Published

Last Glance at IMTS 2010

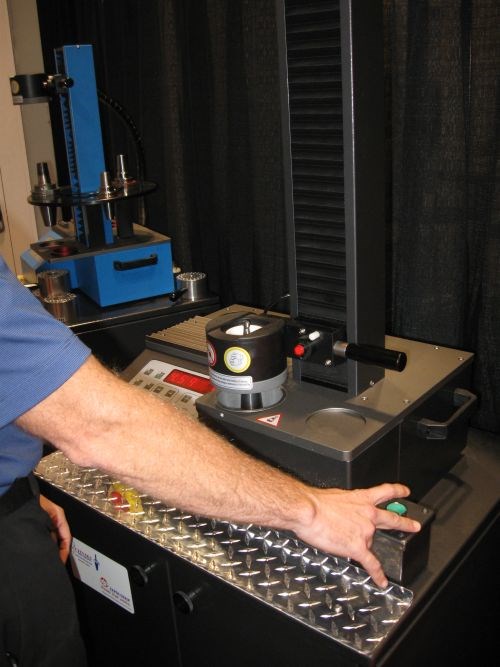

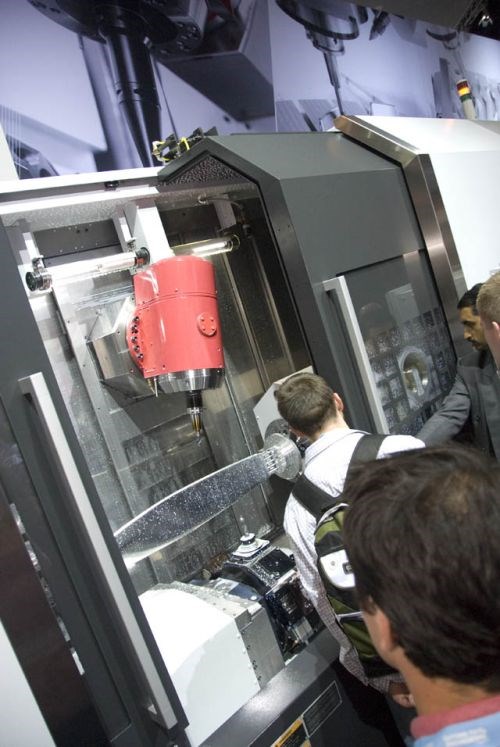

It would be impossible to cover all of the key exhibitors at IMTS 2010—even if every booth got merely a quick glance. However, the editors of MMS did get glimpses of some interesting technologies exhibited at the show...

It would be impossible to cover all of the key exhibitors at the 2010 International Manufacturing Technology Show (IMTS)—even if every booth got merely a quick glance.

However, the editors of MMS did get glimpses of some rather interesting technology exhibited at the show, so we are sharing examples here. Of course, this sampling takes merely a glancing blow at disclosing the huge cache of new techniques, new processes, new machines, new controls and new cutting tools that were on display.

.png;maxWidth=300;quality=90)