Formlabs

35 Medford St.

Ste. 201

Somerville, MA 02143 US

617-702-8476

formlabs.com

About Formlabs

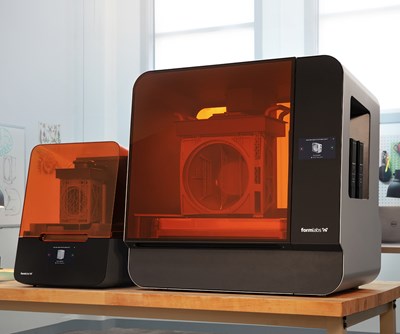

A 3D printing technology developer and manufacturer of the Form 2 SLA 3D printer, Fuse 1 SLS 3D printer and a variety of high-performance materials additive manufacturing materials. Formlabs is establishing the industry benchmark in professional 3D printing.

IS THIS YOUR COMPANY?

Video Gallery

Formlabs Keynote Highlights

Watch the highlights of Formlabs' keynote in which CEO and co-founder Max Lobovsky unveils the next generation of SLA 3D ...

Form 4 Reveal | Formlabs Keynote

Formlabs CEO and co-founder Max Lobovsky unveils the next generation of SLA 3D printers, Form 4. Learn about how Form 4 will ...

Formlabs Form 4 Beats Injection Molding Machine in Speed and Quality

Catch the thrilling speed showdown between Injection Molding and the Form 4 3D Printer by Formlabs! Learn more: ...

Form 4: A Closer Look at Its Design

Get up close with the sleek design and impressive features of our brand new printer, Form 4! From its smooth curves to its ...