Search Results

Showing 1 – 10 of 4137 resultsThe VPick and VPack robotic palletizing and depalletizing solutions use AI vision systems to enhance warehouse efficiency and reliability.

The new High Rail Gantry Machines offer high-speed cutting capabilities, high precision rates and the ability to handle high-volume machining tasks.

The Platform 3 series of modular grinding machines is designed to provide increased flexibility and cost-effectiveness.

Altera C HA ceramic-bridge CMMs provide volumetric accuracy from 1.3+L/350, repeatability from 0.0013 mm and scanning accuracy from 0.002 mm.

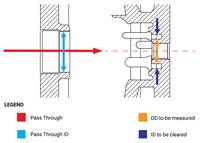

Fixed-body mechanical plug gages provide fast, high-performance measurement for tight-tolerance holes.

The MF3048HL combined punch press and fiber laser provides precise cutting, punching, tapping and forming operations on a diverse range of materials.

Muratec’s technology has marked turning points in automation, helping customers enhance competitive efficiencies across diverse industries.

The G 160 and G 250 gear-profile grinding machines provide short chip-to-chip times, intelligent axis concepts as well as thermal and mechanical stability.

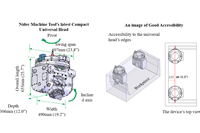

The compact universal head enables better accessibility between the tool and the workpiece, as well as improved surface-finish quality, greater motion range and high-efficiency machining under ideal machining conditions.

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.