proof of good parts. CAD/CAM software can help.

-

Improve Machining Efficiency Through Digital Twin Simulation

Full simulation of a machining cycle using digital twins can not only identify crashes before they happen, but provide insights that enable the user to reduce cycle times.

.png;maxWidth=300;quality=90)