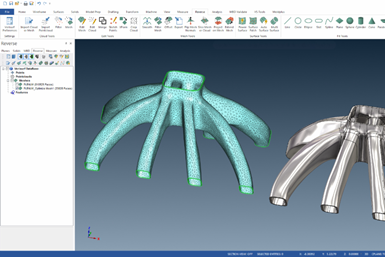

Verisurf 2020 Improves Reverse Engineering Workflows

With Verisurf 2020, users can manage CMMs, collect data from 3D scans, perform 3D CAD and Class-A surface modeling, and verify finished parts, according to the company.

Verisurf Software, Inc. has released the 2020 edition of its measurement software for automated quality inspection and reporting, 3D scanning and reverse engineering, tool building, and assembly guidance.

With Verisurf 2020, users can manage CMMs, collect data from 3D scans, perform 3D CAD and Class-A surface modeling, and verify finished parts, according to the company.

Verisurf is dedicated to model-based definition, and its designers built the code base on a CAD/CAM platform. This is said to enable greater compatibility, workflow integration and more complete end-to-end solutions.

Enhancements in the 2020 release include an array of reverse-engineering tools with new Quick Surface modeling option, expanded device support to keep up with emerging measurement and data capture technologies, additional productivity features and new features designed to support efficient measurement workflows.

Related Content

-

How to Grow the Business with Real-Time Job Status Data

ERP systems that focus on making data more accessible can improve communication within a shop, reducing wasteful errors and improving capacity.

-

Finally, A Comprehensive Software Solution Designed for Small Job Shops

Zel X from Siemens is an integrated software application that consolidates collaboration, design, manufacturing, and operations into a comprehensive, easy-to-use solution. From RFQ to delivery, it’s a more efficient way to handle quotes, manage jobs, make parts, and collaborate with teams of all sizes.

-

Diving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

.png;maxWidth=300;quality=90)