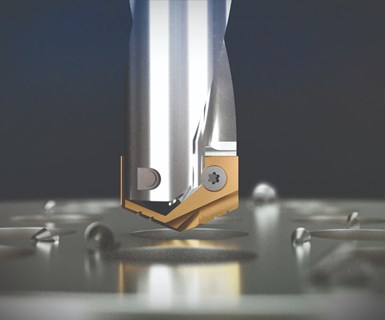

YG-1's SV-Point Spade Drill Enables Higher Feeds and Speeds

YG-1’s SV-Point spade drill inserts are said to provide longer tool life at higher spindle speeds and feeds than conventional spade drills.

YG-1’s SV-Point spade drill inserts are said to provide longer tool life at higher spindle speeds and feeds than conventional spade drills. The inserts are designed for a range of applications and materials including steel, stainless steel and cast iron.

The SV-Point’s H-Coating offers high heat and wear resistance. Sinusoidal thinning edge enables smooth cutting and improves centering, while a positive rake angle improves hole finish. Imparting low thrust force, the tool is an effective option for underpowered machines, the company says.

Three material options are available, including:

- Super Cobalt (T15), designed for improved tool life and performance compared to standard high speed steel inserts, with a size range of 9.5 to 114.3 mm;

- Premium Cobalt (M48), providing extended tool life compared to T15 in harder materials, with a size range of 9.5 to 114.3 mm; and

- Carbide C5 (P40), designed for longer tool life and faster speeds and feeds in rigid setups, with a size range of 9.5 to 47.6 mm.

Related Content

-

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.