VMC Enables Reliable Unmanned Five-Axis Production

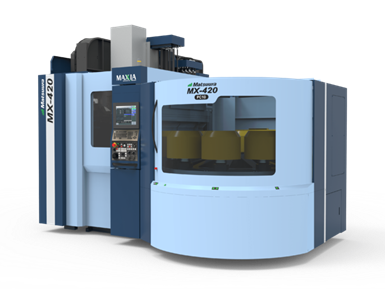

IMTS22: Matsuura showcases a range of machining centers, including the new MX-420 PC10 configured with 10 pallets and 90 tools.

MX-420 PC10. Photo Credit: Matsuura

Matsuura showcases its latest technological innovations and manufacturing solutions, including the new MX-420 PC10 five-axis vertical machining center (VMC), the H.Plus-300 PC15 horizontal machining center (HMC), the MAM72-52V PC15 five-axis VMC and the MAM72-70V PC2 five-axis VMC.

Matsuura recently introduced the MX-420 PC10 configured with 10 pallets and 90 tools. The hand-built, fully automated MX-420 PC10 offers a larger work envelope than the MX-330 PC10 in a compact footprint. The MX-420 PC10 is said to have exceptional ergonomics, intuitive controls and full simultaneous five-axis capability. The MX-420 PC10 is also equipped with the Matsuura G-Tech 31i touch screen with a large display for operator comfort and precise control.

Matsuura is also showcasing its H.Plus-300 PC15 HMC, which reportedly features high speed, rigidity, precision, reliability and low cost of ownership. Equipped with 15 pallets and up to 530 tools, the H.Plus-300 PC15 provides maximized and optimized unmanned production and sustained spindle and machine utilization rates of more than 90%. The H.Plus-300 PC15 delivers solid and robust rigidity for highly accurate metal cutting, along with ATC/APC options to support unmanned operation and flexible manufacturing systems. Offering floor space savings of more than 15%, the H.Plus-300 PC15 has a compact footprint and comes with a host of Maxia spindle choices.

Additionally, Matsuura’s MAM72-52V PC15 enables variable-part/variable-production and extended unmanned operation. Equipped with 130 tools on a 330-tool magazine base, proven tower pallet system (PC15) and chip removal system as standard for extended lights out manufacturing.

Lastly, the MAM72-70V PC2 is a high-speed, large capacity five-axis vertical machining center that can handle larger workpieces than existing MAM72 models and offers faster response times. The MAM72-70V PC2 reportedly delivers higher productivity while delivering pallet and productivity solutions to keep work centers efficiently producing components around the clock.

Matsuura’s Lumex Team will be available to discuss Matsuura’s Metal Additive Manufacturing Service Bureau and its production of 3D metal printed and machined parts. Matsuura is now offering quick-turn prototyping, producing a wide range of parts including unique functional prototypes and low- to mid-volume production runs.

Related Content

-

Volumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

-

Heavy Engineering: The Complex Logistics of Moving Large Machine Tools

One of our fascinations with large-format machine tools has little to do with their capabilities, but everything to do with the logistics involved with getting them up and running. Here’s how one of the world’s oldest builders of giant machine tools tackles the challenge.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)